Chemically strengthened glass, and preparation method and application thereof

A glass-strengthening and chemical technology, applied in the field of chemically-strengthening glass and its preparation, can solve problems such as glass strength reduction and self-explosion, and achieve the effect of improving drop performance and increasing atomic gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The second aspect of the present invention provides a method for preparing chemically strengthened glass, comprising: after mixing the raw materials for preparing the chemically strengthened glass, sequentially melting, forming, annealing and cooling, and cutting to obtain original glass;

[0057] Putting the original glass into a strengthening solution for chemical strengthening to obtain a chemically strengthened glass; wherein, the chemical strengthening process includes at least lithium-sodium exchange and sodium-potassium exchange;

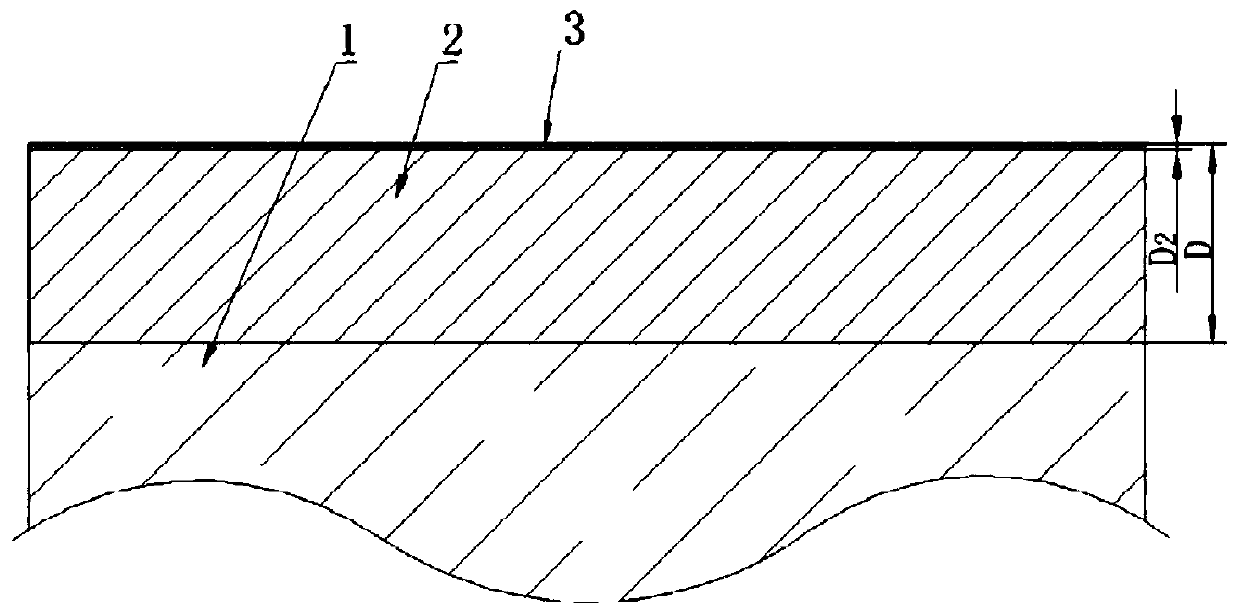

[0058] The chemically strengthened glass has an ion exchange layer with a depth D obtained through the chemical strengthening, wherein 250 μm≤D≤350 μm;

[0059] Relative to the original glass, K in the ion exchange layer 2 The average increase of O is 0.1% to 0.25% by weight, preferably 0.12% to 0.23% by weight.

[0060] The meaning of including at least lithium-sodium exchange and sodium-potassium exchange above is that one or more l...

Embodiment 1-8 and comparative example 1-11

[0091] The raw materials and content in the following examples and comparative examples are shown in Table 1 below, the process parameters (i.e. strengthening temperature and time) of the chemical strengthening process are shown in Table 2 below, and the performance test data of the glass made in the following examples and comparative examples As shown in Table 2 below. The preparation process in the following examples and comparative examples is for example:

[0092] The preparation method of chemically strengthened glass is:

[0093] 1) Preparation of raw glass:

[0094] Proportioning is carried out according to the component ratio of each raw material. At the same time, put the mixed raw materials into a sealed bag, mix them evenly in the sealed bag, and then pour them into a platinum crucible to melt, melt, pour the molten glass liquid into a metal mold, and Put the glass together with the metal mold into the annealing furnace for precision annealing and cooling. The ann...

Embodiment 6

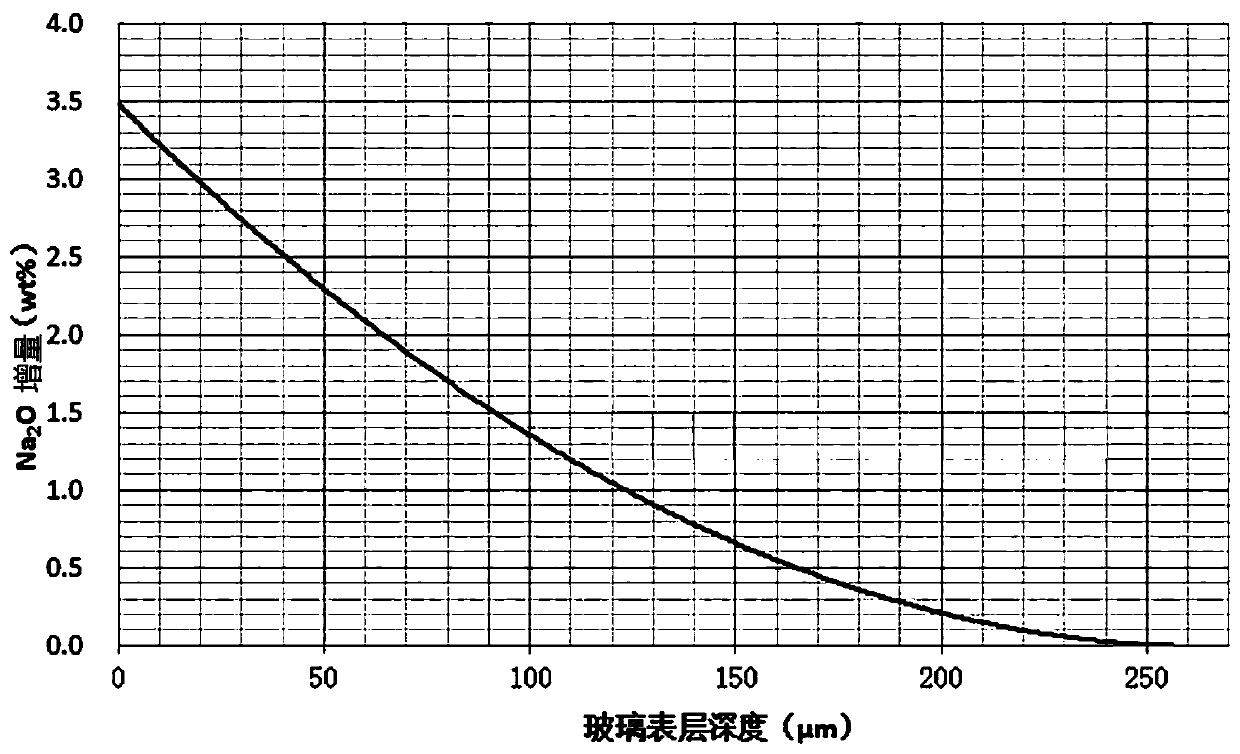

[0107] The Na of the glass section that obtains after lithium-sodium exchange among the embodiment 6 2 The change curve of O increment is as follows figure 2 As shown, the abscissa is the depth of the glass surface, that is, the lithium-sodium exchange layer depth D of the glass obtained by lithium-sodium exchange 1 , the fitting equation of the curve is y=0.00002x 2 -0.0144x+2.9953, when Na 2 When the O increment is 0, the surface depth value of the glass is the boundary between the original glass and the lithium-sodium exchange layer, thus obtaining the depth value D of the lithium-sodium exchange layer 1 , the curve fitting equation is integrated to obtain the total increment in the lithium-sodium exchange layer, and the total increment is divided by the depth D of the lithium-sodium exchange layer 1 , that is, Na in the lithium-sodium exchange layer 2 Average increment of O.

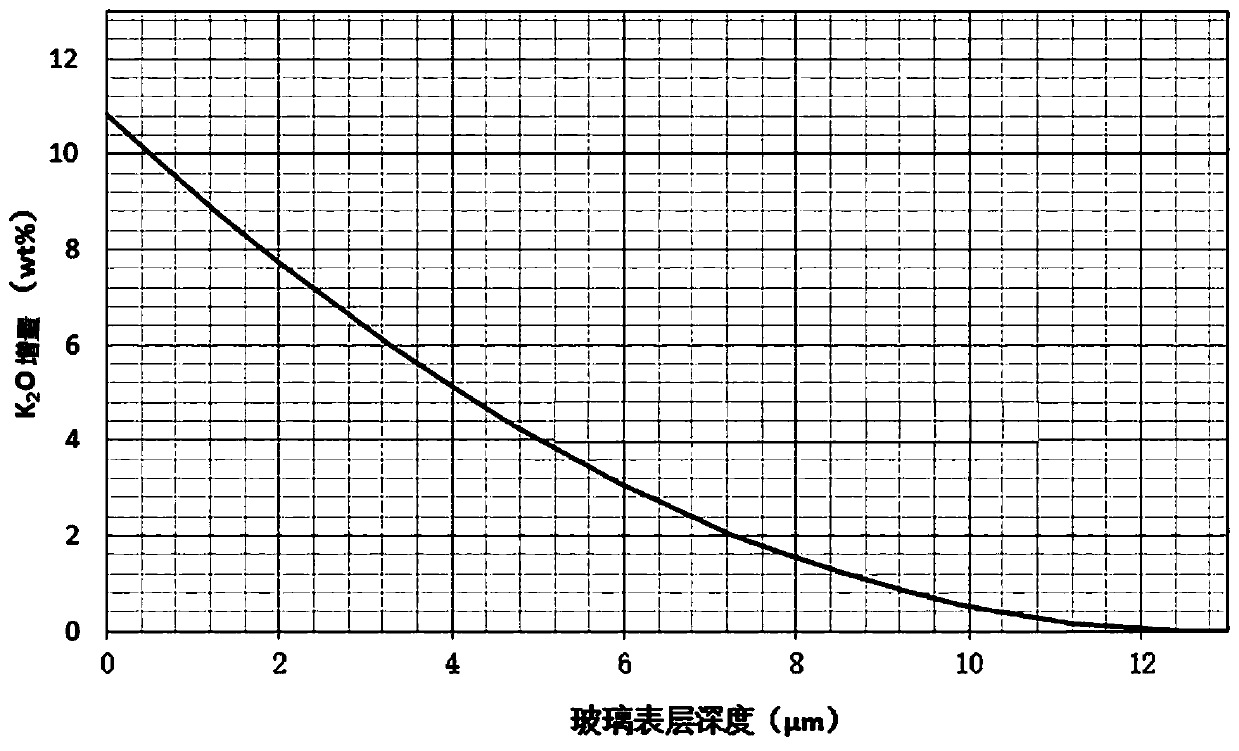

[0108] K of the chemically strengthened glass section after sodium potassium exchange in em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com