Electroplating environment treatment device for electroplating outside the cylinder tank

A technology for processing devices and environments, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of production line shutdown, different fixtures, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

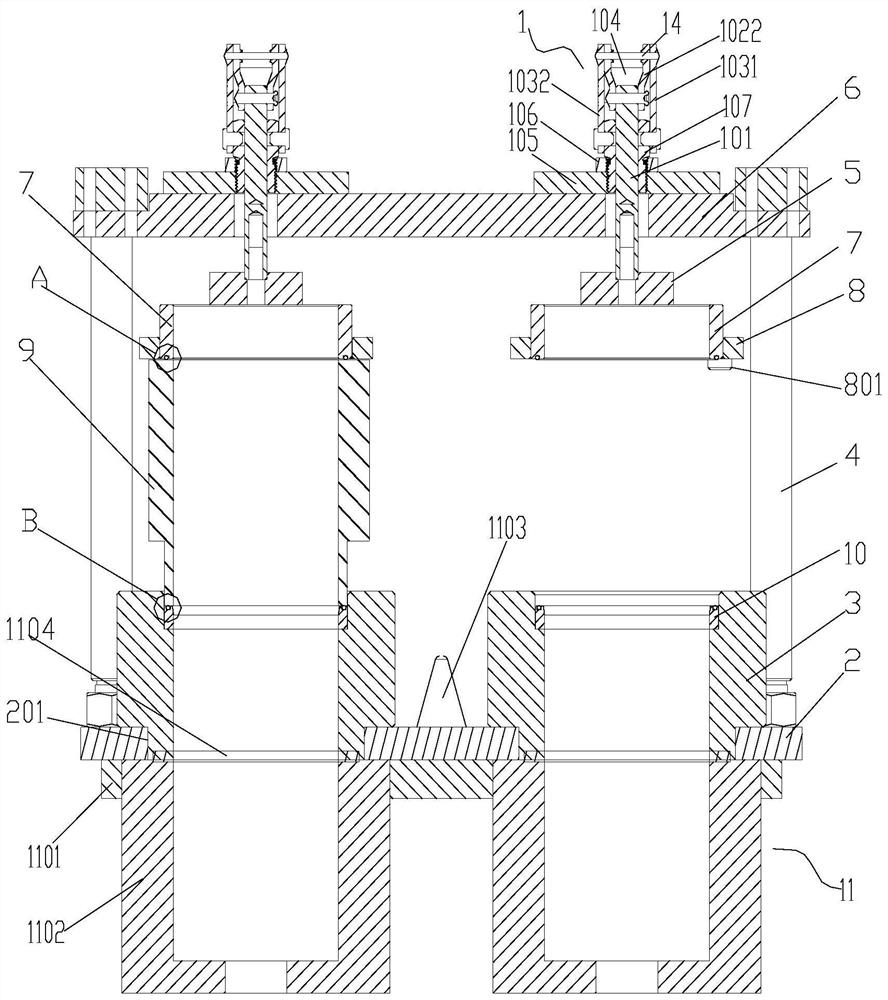

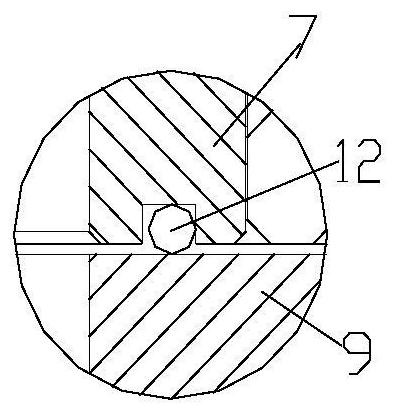

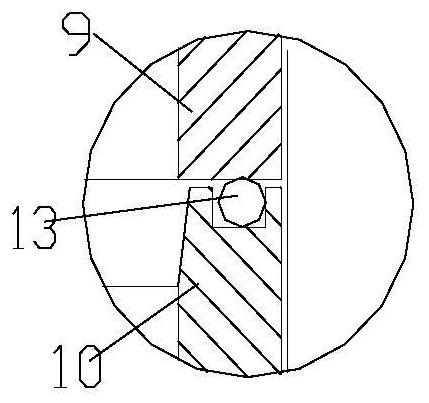

[0040] figure 1 It is a structural sectional view of the present invention, figure 2 for figure 1 Enlarged view at A, image 3 for figure 1 Enlarged view at B, image 3 It is a three-dimensional view of the present invention (installed on the device), as shown in the figure: the electroplating environment treatment device for electroplating outside the cylinder tank of this embodiment includes a mounting frame assembly, an installation auxiliary assembly and a diversion installation assembly 11, including installation A frame assembly and an installation auxiliary assembly, the installation frame assembly includes a fixing frame and a pressing assembly 1;

[0041] The fixed frame includes a base plate 2 and a frame fixed on the base plate;

[0042] The installation auxiliary assembly is used to install the workpiece and after compensation in height and diameter, it is installed on the bottom plate and pressed by the pressing assembly 1, and the installation auxiliary ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com