Thermal printer with open paper bin

A thermal printer, an open technology, used in typewriters, printing devices, printing, etc., can solve the problems of inconvenience caused by printer movement and affect work efficiency, and achieve a wide range of operating angles, improve work efficiency, and facilitate handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

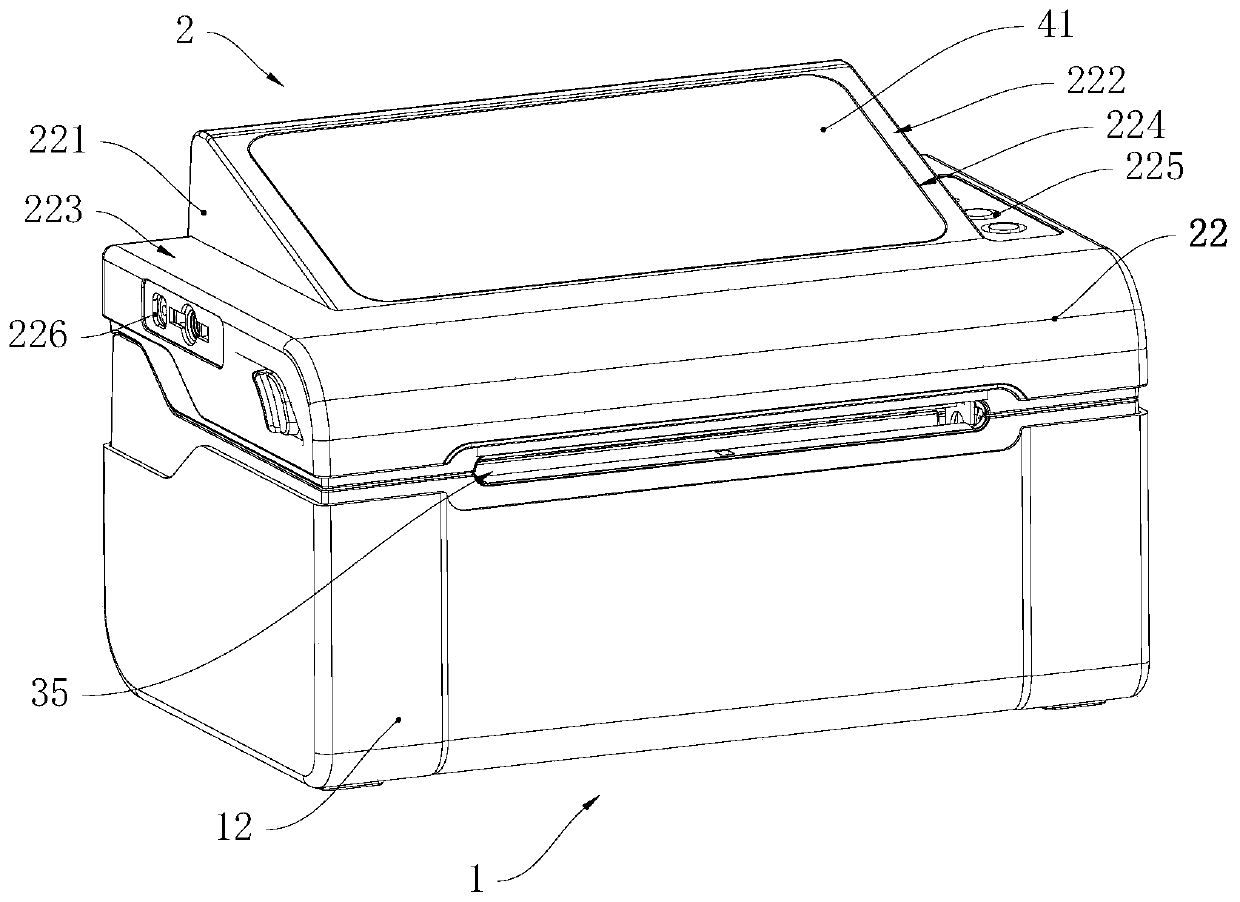

[0048] In embodiment two, see Figure 8 and Figure 9 The touch screen 41 covers the side wall of the cover 22 away from the housing assembly 1, and the side wall of the cover 22 away from the housing assembly 1 is arranged obliquely. The inclination of the touch screen 41 makes the operating angle range wider, and the operation More convenient.

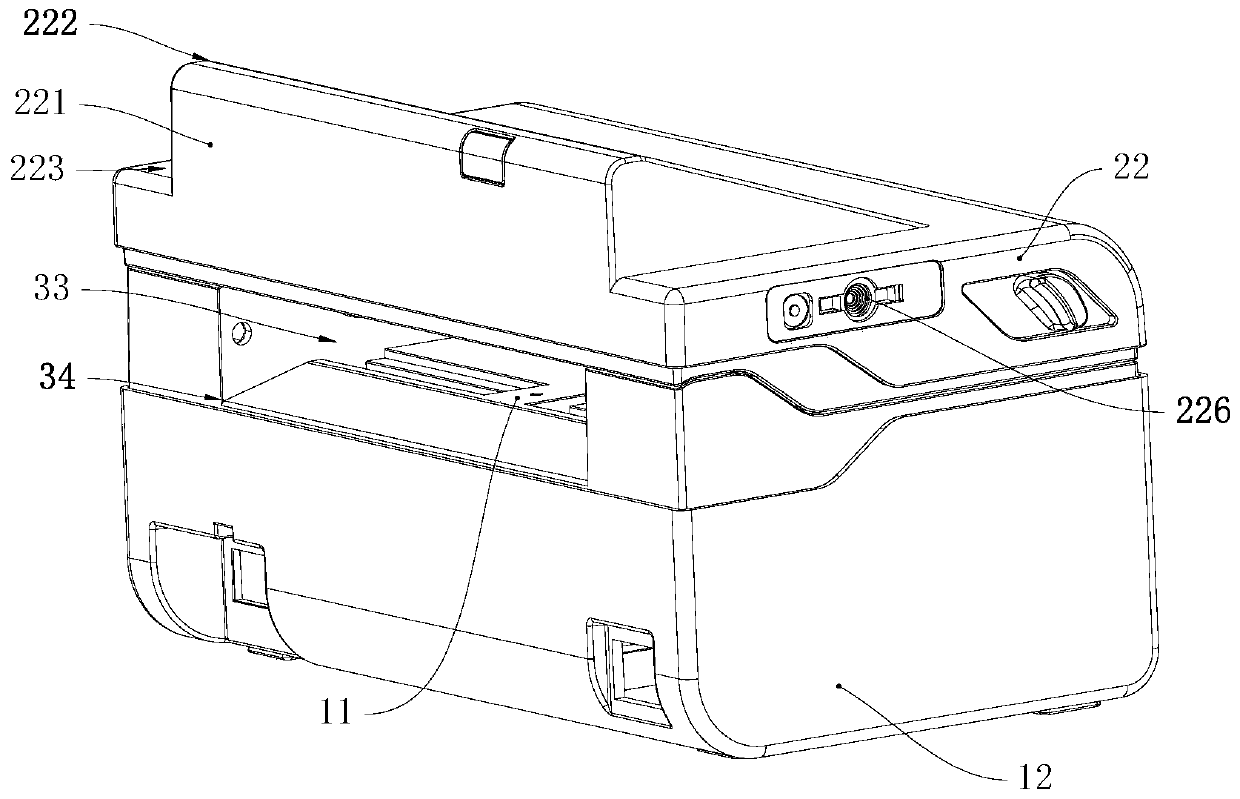

[0049] In this embodiment, the first middle frame 11 is provided with an inclined surface 10 on the side facing the paper inlet opening 34, and the inclined surface 10 is inclined toward the second middle frame 21 from the paper inlet opening 34 to the paper outlet opening 35, so as to achieve The height of the paper opening 34 is greater than that of the paper output opening 35 .

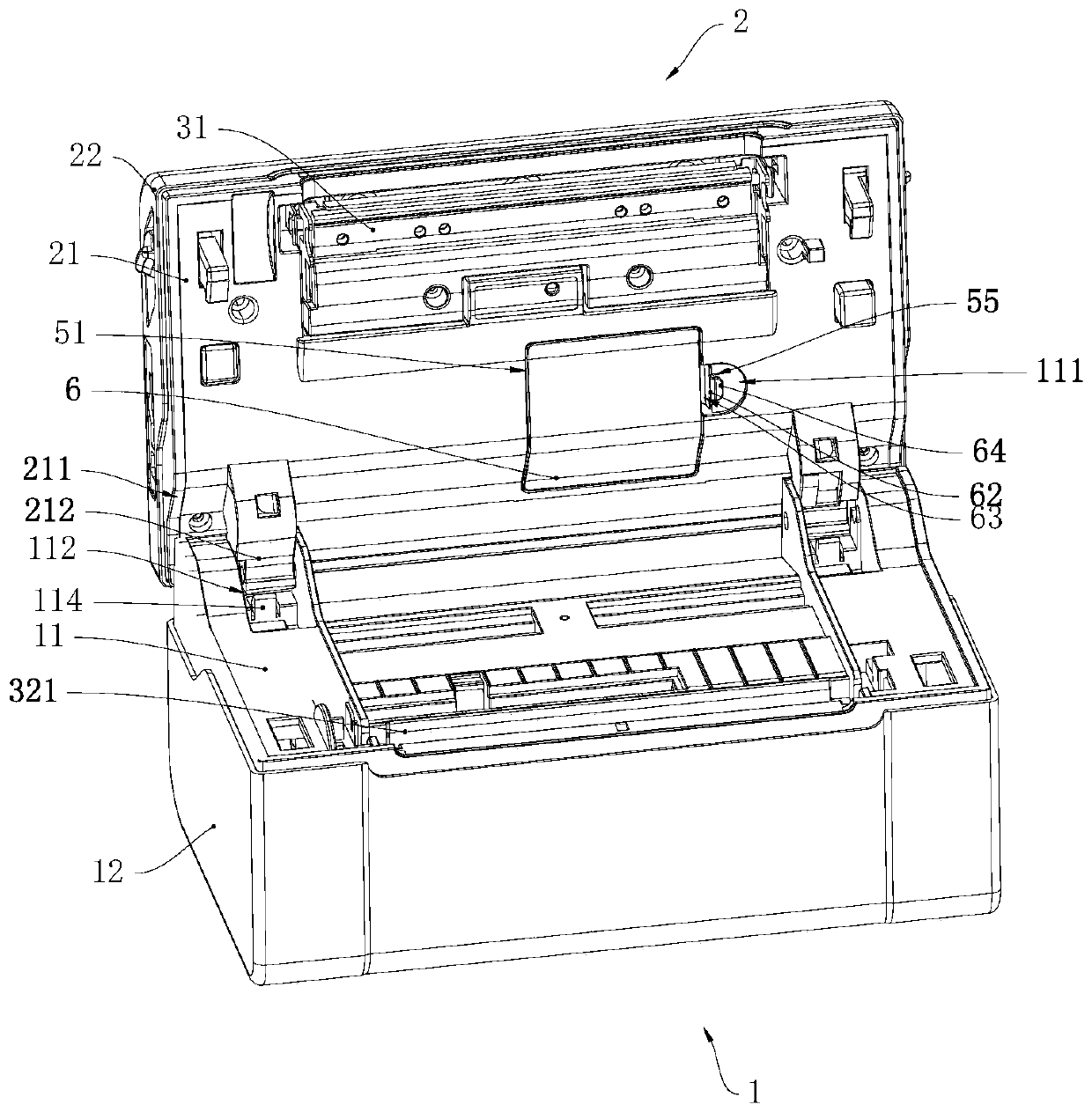

[0050] In this embodiment, the rubber roller 32 is disposed on the side of the first middle frame 11 facing the second middle frame 21 , and the thermal sheet 31 is disposed between the second middle frame 21 facing the first middle frame 11 . The ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com