Preparation method of haw jelly rich in diced pomelo skin

A technology of pomelo peel and haw jelly, applied in confectionary, confectionary industry, food science, etc., can solve the problems of not being effectively developed and utilized, achieve high nutritional and health value, reduce environmental pollution, and enrich varieties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

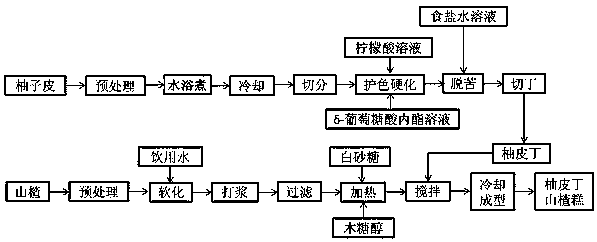

Method used

Image

Examples

Embodiment 1

[0022] Put the pretreated pomelo peel in a stainless steel container, add drinking water to immerse the grapefruit peel, boil in water for 10 minutes in a constant temperature water bath at a temperature of 90 ℃, to inactivate the enzyme in the pomelo peel; cool to room temperature, and use a stainless steel knife Cut the pomelo peel into 1cm×2cm strips; prepare a citric acid solution with a mass fraction of 0.5% and a δ-gluconolactone solution with a mass fraction of 1%, and place the pomelo peel in a volume ratio of 1:1 (citric acid solution: δ-gluconolactone solution) soaked in the mixed solution for 2 h to protect and harden it; remove the pomelo peel and wash it with water, and put the pomelo peel in 8% saline solution Precooked at 80 ℃ for 13 minutes and soaked for 3 hours for debittering treatment; after cooling, the pomelo peel was cut into cubes with a uniform surface area of 1 mm×1 mm to obtain diced pomelo peel;

[0023] Put the pretreated hawthorn in a container,...

Embodiment 2

[0026] Put the pretreated grapefruit peel in a stainless steel container, add drinking water to submerge the grapefruit peel, and heat it in a constant temperature water bath at 95 °C for 15 minutes to inactivate the enzyme in the grapefruit peel; cool to room temperature, and use a stainless steel knife to remove Cut the pomelo peel into 1 cm×3 cm strips; prepare a citric acid solution with a mass fraction of 0.64% and a δ-gluconolactone solution with a mass fraction of 1.65%, and place the pomelo peel in a volume ratio of 1:1 (lemon acid solution: δ-gluconolactone solution) in a mixed solution for 2 h for color protection and hardening treatment; remove the pomelo peel and wash it with water, and wash the pomelo peel in a 6% saline solution Precooked at 70 ℃ for 13 minutes and soaked for 3 hours for debittering treatment; after cooling, the pomelo peel was cut into cubes with a uniform surface area of 5 mm×5 mm to obtain diced pomelo peel;

[0027] Put the pretreated hawth...

Embodiment 3

[0030] Put the pretreated grapefruit peel in a stainless steel container, add drinking water to immerse the grapefruit peel, heat it in a constant temperature water bath at 100 °C for 10 minutes, and inactivate the enzyme in the grapefruit peel; cool to room temperature, and use a stainless steel knife to remove Cut the pomelo peel into 2cm×5 cm strips; prepare a citric acid solution with a mass fraction of 0.8% and a δ-gluconolactone solution with a mass fraction of 2%, and place the pomelo peel in a volume ratio of 1:2 (citric acid Solution: soak in the mixed solution of δ-gluconolactone solution) for 2 h to protect and harden it; remove the pomelo peel and wash it with water, and put the pomelo peel in a 4% salt solution Pre-boiled at 60 ℃ for 13 minutes and soaked for 3 hours for debittering treatment; after cooling, the pomelo peel was cut into cubes with a uniform surface area of 3 mm×3 mm to obtain diced pomelo peel;

[0031] Put the pretreated hawthorn in a container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com