Low dew point compound dehumidifier

A dehumidifier, low dew point technology, applied in mechanical equipment, heating methods, lighting and heating equipment, etc., can solve the problems of difficult, low dew point dehumidification and high efficiency dehumidification of dehumidifiers, and achieve the effect of regeneration and low air humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

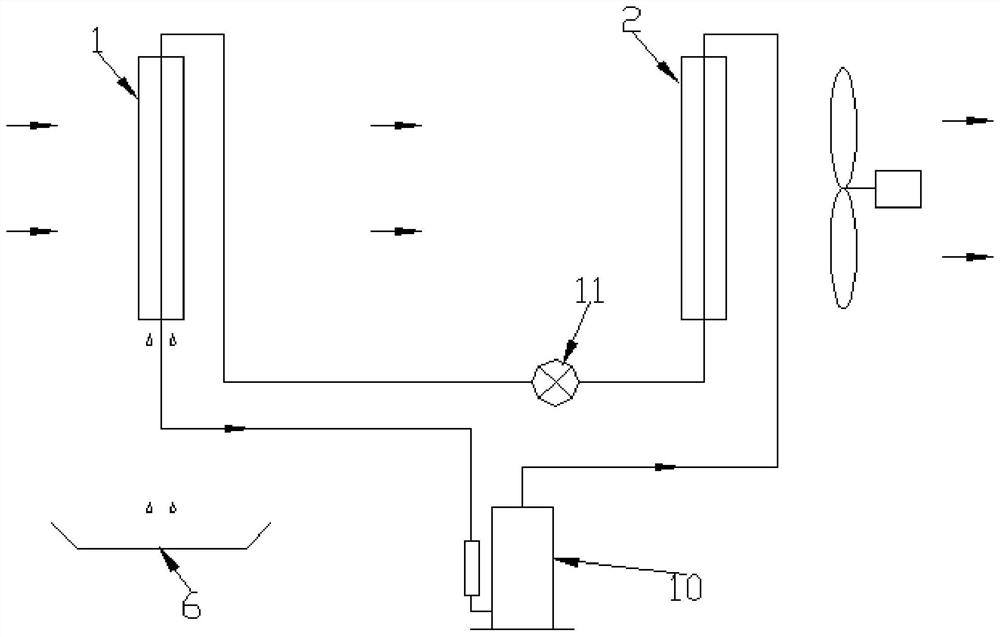

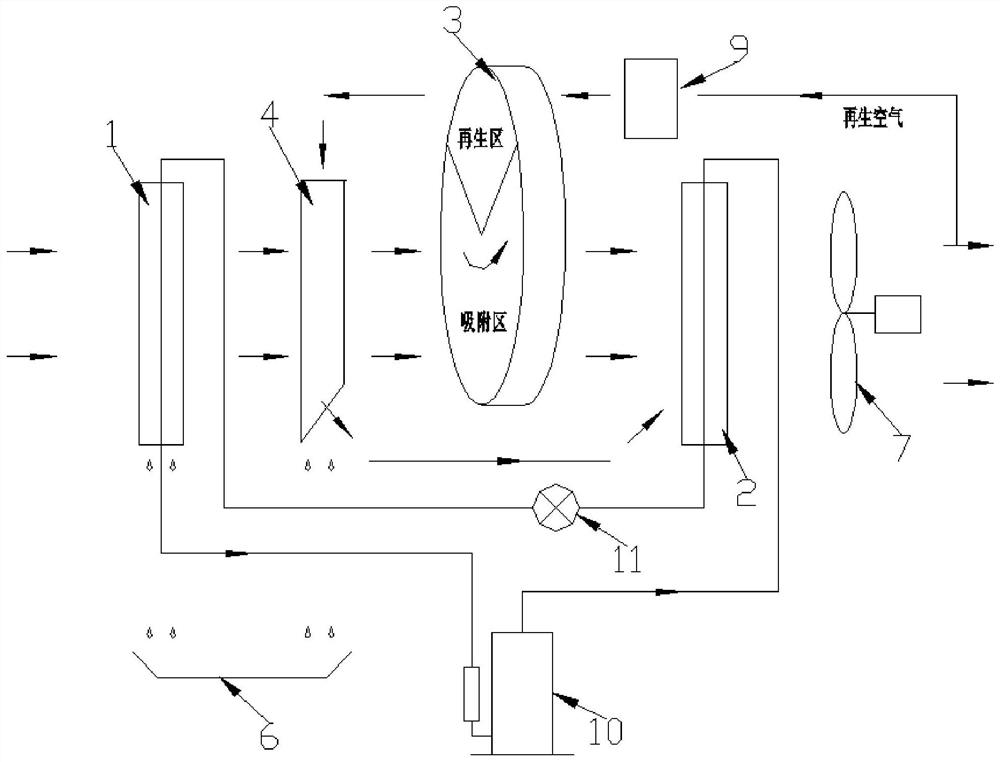

[0034] see image 3 , a low dew point composite dehumidifier, including a dehumidification air channel and a regeneration air channel, wherein the dehumidification air channel is provided with a rotary dehumidification mechanism and a compression refrigeration mechanism, the compression refrigeration mechanism includes an evaporator 1 and a condenser 2, and the rotary dehumidification mechanism Including the dehumidification wheel 3 and the first heat exchanger 4, the air on the dehumidification air duct can pass through the evaporator 1, the first heat exchanger 4, the adsorption area on the dehumidification wheel 3 and the condenser 2 in sequence, and then flow to the atmosphere; after condensation Part of the airflow of the device 2 flows to the condenser 2 after passing through the heater 9, the regeneration zone on the dehumidification wheel 3, and the first heat exchanger 4, and the first fan 7 is located on the air outlet side of the condenser 2.

Embodiment 2

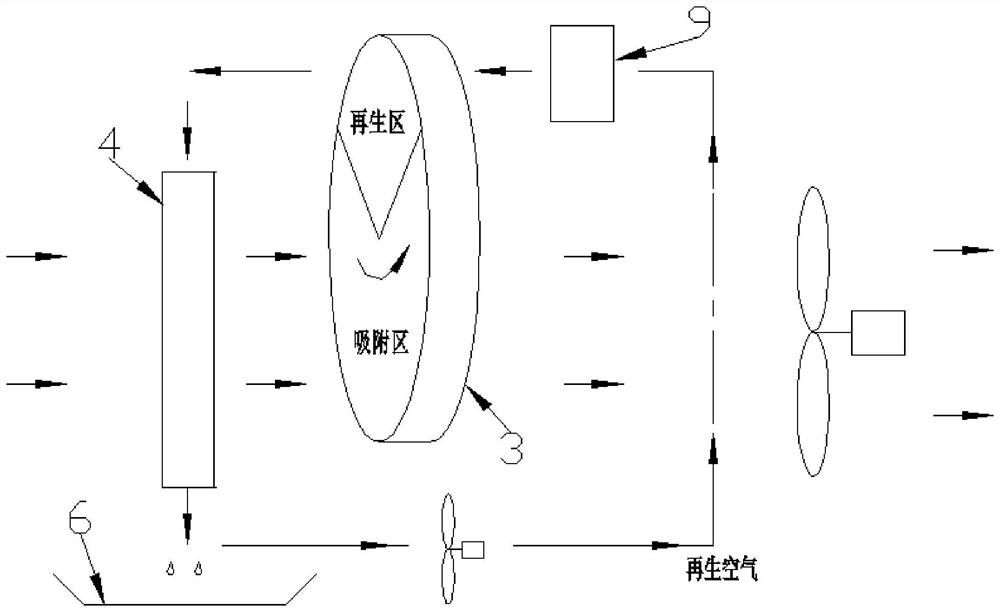

[0036] see Figure 4, a low dew point composite dehumidifier, the difference from Example 1 is that the regeneration air duct is provided with a second heat exchanger 5 for reducing the temperature of the air on the regeneration air duct, and the air passing through the regeneration area of the dehumidification wheel passes through the second heat exchange After the device 5, it flows to the first heat exchanger 4, and the second heat exchanger 5 is used in conjunction with the pre-cooling fan 12.

Embodiment 3

[0038] see Figure 5 , a low dew point composite dehumidifier, the difference from Example 2 is that a second fan 8 is provided on the regeneration air duct, and part of the air flow passing through the condenser 2 flows to the heater 9 through the second fan 8 .

[0039] see Figure 5 , the air passes through the evaporator 1 to cool and condense (first-stage dehumidification), and becomes low-temperature air. The adsorption material in the adsorption area of the wheel absorbs the water (second stage dehumidification), and then the air enters the condenser 2 to be heated, and after passing through the first fan 7, the air with high temperature and high pressure is blown out; at the same time, a part of the blown air is drawn The air returns as regeneration air, and after being further heated by the heater 9, it enters the regeneration zone of the dehumidification rotor 3, and the moisture absorbed by the dehumidification rotor 3 is taken away to form high-temperature and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com