Roller crusher with adjustable transmission efficiency

A technology of transmission efficiency and crusher, which is applied in the direction of grain processing, etc., can solve the problems of affecting service life and crushing effect, single crushing thickness specification, rapid wear of rollers, etc., and achieve simple structure, improved crushing effect, and fast crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will now be described in further detail in conjunction with the accompanying drawings and examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention. The structures, connections and methods not described in detail in the patent of the present invention can be understood as common knowledge in the field. In addition, it should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and " "Outward" refers to a direction toward or away from the geometric center of a particular component, respectively.

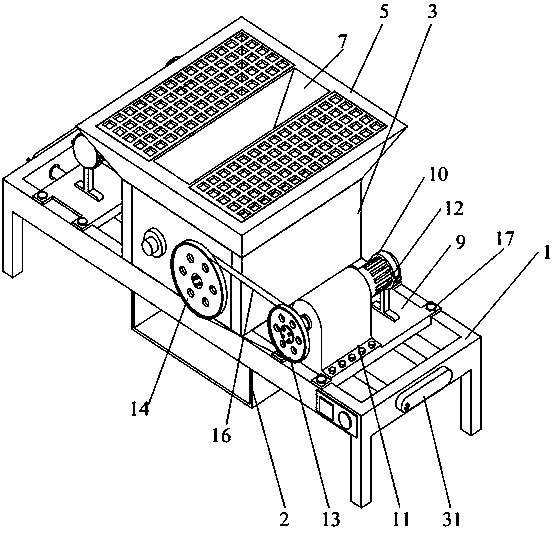

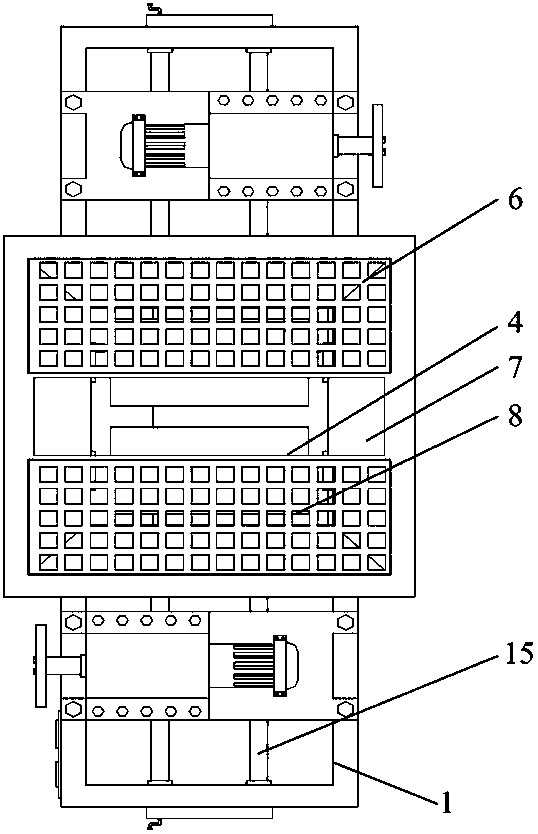

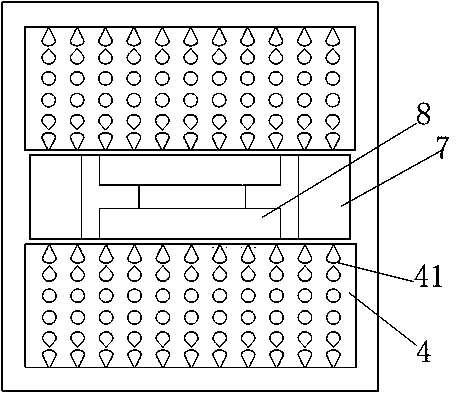

[0022] Such as Figure 1-4 As shown, the roller crusher with adjustable transmission efficiency includes bracket 1, blanking box 2, crushing box 3, crushing roller 4, feeding box 5, driving device 12, driving wheel 13, driven wheel 14, position adjustment Mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com