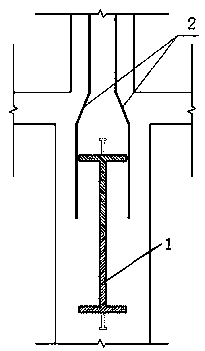

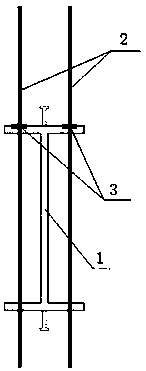

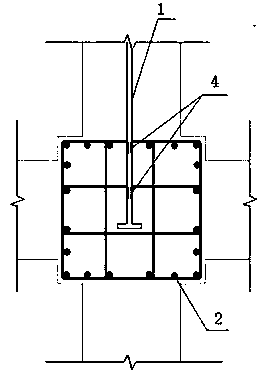

Construction process of H-shaped steel concrete transfer beam-reinforced concrete column joint

A reinforced concrete column and construction technology technology, applied in the direction of architecture, building structure, etc., can solve problems such as few research results, and achieve the effect of meeting structural design requirements, simplifying construction technology, and reducing steel binding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The construction technology of the H-shaped steel concrete transfer beam-reinforced concrete column node of the present embodiment, the construction technology comprises the following steps:

[0045] Step 1: Deepening design of joints: apply CAD three-dimensional modeling technology to the H-shaped steel concrete transfer beam-reinforced concrete column connection structure design drawing, deepen the design of the H-shaped steel concrete transfer beam-reinforced concrete column joint diagram, and check the arrangement of steel bars at the joints and the H Precise positioning is required for the profiled steel webs and flanges, including:

[0046] (1) Draw the detailed drawing of the steel frame of the steel beam;

[0047] (2) Draw detailed cross-section drawings of steel concrete beams, and optimize the positioning and arrangement of medium steel, longitudinal steel bars and stirrups of steel concrete beams;

[0048] (3) Draw the details of the joint where the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com