Novel desulfurization system slurry density measuring device

A new type of desulfurization and density measurement technology, which is applied in the determination of specific gravity by measuring pressure difference, can solve the problems of pressure difference fluctuation, non-real-time monitoring, low accuracy and stability, and achieves low maintenance, good stability, The effect of stable measurement conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

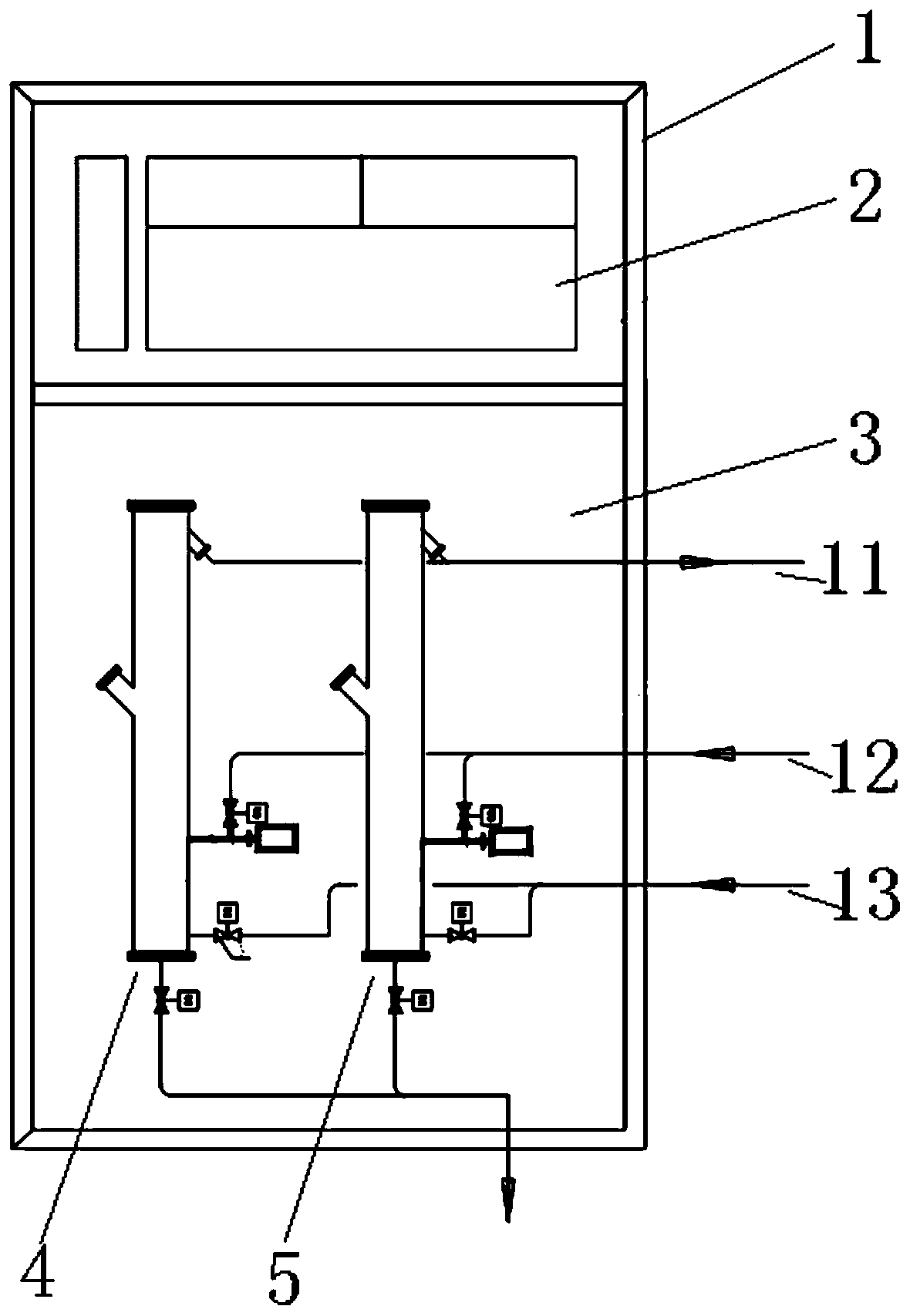

[0022] Such as Figure 1~2 as shown,

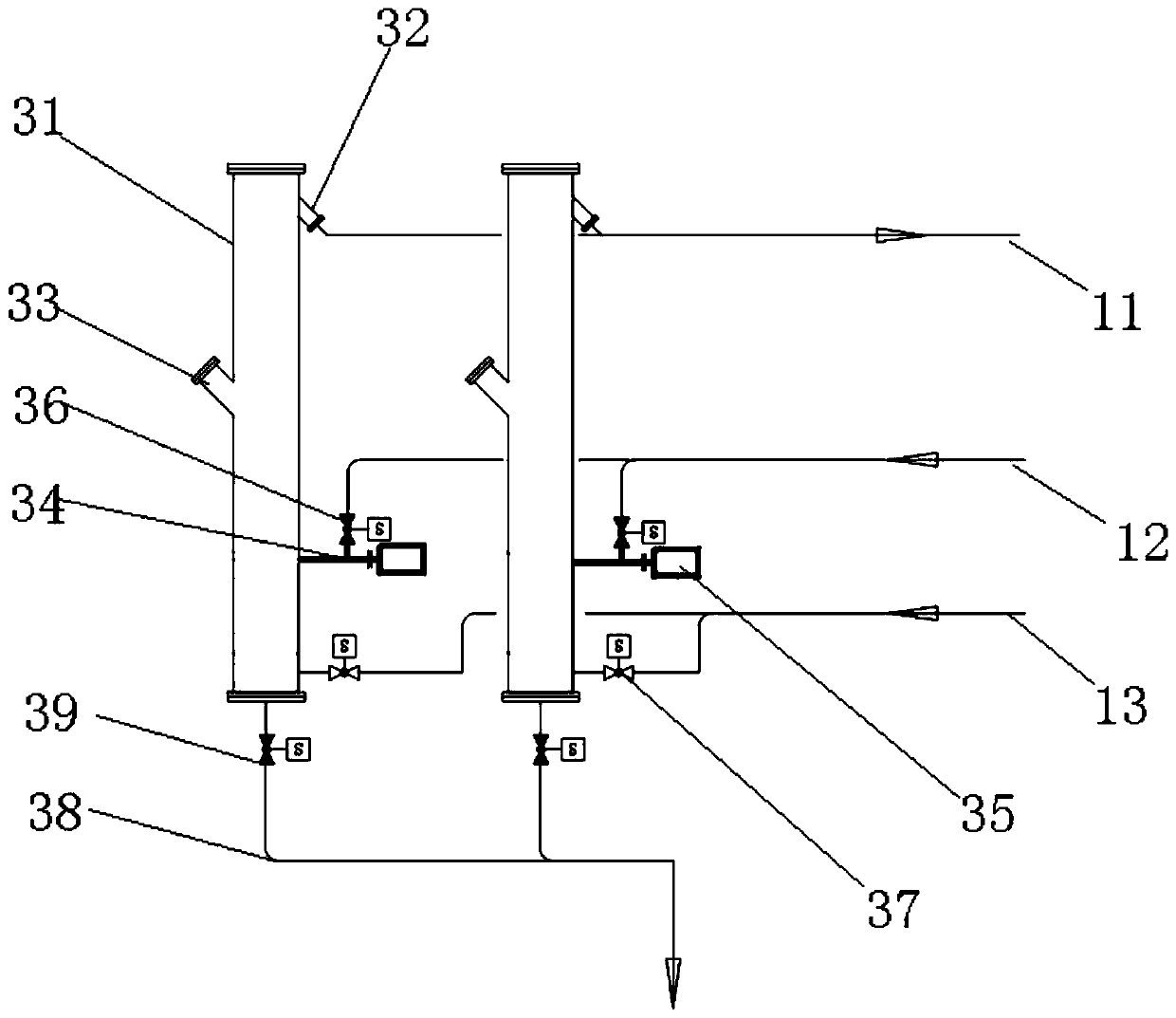

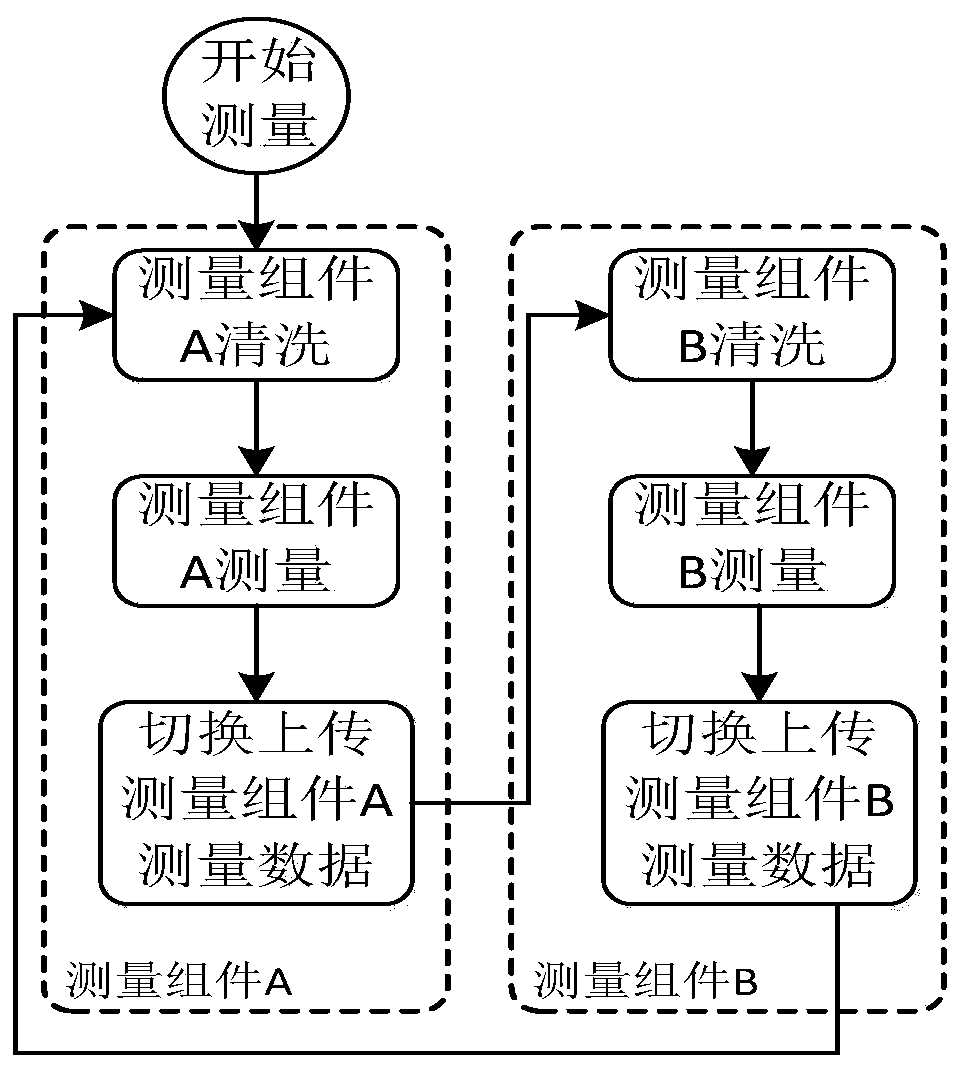

[0023] This embodiment provides a novel desulfurization system slurry density measuring device, including a cabinet 1, an electronic control unit 2 and a measuring unit 3 installed in the cabinet 1, and the measuring unit 3 includes two sets of redundant measuring components and connection measurement The connecting pipe fittings of the assembly, the two sets of measuring assemblies are the measuring assembly A4 and the measuring assembly B5 with the same structure; An overflow port 32, a pH meter interface 33, a measurement opening, a slurry introduction opening and a drainage pipe opening are provided; the overflow port 32 is located on the upper side of the measuring cylinder 31, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com