Preparation method of epoxidized soybean oil derivative

A technology for epoxidized soybean oil and derivatives, which is applied in the field of preparation of epoxidized soybean oil derivatives, can solve the problems of high odor, low plasticization efficiency of epoxidized soybean oil, etc., achieves light color, simple and efficient preparation method, and volatile low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

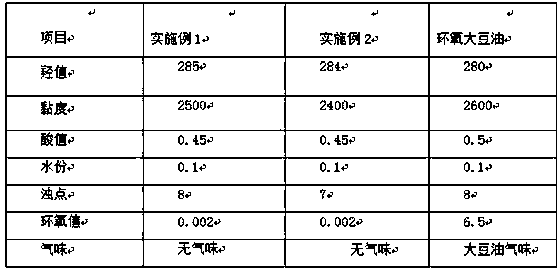

Examples

Embodiment 1

[0019] A preparation method of epoxidized soybean oil derivatives is characterized in that the preparation method is: in an autoclave, add epoxidized soybean oil, anhydrous methanol, solvent, water and a catalyst, and evacuate with nitrogen at 2°C / The heating rate is 1 min, the temperature is raised to 100°C, the reaction pressure is self-generated pressure, the reaction is 12h, the solvent is evaporated, and the unreacted catalyst is washed with saturated sodium sulfate solution to completely remove the unreacted catalyst, and the water is removed by rotary evaporation under reduced pressure. ;

[0020] Wherein the weight ratio of each component is: epoxidized soybean oil: anhydrous methanol=10: 13;

[0021] Epoxidized soybean oil: solvent=10:11;

[0022] Epoxidized soybean oil: water=10:2;

[0023] Epoxidized soybean oil:catalyst=10:0.2.

[0024] As a further solution of the invention: the solvent is n-hexane, isopropanol, and dimethyl sulfoxide.

[0025] As a further s...

Embodiment 2

[0028] In the embodiment of the present invention, the difference from embodiment 1 lies in the difference in the weight parts of raw materials, and other conditions are the same.

[0029] A preparation method of epoxidized soybean oil derivatives is characterized in that the preparation method is: in an autoclave, add epoxidized soybean oil, anhydrous methanol, solvent, water and a catalyst, and vacuumize with nitrogen at 10 ° C / The heating rate is 1 min, the temperature is raised to 160°C, the reaction pressure is autogenous pressure, the reaction is 20h, the solvent is evaporated, and the saturated sodium sulfate solution is washed to completely remove the unreacted catalyst, and then the water is removed by rotary evaporation under reduced pressure, and the suction is filtered under reduced pressure ;

[0030] Wherein the weight ratio of each component is: epoxidized soybean oil: anhydrous methanol=10: 14;

[0031] Epoxidized soybean oil: solvent=10:13;

[0032] Epoxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com