Automatic coating machine

A film sticking machine and film sticking technology, applied in packaging and other directions, can solve the problems of air bubbles left on the surface of the protective film and the product, poor reliability, and difficult to guarantee position accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

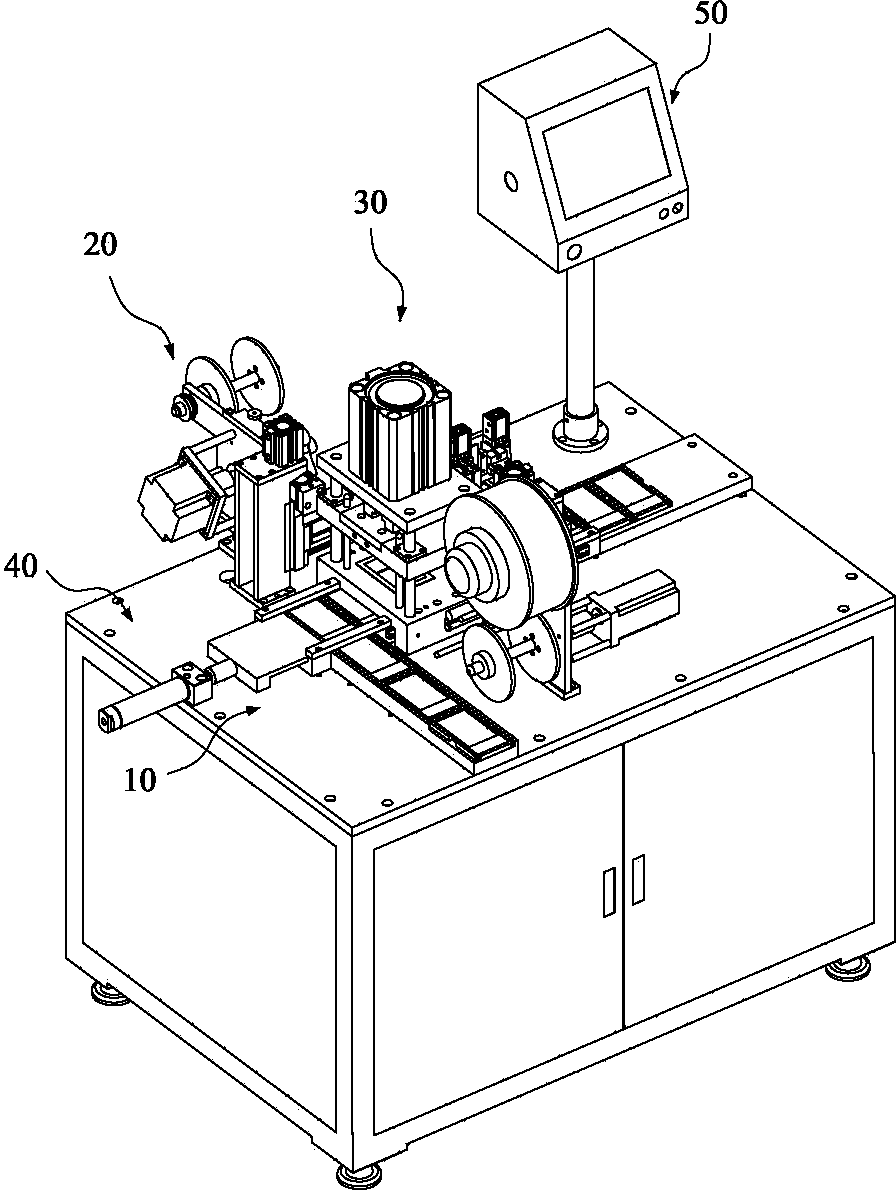

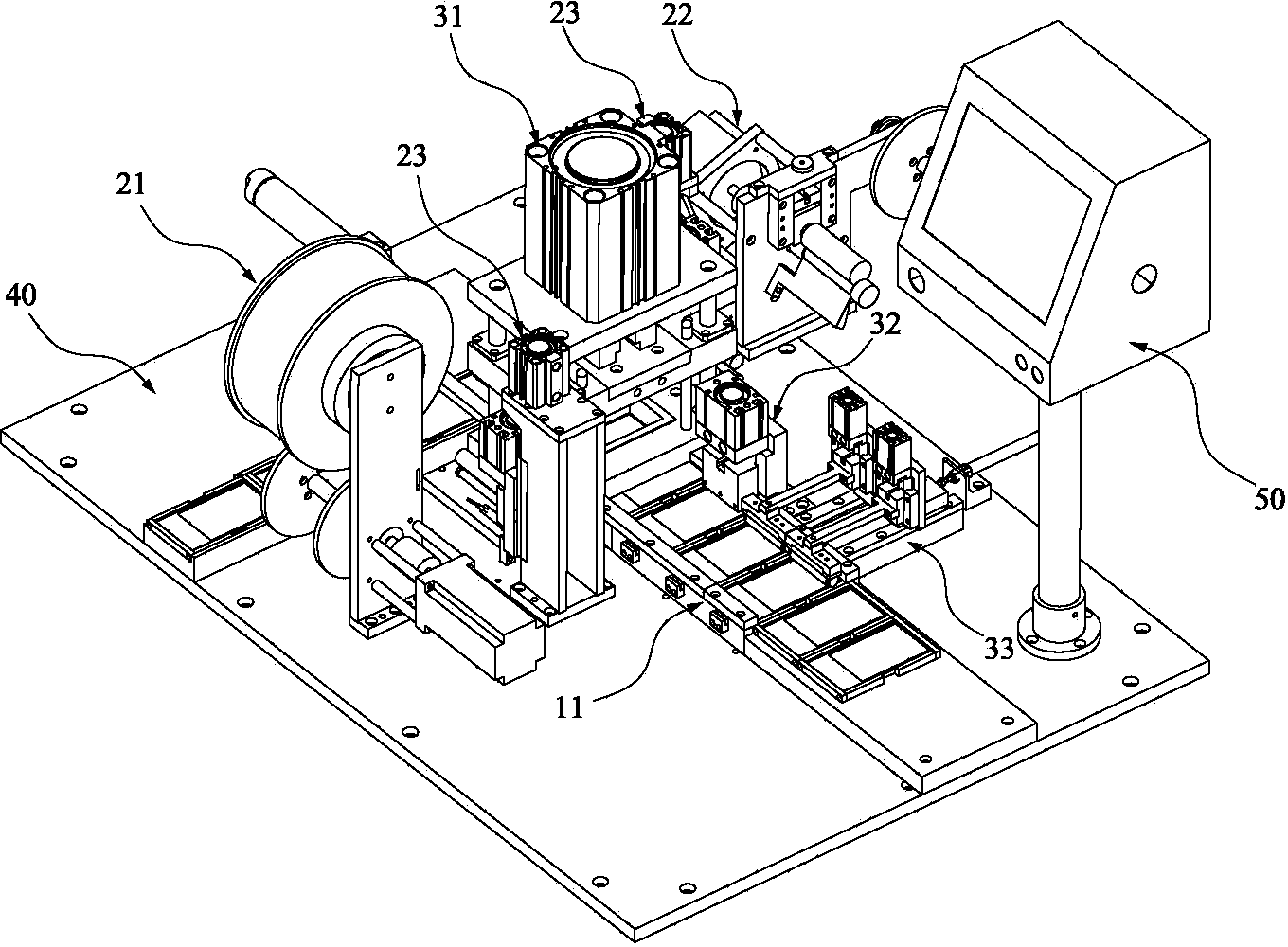

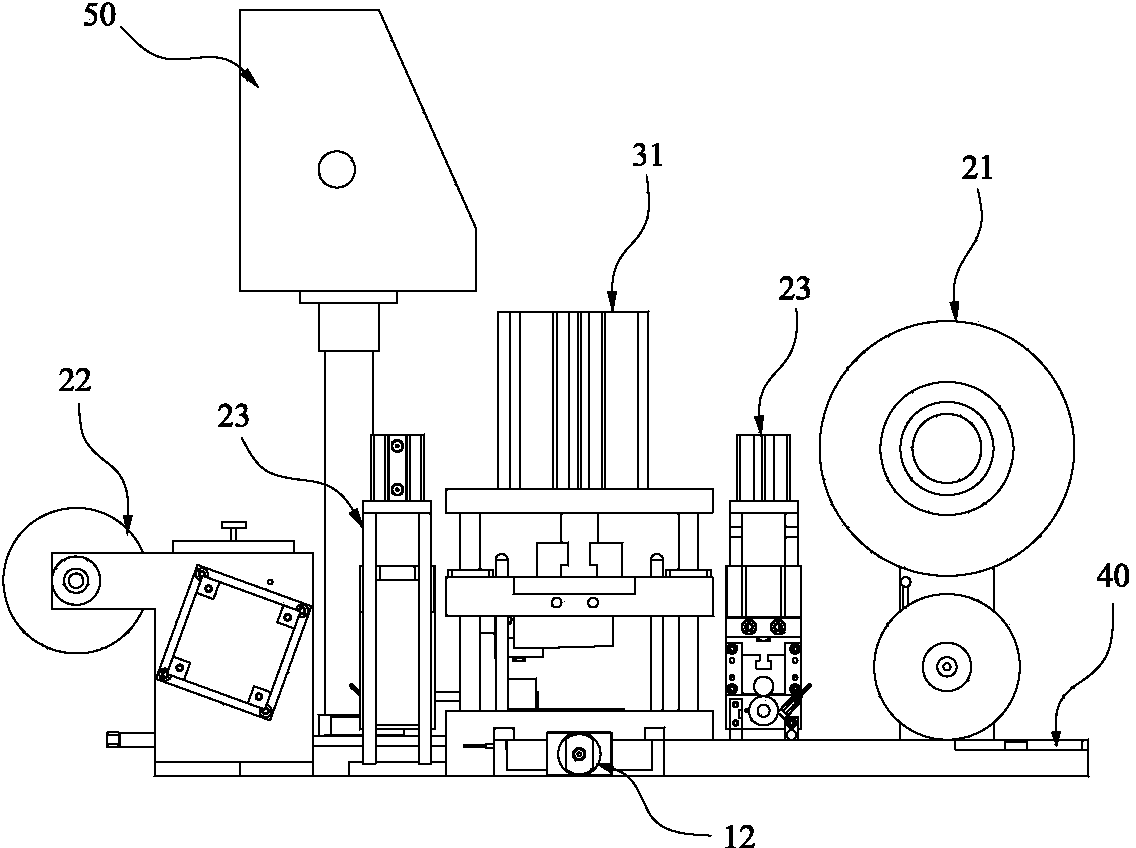

[0073] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a working platform 40 and a product conveying system 10 , a protective film conveying and recycling system 20 , and a film sticking system 30 arranged on the working platform 40 . The protective film conveying and recycling system 20 includes two parts: tape conveying and protective film residue recycling. When the machine is running, the product conveying system 10 automatically sends the product to the film sticking station 113, and at the same time the protective film is automatically sent to the film sticking station 113, and the film sticking system 30 punches out the protective film and sticks it on the surface of the product. After the film sticking action is completed , the product is automatically sent out, and the remaining material after punching the protective film is automatically recovered.

[0074] Among them, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com