Choline particle and preparation method and application thereof

A technology of choline and granules, which is applied in the field of choline granules and its preparation, can solve the problems of increased use cost, poor friability, and high explosion-proof requirements, and achieve high practicability, moderate particle size, and good particle fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

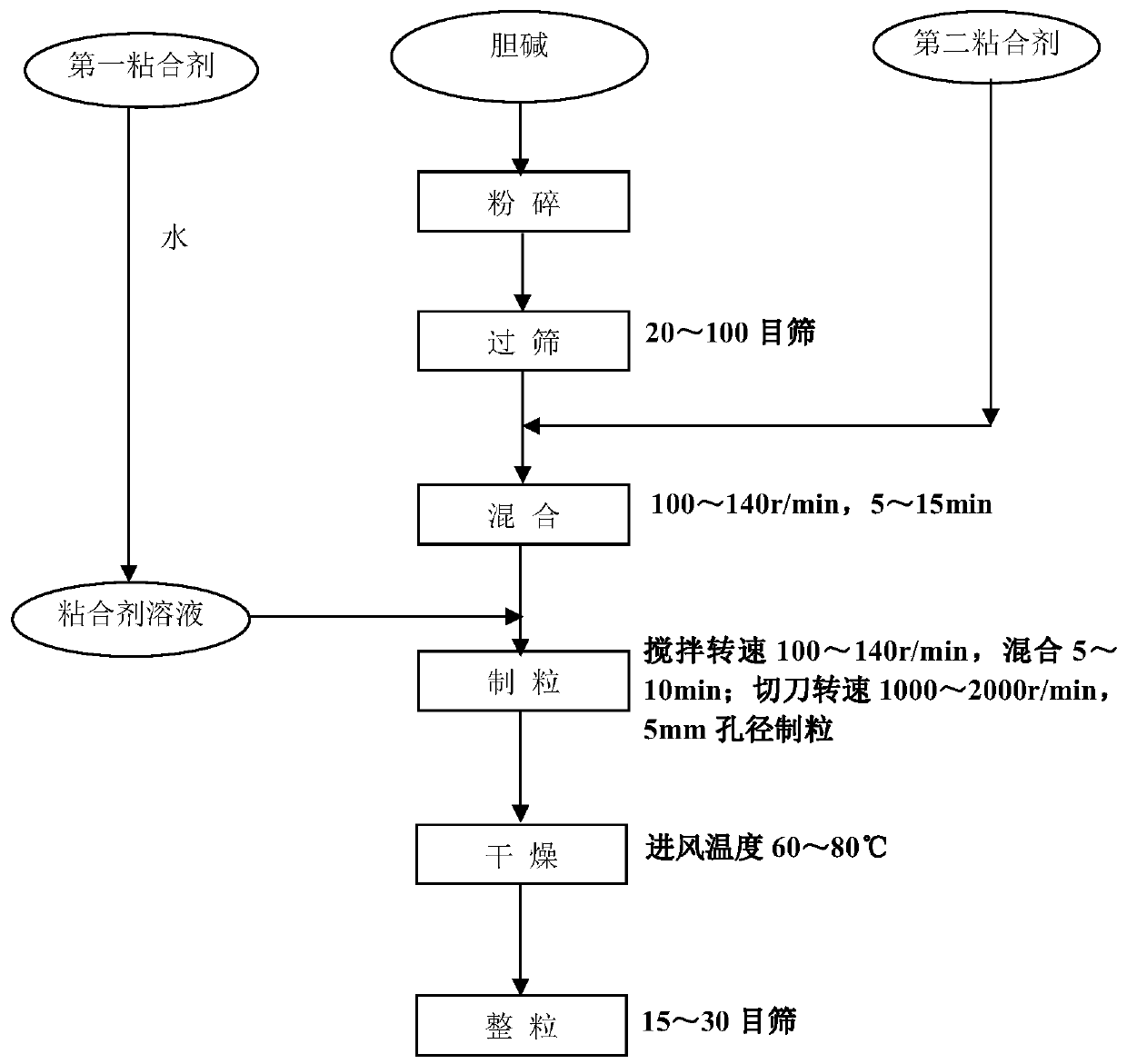

Method used

Image

Examples

Embodiment 1

[0030] 1. Crush the choline bitartrate through a 20-mesh sieve for later use.

[0031] 2. Dissolve hydroxypropyl methylcellulose in water to make a solution with a concentration of 4%.

[0032] 3. Take 2 parts of crushed and sieved choline bitartrate, add 1 part of low-substituted hydroxypropyl cellulose, place in a high-speed shear wet mixing granulator, and mix for 5 minutes under the condition of 100r / min; add hydroxypropyl cellulose 0.1 part of propyl methylcellulose solution was granulated, and the granulation conditions were mixed for 5 minutes at a stirring speed of 100r / min; then the material passed through a sieve with an aperture of 5mm, and was processed by a granulator with a rotating speed of 1000r / min. grain.

[0033] 4. Put the wet granules into the fluidized bed for drying. Drying conditions: air inlet temperature 60°C, stop drying when the granule moisture reaches (2±0.5)%, take out the material and granulate through a 15-mesh sieve to obtain dry Granules, t...

Embodiment 2

[0035] 1. Grind the choline bitartrate through a 40-mesh sieve for later use.

[0036] 2. Dissolve hydroxypropyl methylcellulose in water to make a solution with a concentration of 6%.

[0037] 3. Take 4 parts of crushed and sieved choline bitartrate, add 2 parts of low-substituted hydroxypropyl cellulose, place in a high-speed shear wet mixing granulator, and mix for 10 minutes under the condition of 120r / min; add hydroxypropyl cellulose 1 part of propyl methylcellulose solution was granulated, granulation conditions: mixed for 10 minutes at a stirring paddle speed of 120r / min; then the material passed through a sieve with a pore size of 5mm, and was processed by a granulator with a rotating speed of 1500r / min. grain.

[0038] 4. Put the wet granules into the fluidized bed for drying. Drying conditions: air inlet temperature 70°C, stop drying when the granule moisture reaches (2±0.5)%, take out the material and granulate through a 20-mesh sieve to obtain dry Granules, that ...

Embodiment 3

[0040] 1. Crush the choline bitartrate through a 60-mesh sieve for later use.

[0041] 2. Dissolve hydroxypropyl methylcellulose in water to make a solution with a concentration of 8%.

[0042] 3. Take 6 parts of crushed and sieved choline bitartrate, add 3 parts of low-substituted hydroxypropyl cellulose, place in a high-speed shear wet mixing granulator, and mix for 15 minutes under the condition of 140r / min; add hydroxypropyl cellulose Dissolve 2 parts of propyl methylcellulose and granulate. Granulation conditions: Mix for 15 minutes at a stirring paddle speed of 140r / min; then the material passes through a sieve with a pore size of 5mm, and is granulated by a granulator with a speed of 2000r / min. grain.

[0043] 4. Put the wet granules into the fluidized bed for drying. Drying conditions: air inlet temperature 80°C, stop drying when the granule moisture reaches (2±0.5)%, take out the material and pass through a 30-mesh sieve for granulation to obtain dry Granules, that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com