Spraying device used for pipeline repairing and use method of spraying device

A technology for repairing spraying devices and pipelines, which is applied to spraying devices with movable outlets, spraying devices, etc., can solve the problems of electric motors, such as the danger of using electric motors, and achieve the effect of structural optimization and construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

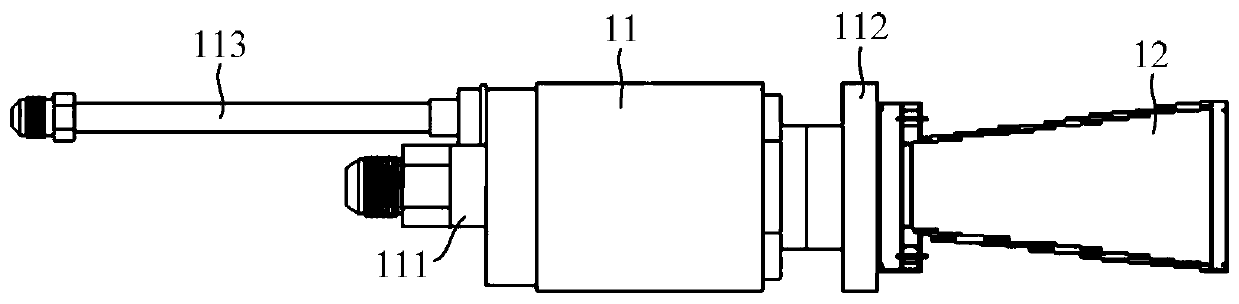

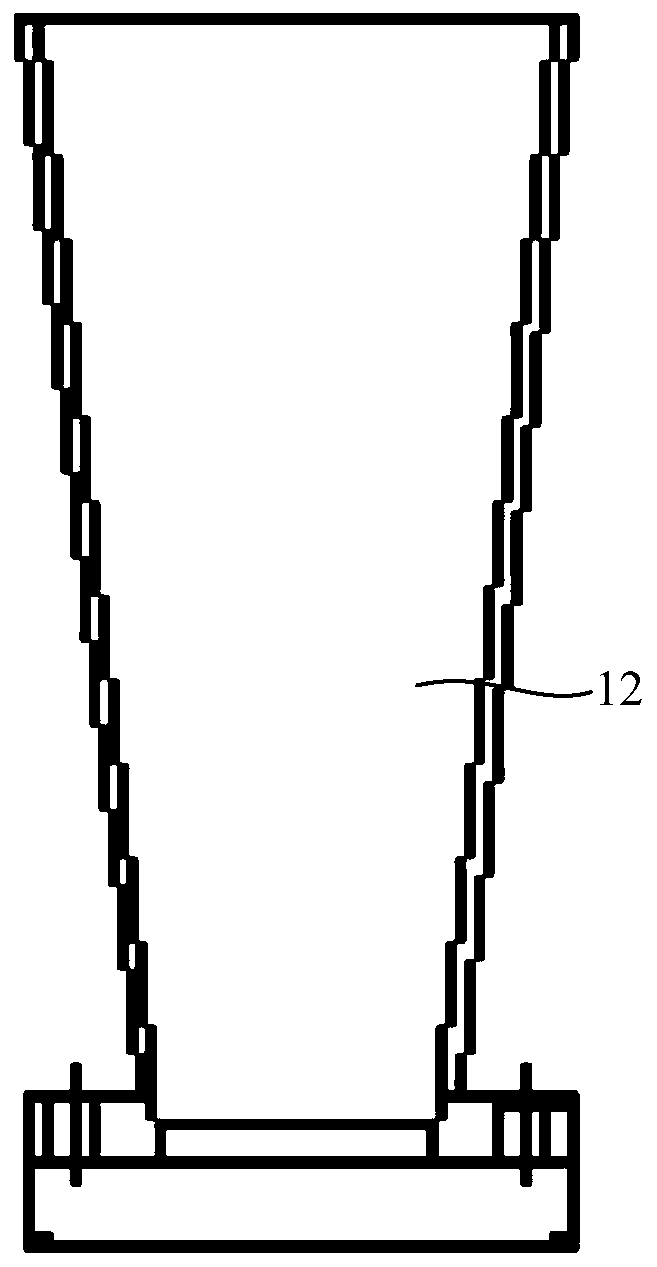

[0050] The air motor 11 is installed on the discharge end of the feed pipe, and the feed pipe is connected with the communication pipe 111, and then the rotary cup 12 is installed at the other end of the air motor 11, and the communication pipe 111 is connected with the inside of the rotary cup 12;

[0051] Pass compressed air into the air motor 11 from the intake pipe 113 to drive the rotating part 112 of the air motor to rotate and drive the rotary cup 12 to rotate, and then feed the rotary cup 12, so that the paint is passed into the rotary cup 12 from the communication pipe 111;

[0052] Extend the spraying device into the pipeline, and the gas in the air motor 11 is sprayed out from the gas outlet 114;

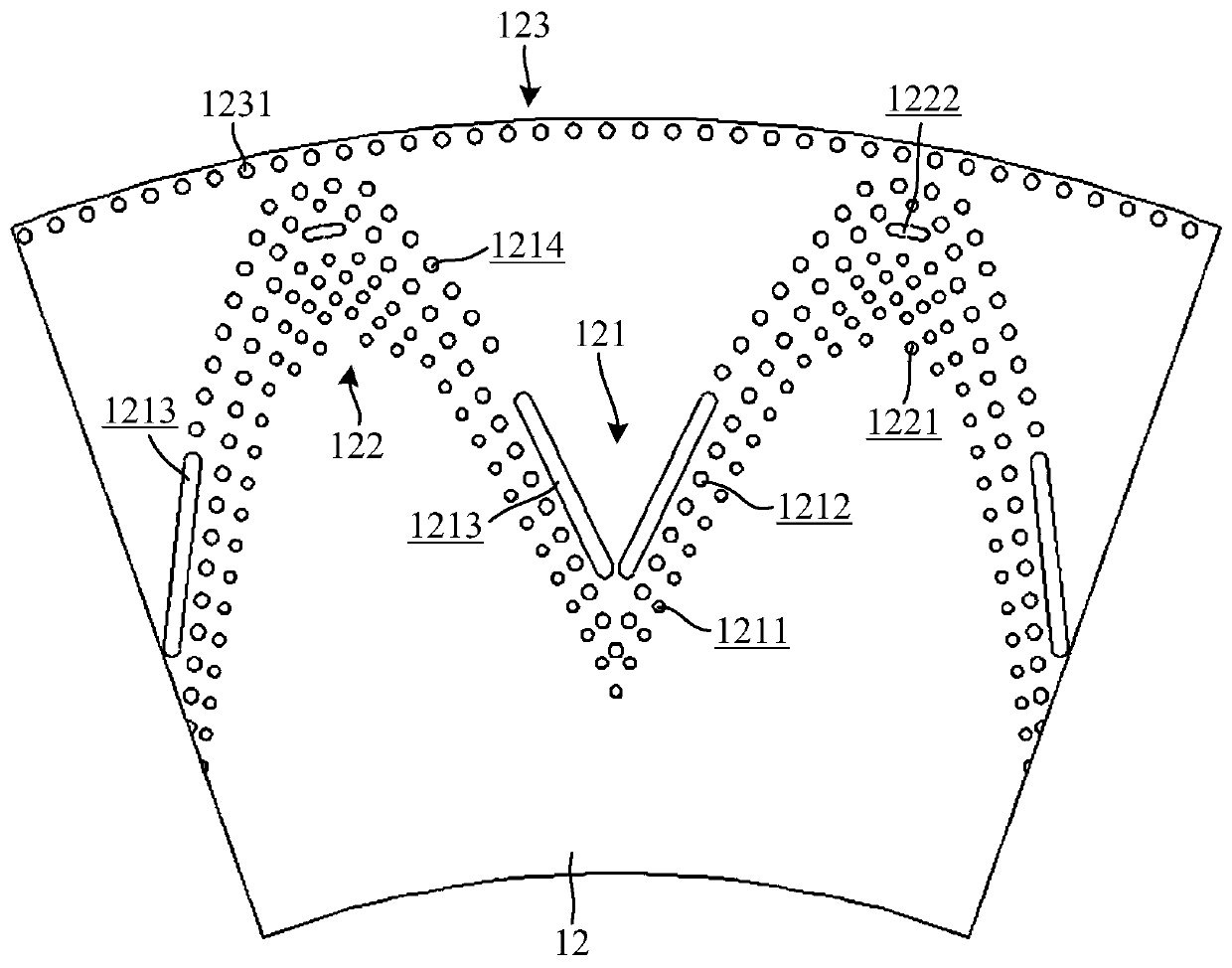

[0053] After the paint enters the high-speed rotating cup 12, it is atomized at a position below 1 / 3 of the height of the cup 12. Shaped hole section 122 is sprayed outwards, and the remaining small amount of paint is sprayed outwards from annular hole section 123, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com