Hydraulic lifting cargo elevator

A technology of hydraulic lifting and freight elevator, applied in the direction of lifting frame, lifting device, etc., can solve the problems of no-load waste, inability to protect high-rise goods, cumbersome and other problems, and achieve reasonable carrying capacity, avoid overload risks, and eliminate no-load waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

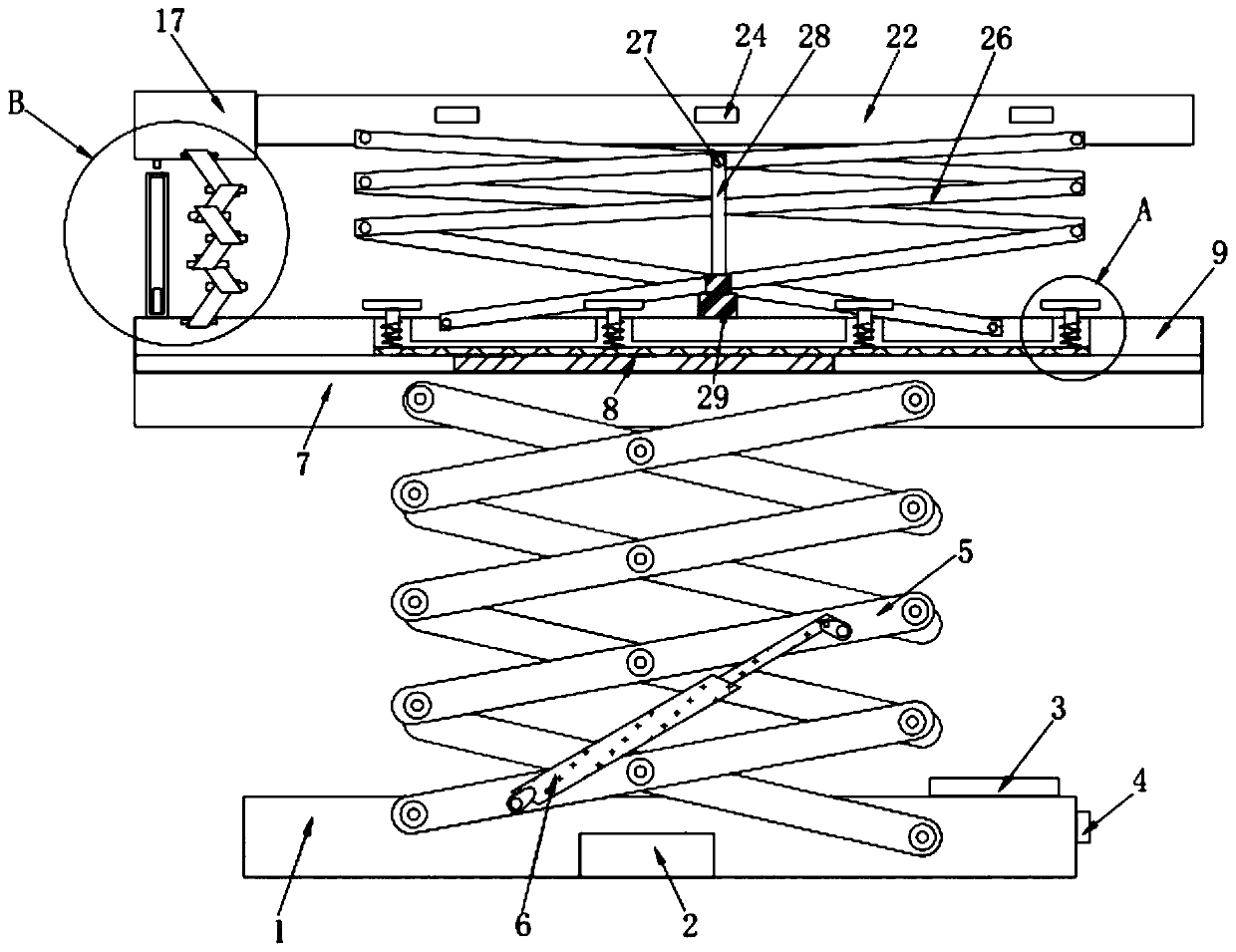

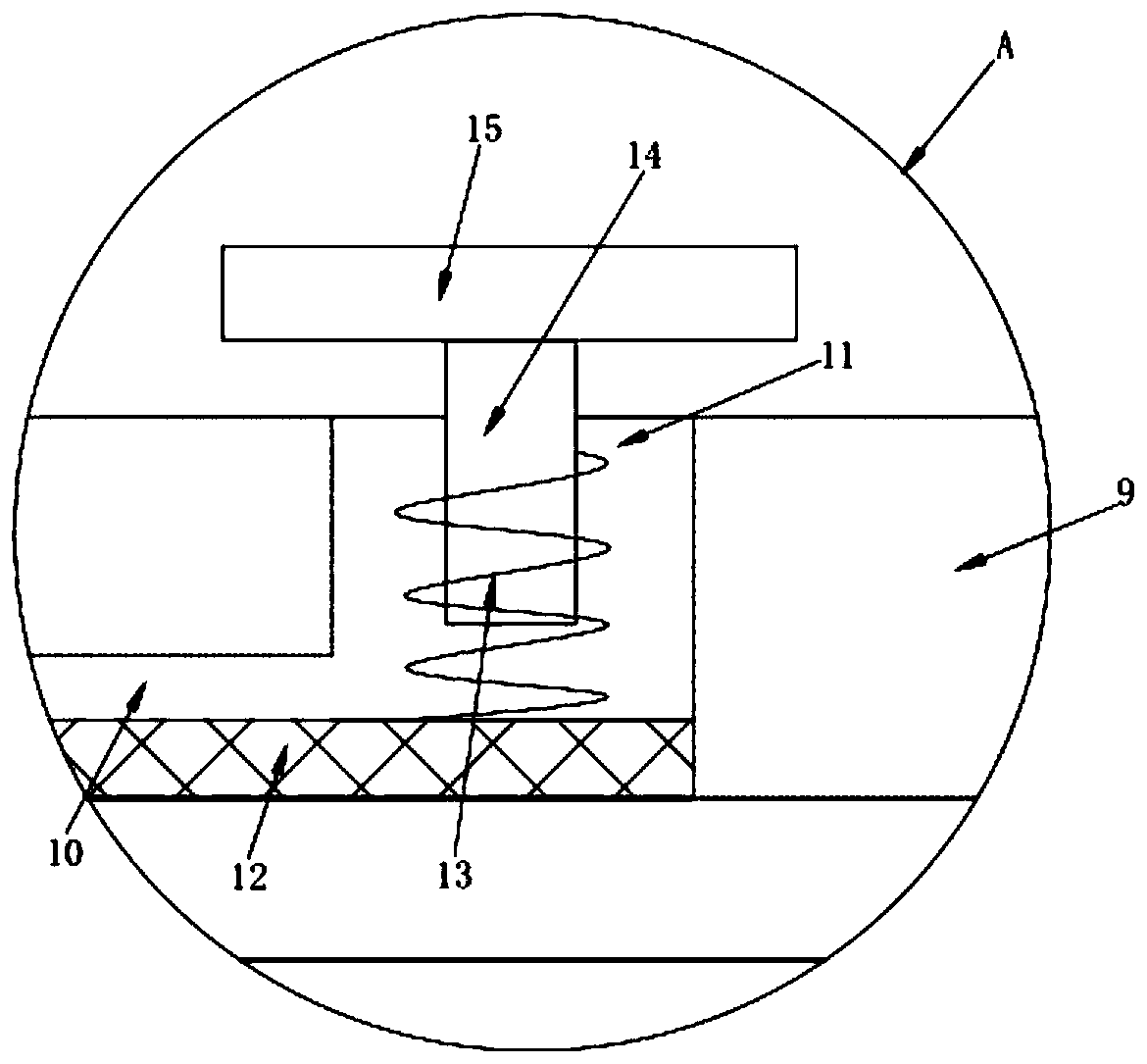

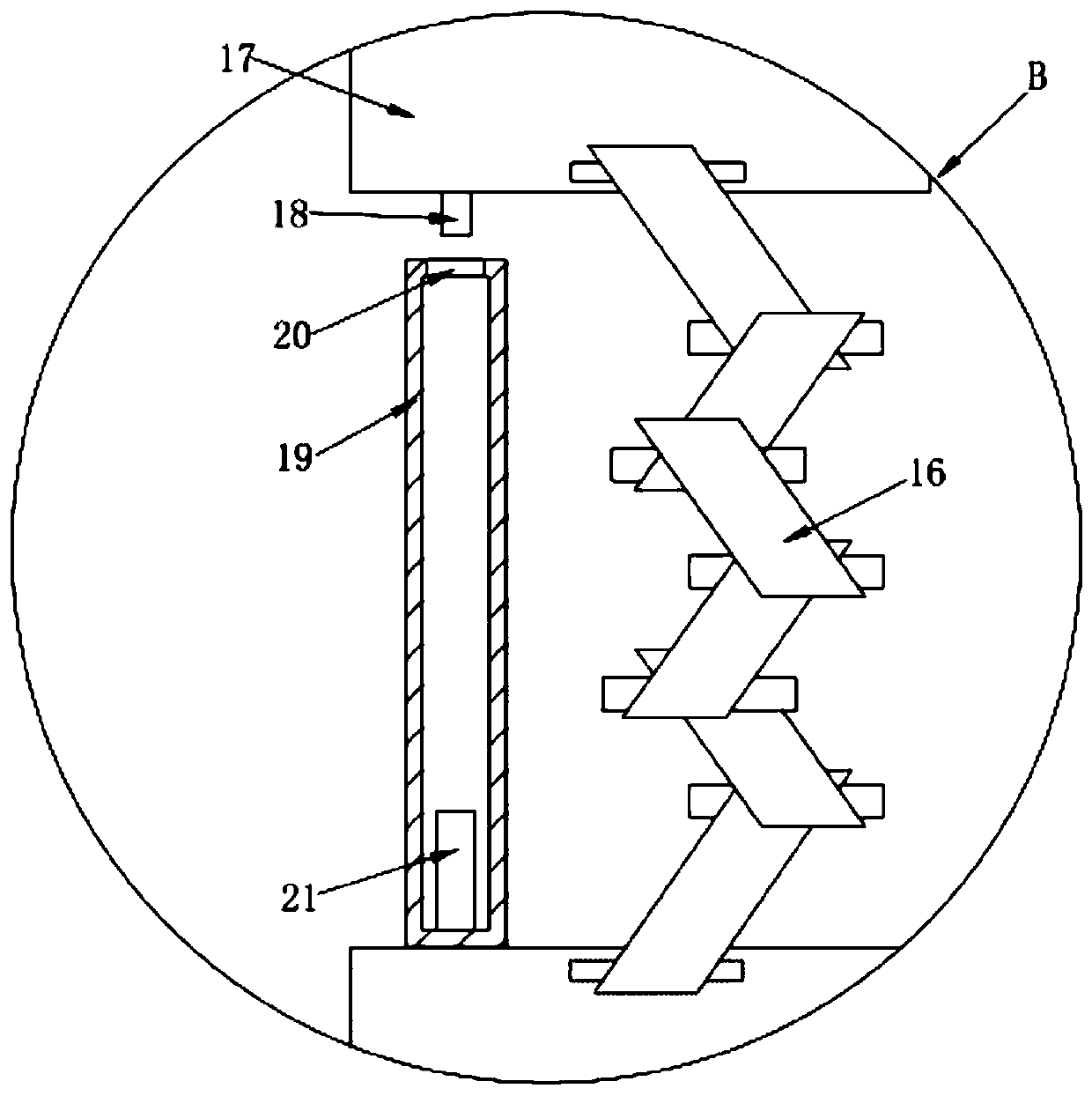

[0023] See Figure 1-4 , The present invention provides a technical solution:

[0024] A hydraulic lift freight elevator includes a base 1, and a PLC controller 2 is arranged in the inner cavity of the base 1. The PLC controller 2 can adopt the FX1N-40MR-001 model provided by Mitsubishi brand. The surface of the base 1 is provided with a display board 3. The display board 3 is used to display the height and weight information of the goods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com