Liquid crystal writing film local erasing voltage loading control method

A technology of erasing voltage and control method, applied in the direction of electrical digital data processing, instrument, data processing input/output process, etc., can solve the problem of excessive capacitance of liquid crystal writing film, uneven thickness of glue coating, and partial erasure Effect and other issues, to achieve the effect of improving the yield, reducing the quality and the requirements of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

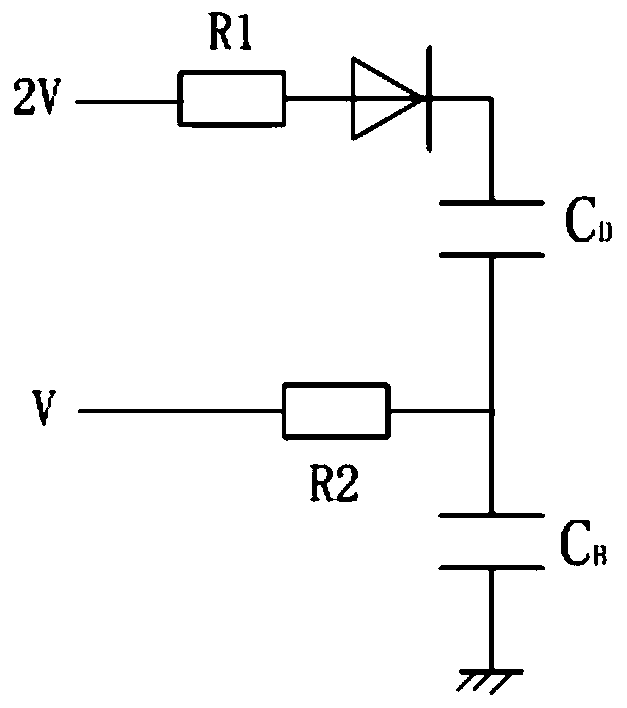

[0055] Based on the above description of the problems in the prior art, the embodiment of the present invention discloses a method for controlling voltage loading for local erasing of a liquid crystal writing film. This embodiment introduces a method for controlling voltage loading during voltage boosting.

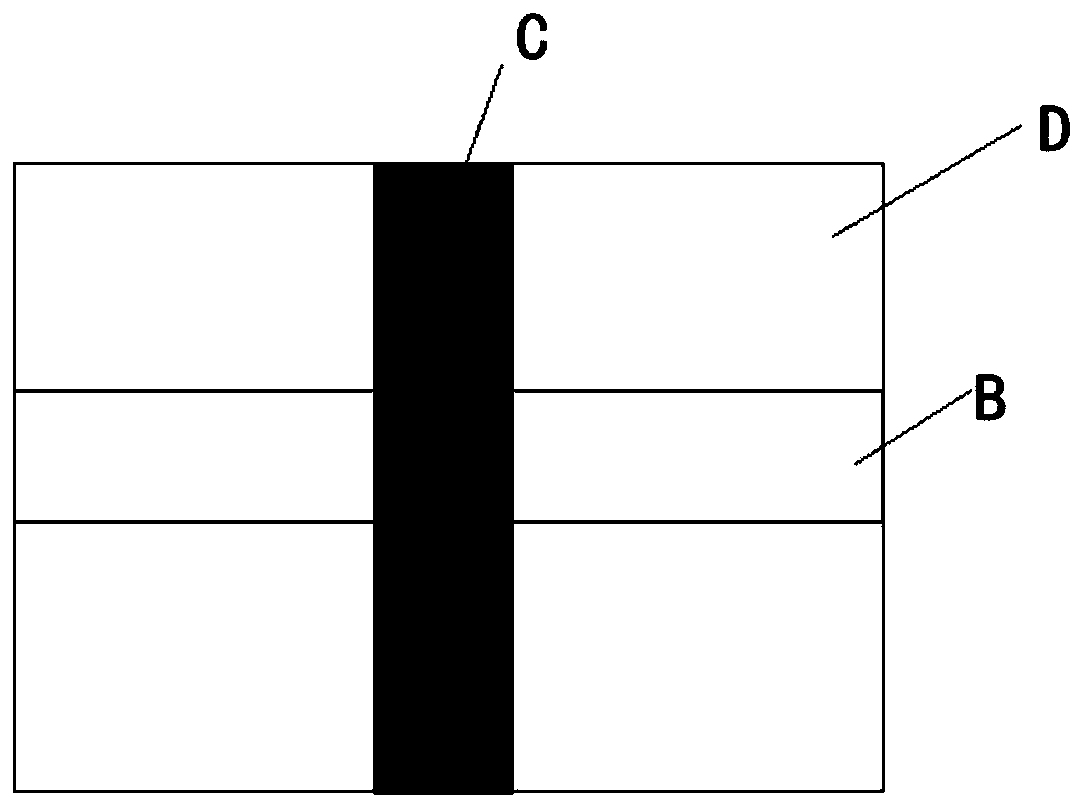

[0056] Wherein, the liquid crystal writing film is located between two conductive layers, and the two conductive layers are respectively divided into two or more than two conductive regions. In this embodiment, the first conductive layer is divided into two or more lateral conductive regions that are insulated from each other, and the second conductive layer is divided into two or more vertical conductive regions that are insulated from each other; The conductive regions on the second conductive layer and the conductive regions on the second conductive layer are vertically interlaced with each other in space. By dividing the conductive layer, the writing film is divided in...

Embodiment 2

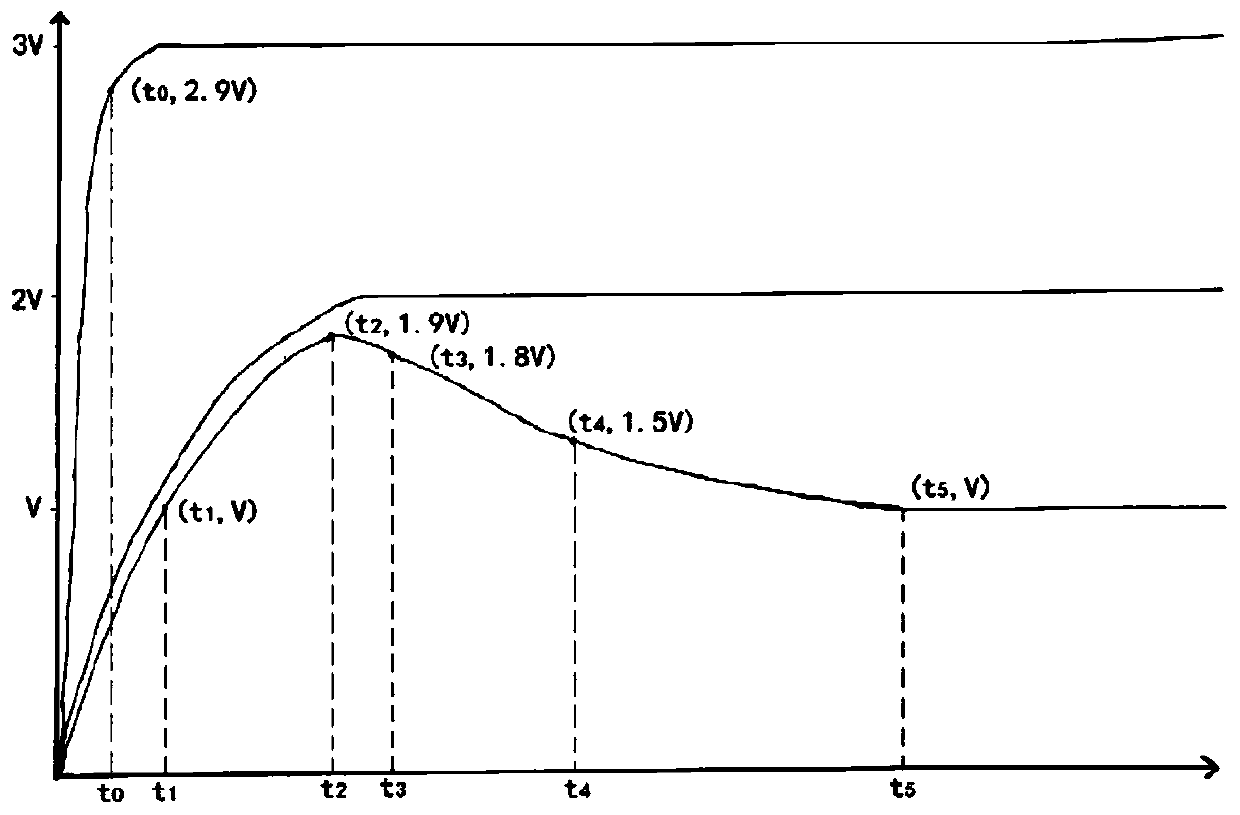

[0087] In some other embodiments, a method for controlling the partial erasing voltage step-down process is disclosed, such as Figure 7 As shown, it specifically includes the following process:

[0088] (1) The voltage of the conductive area covering the partial erasing area on the first conductive layer is reduced from 3Va to Va, so that the absolute value of the voltage difference between each set conductive area on the two conductive layers is Va;

[0089] (2) The voltage of each set conductive area on the second conductive layer is reduced from 2Va to zero, and the absolute value of the voltage difference between each set conductive area on the two conductive layers is still Va;

[0090] (3) The voltage of each set conductive area on the first conductive layer is reduced from Va to zero, and the voltage difference between all set conductive areas on the two conductive layers is zero.

[0091] It can be seen that during the step-by-step step-down process, the voltage diff...

Embodiment 3

[0095] On the basis of Embodiment 1, the embodiment of the present invention discloses a liquid crystal writing film using a local erasing voltage loading control method, and specific application products of the writing film, such as:

[0096]The liquid crystal writing film adopting the local erasing voltage generation and control method of the present invention is applied to a writing board, a drawing board or a blackboard to realize the local erasing function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com