Cotton ginning device capable of preventing negative pressure and realizing efficient flow guide

An anti-negative pressure and high-efficiency technology, applied in the separation of plant fibers from seeds, textiles and papermaking, mechanical treatment, etc., can solve the problems affecting the production efficiency of cotton gins, the separation of unfavorable fibers and impurities, and the waste of effective fibers, so as to save cotton resources, improve the quality of fiber appearance, and the effect of high power consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

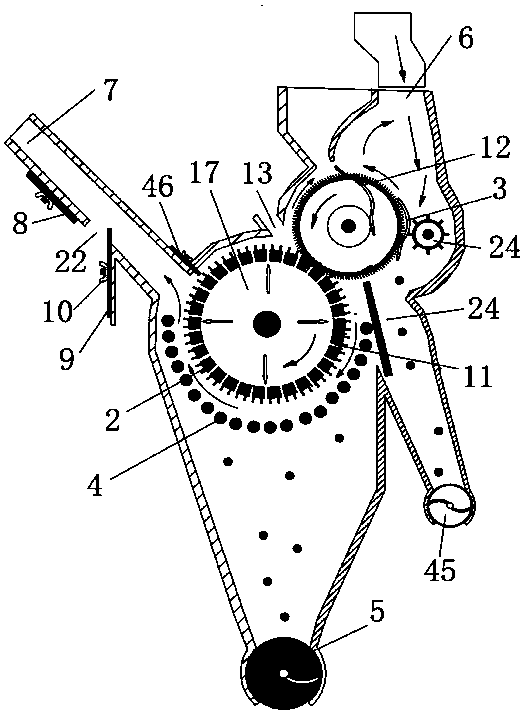

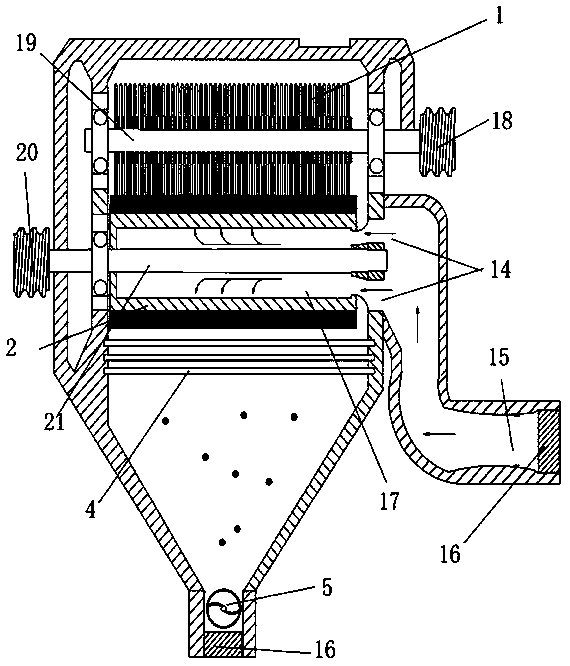

[0039] Example 1: Fig. 1 and Fig. 2 are structural schematic diagrams of the technical solution of the present invention applied to a cotton gin. As shown in the figure, the cotton gin is composed of a shell, a seed cotton input part, a cotton seed and fiber separation part, a fiber and impurity separation part, etc. , the front end of the shell is provided with a working box 6, the outlet end is a cotton outlet 7, and the shell adopts a closed structure to prevent seed cotton, impurities, dust and free fibers from overflowing the gin; The fiber separation part is composed of saw roller 1, rib 12, brush roller 2, seed dripping board 23 and seed row spiral 45, saw roller 1 is a saw roller composed of a single saw blade and a spacer ring On the saw roller shaft 19, the brush roller is fixed on the brush faceplate for a brush strip, and the faceplate is set on the brush roller shaft 21 and one or both ends of the roller are forward air ducts 13; Bar grid 4, lower miscellaneous di...

Embodiment 2

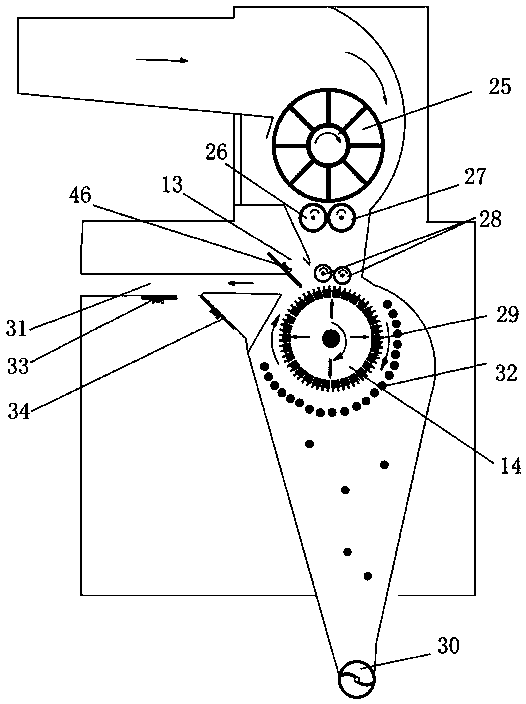

[0045] Embodiment 2: Embodiment 2 is to apply the technical solution of the present invention to a brush type lint (lint) cleaning machine. Fig. 3 is a schematic structural diagram of a wool-type lint (lint) cleaning machine, as shown in the figure, the lint cleaning machine includes a cotton collecting dust cage 25, a stripping roller 26, a cotton pressing roller 27, a cotton feeding roller 28, and a lint cleaning machine The brush roller 29, the miscellaneous discharge screw or miscellaneous suction port 30 under the lint cleaning machine, the cotton outlet 31 of the lint cleaning machine, the miscellaneous grid bar 32 of the lint cleaning machine, the supplementary air regulating plate 33 of the lint cleaning machine and the lint cleaning machine The air pressure adjusting plate 34 and the brush roller windshield 46. Simultaneously adopt the same air induction technical scheme as in embodiment 1. That is, one or both ends of the brush roller 29 of the lint cleaning machine...

Embodiment 3

[0047] Embodiment 3: Embodiment 3 is to apply the technical solution of the present invention to a brush type depilling machine. Fig. 4 is a structural schematic diagram of the cashmere stripping machine, as shown in the figure, the cashmere stripping machine includes the cashmere stripping machine working box 35, the seed roller 36, the cashmere stripping rib 37, the cashmere stripping machine saw blade roller 38, the brush of the cashmere stripping machine Roller 39, stripping machine miscellaneous grill bar 40, miscellaneous discharge spiral or miscellaneous suction port 44 under the stripping machine, short fleece outlet 41, air pressure regulating plate 43 of the stripping machine and air supply regulating plate 42 of the stripping machine . Simultaneously adopt the same air-inducing technical scheme as embodiment 1, that is, at one or both ends of the hair brush roller 39 of the cashmere stripping machine, advance air duct 13 is established, and the hair brush roll 39 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com