A method for online monitoring and traceability of common parts of continuous casting machine based on digital twin

A technology for general parts and continuous casting machines, applied in data processing applications, registering/indicating the work of machines, instruments, etc., can solve the problems of different remaining life, performance degradation of general parts, etc., and achieve the effect of high flexibility and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] The present invention is a digital twin-based online monitoring and traceability method for common parts of continuous casting machines, which specifically includes the following steps:

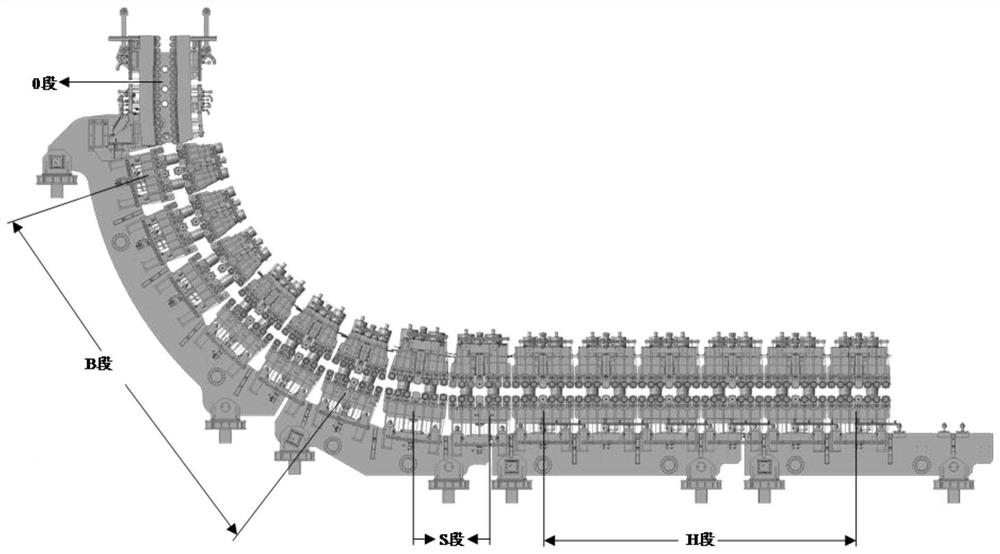

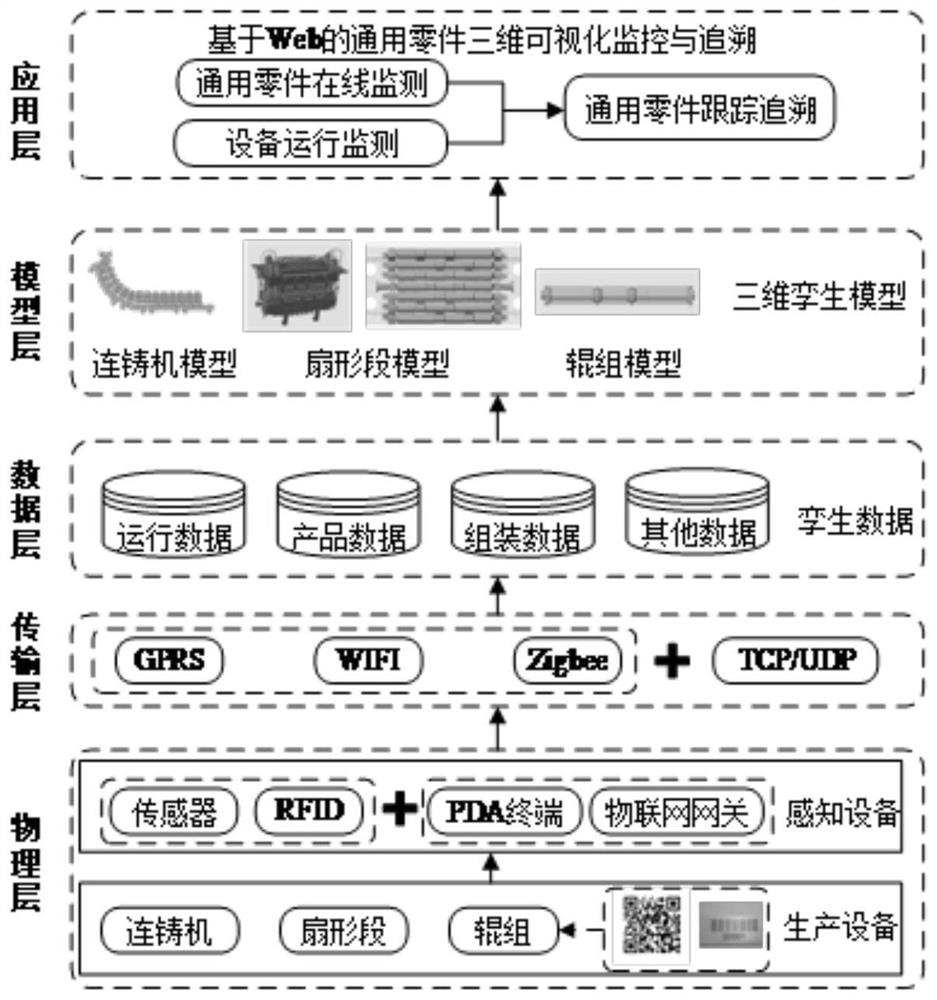

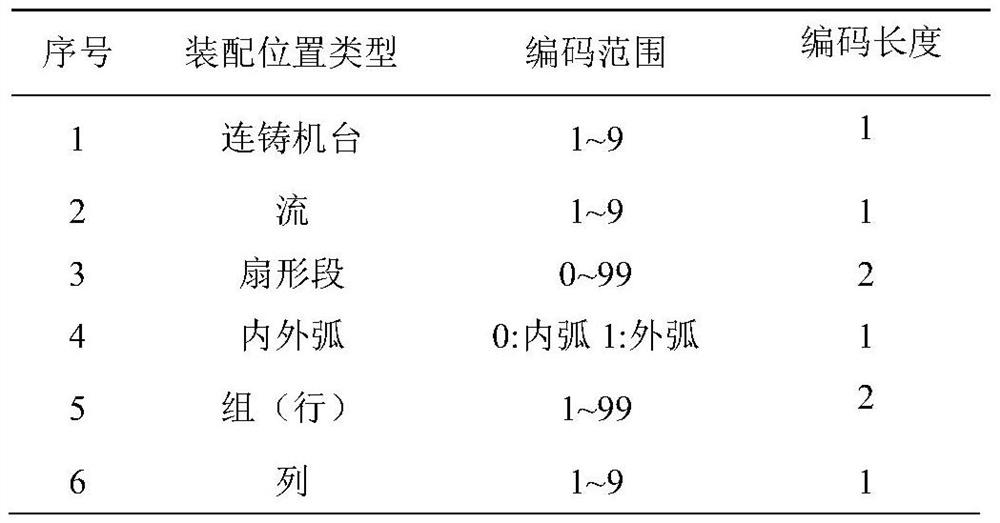

[0044] Step 1: Build the system framework; the system architecture consists of 5 layers: physical layer, transport layer, model layer, data layer and application layer, such as figure 2 . Among them, the 3D twin model of the continuous casting machine is an entity mirroring 3D model of all the elements of the physical equipment of the continuous casting machine. Through the lightweight processing technology of the 3D model, web browsing and display are realized. The twin data is based on the Internet of Things (IoT) technology to realize data collection of the physical equipment information of the continuous casting machine; the physical equipment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com