Method for determining content of soluble hydrogen sulfide in desulfurization solution

A method of determination, technology of hydrogen sulfide, applied in the direction of chemical method analysis, measuring device, chemical analysis by titration method, etc., can solve the problems of unsatisfactory reproducibility of results, consumption of iodine solution, high cost, etc., and achieve accurate titration end point, Reduce titration cost and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

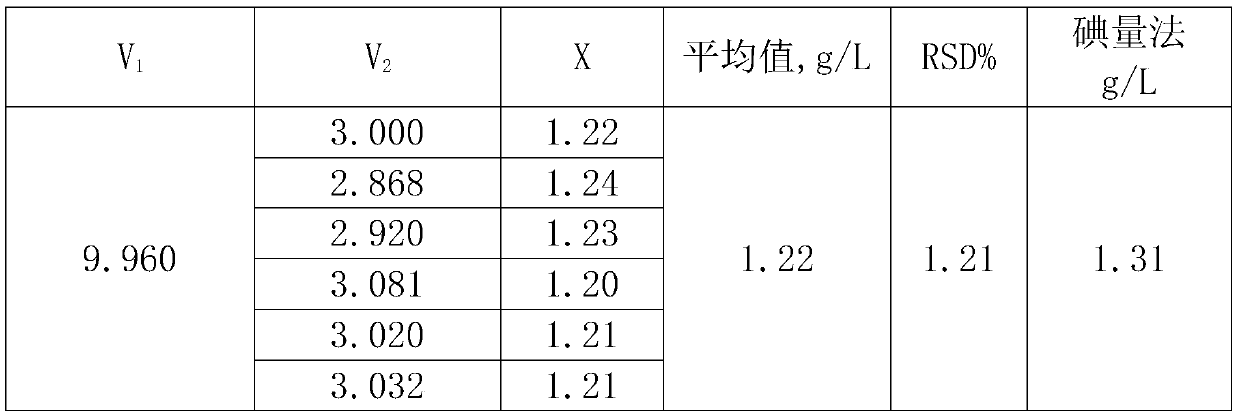

Image

Examples

Embodiment 1

[0052] A method for measuring the content of soluble hydrogen sulfide in a desulfurization solution, wherein the desulfurization solution is divided into a lean amine solution and a rich amine solution, and the redox method is used with an automatic potentiometric titrator for titration, but the lean amine solution and the rich amine solution are respectively Determination of hydrogen sulfide content using two different procedures;

[0053] Iodine solution needs to be used in the determination process. First, weigh 2.54g of analytically pure iodine, then weigh 7g of analytically pure KI, and then add distilled water to the volumetric flask to dilute to 1L.

[0054] The determination process of lean amine solution is:

[0055] a) Sampling and sample preparation: take 2 milliliters of poor amine solution to be tested, add it to a reaction cup filled with 10 milliliters of double-distilled water, and then add 10 milliliters of C (1 / 2I 2 )=0.02mol / L iodine solution, then add 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com