Construction method of pressurized cast-in-place pile based on reinforced fibers and metakaolin

A construction method and fiber-reinforced technology, which can be applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of mud pollution in construction engineering, low quality of poured piles, and complicated process, so as to reduce temporary land use and increase bearing capacity , high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

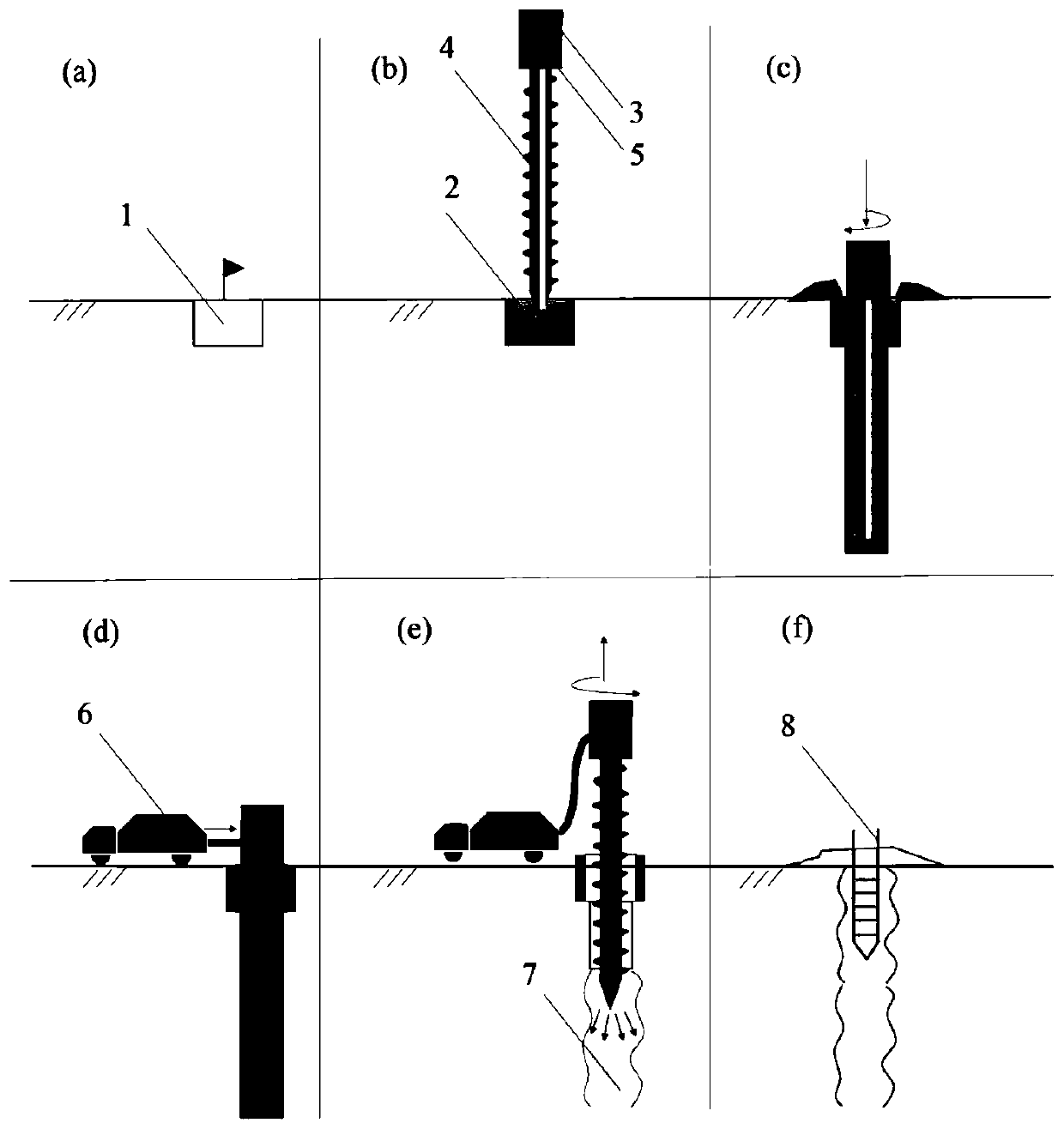

[0023] Using fiber reinforced materials and natural mineral metakaolin to improve the tensile performance and ductility of concrete, combined with the construction method of bored and pressurized cast-in-place piles, excavation of foundation pit 1 on the surface, removal of surface construction waste and coarse-grained soil, through steel The protective tube 2, to ensure the quality of the concrete construction at the top of the pile, the hollow drill pipe 4 is driven by the power device 3, and the hollow drill pipe 4 is rotated in the foundation soil to the design elevation of the designed pile bottom, and then the hollow drill pipe 4 is rotated in the reverse direction. The composite concrete material with added fiber and metakaolin is poured into the cavity 5 and the hollow drill rod 4 through the pressure of the ground pump 6 to form the pile body 7, and finally the embedded steel bars 8 are inserted. Such as figure 1 As shown, the specific process is as follows:

[0024] a....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com