A construction waste gravel production line

A construction waste and production line technology, which is applied in the direction of solid separation, cleaning methods and appliances, chemical instruments and methods, etc., and can solve the problems of large floor space of construction waste gravel production lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

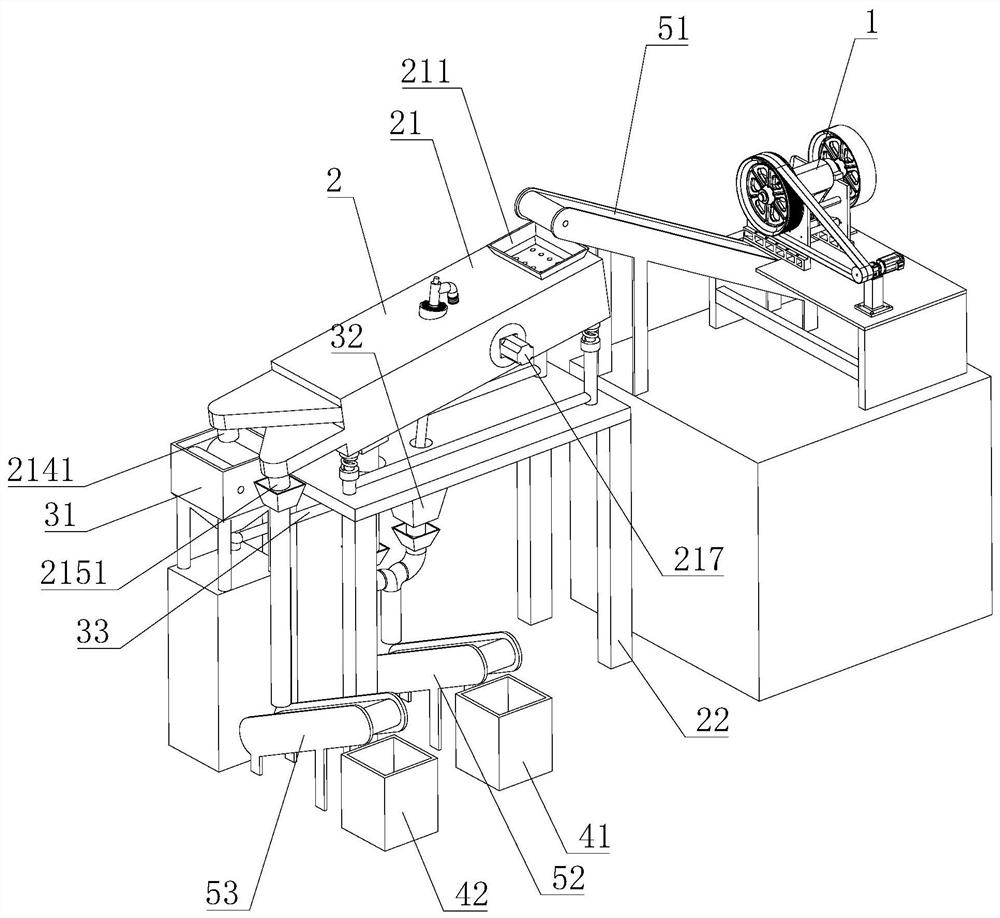

[0041] See attached figure 1 , a construction waste crushing production line includes a primary crusher 1 , a screening machine 2 , a secondary crusher, a fine material bin 41 and a coarse material bin 42 . In this embodiment, the primary rock crusher 1 is a jaw crusher.

[0042] The screening machine 2 includes a vibrating screen box 21 , an underframe 22 and an elastic support assembly arranged between the vibrating screen box 21 and the underframe 22 .

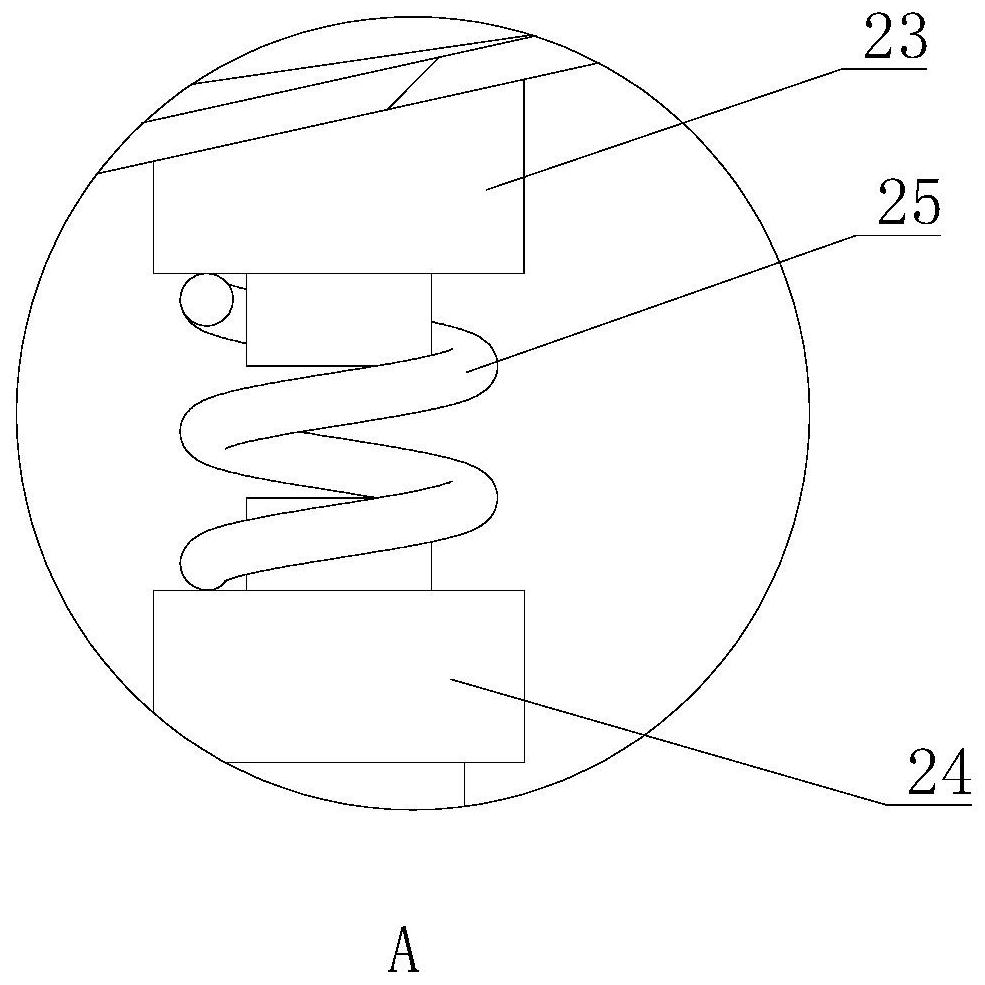

[0043] See attached figure 2 And attached image 3 The elastic support assembly is an upper support plate 23 fixed on the outer side wall of the vibrating screen box 21, a lower support plate 24 arranged in contact with the upper support plate 23 and supported between the upper support plate 23 and the lower support plate 24 The support spring 25. Wherein, both the upper support plate 23 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com