Transformer oil chromatogram gas cylinder automatic switching system and switching method thereof

A transformer oil, automatic switching technology, applied in the field of electric power, can solve the problems that maintenance personnel cannot obtain alarm information in real time, prompt alarm information cannot be uploaded, and affect the online rate of oil chromatography, so as to improve the reliability of power supply and the level of automation and reduce data. The effect of drop rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

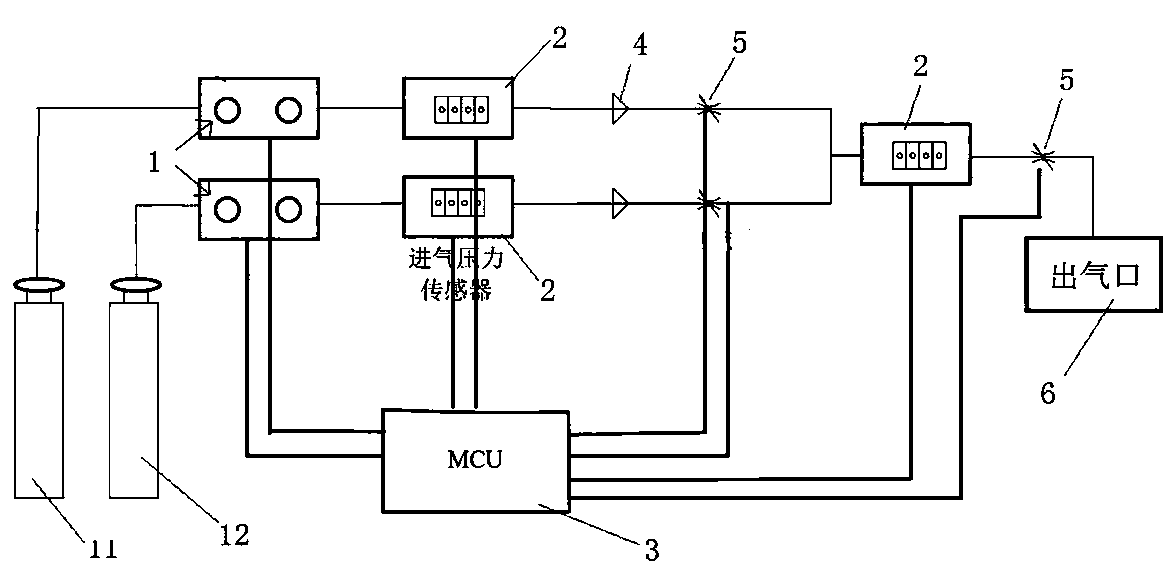

[0022] The present invention will be further explained below in conjunction with the accompanying drawings.

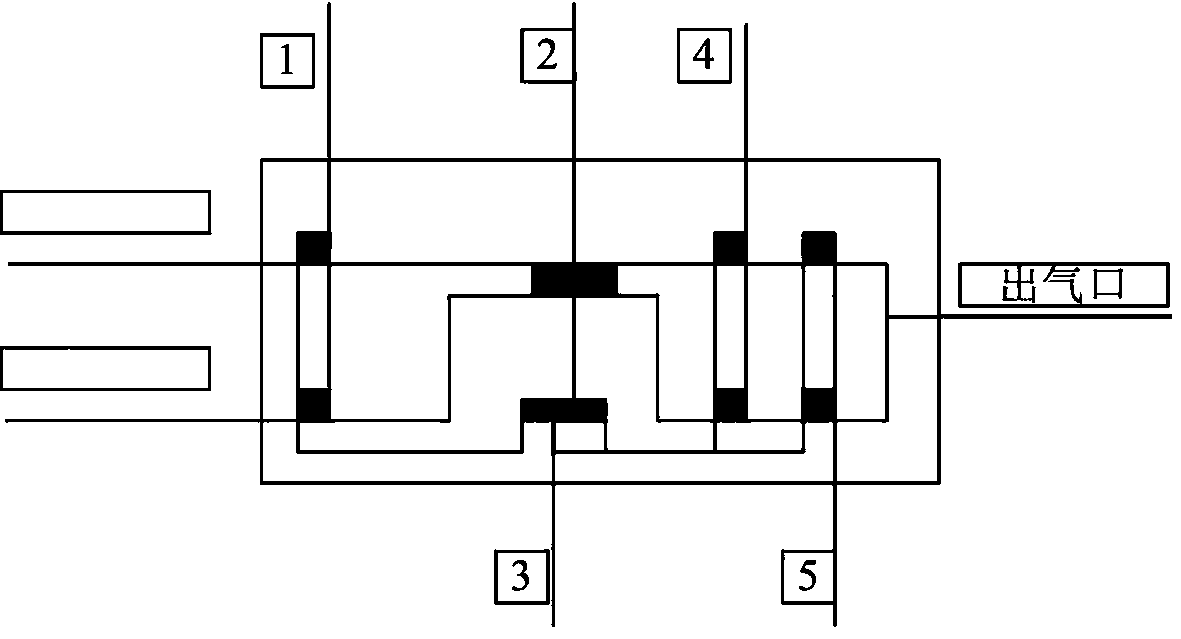

[0023] A transformer oil chromatographic gas cylinder automatic switching system, comprising at least two gas cylinders 11, 12, a control device and a gas outlet 6, the valve controllers of each of the gas cylinders 11, 12 are respectively connected to the input port of the control device, the The air outlet 6 is connected to the output port of the control device; data can be transmitted between the control device and the PMS.

[0024] The above gas cylinder automatic switching system, the control device includes a single chip microcomputer 3 and pipelines connected to the gas cylinders one by one, the pipelines are distributed in parallel, and the pipelines are provided with a pressure reducing valve 1 and a pressure sensor 2 , check valve 1 and electromagnetic valve 5, described decompression valve 1 and pressure sensor 2 are the input signals of single-chip microcom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com