Stacking device for power equipment

A technology for power equipment and mobile devices, applied to cranes, etc., can solve problems such as high requirements for operating space, safety of power equipment damage, and large manpower consumption, so as to achieve low requirements for operating space, reduce workload, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

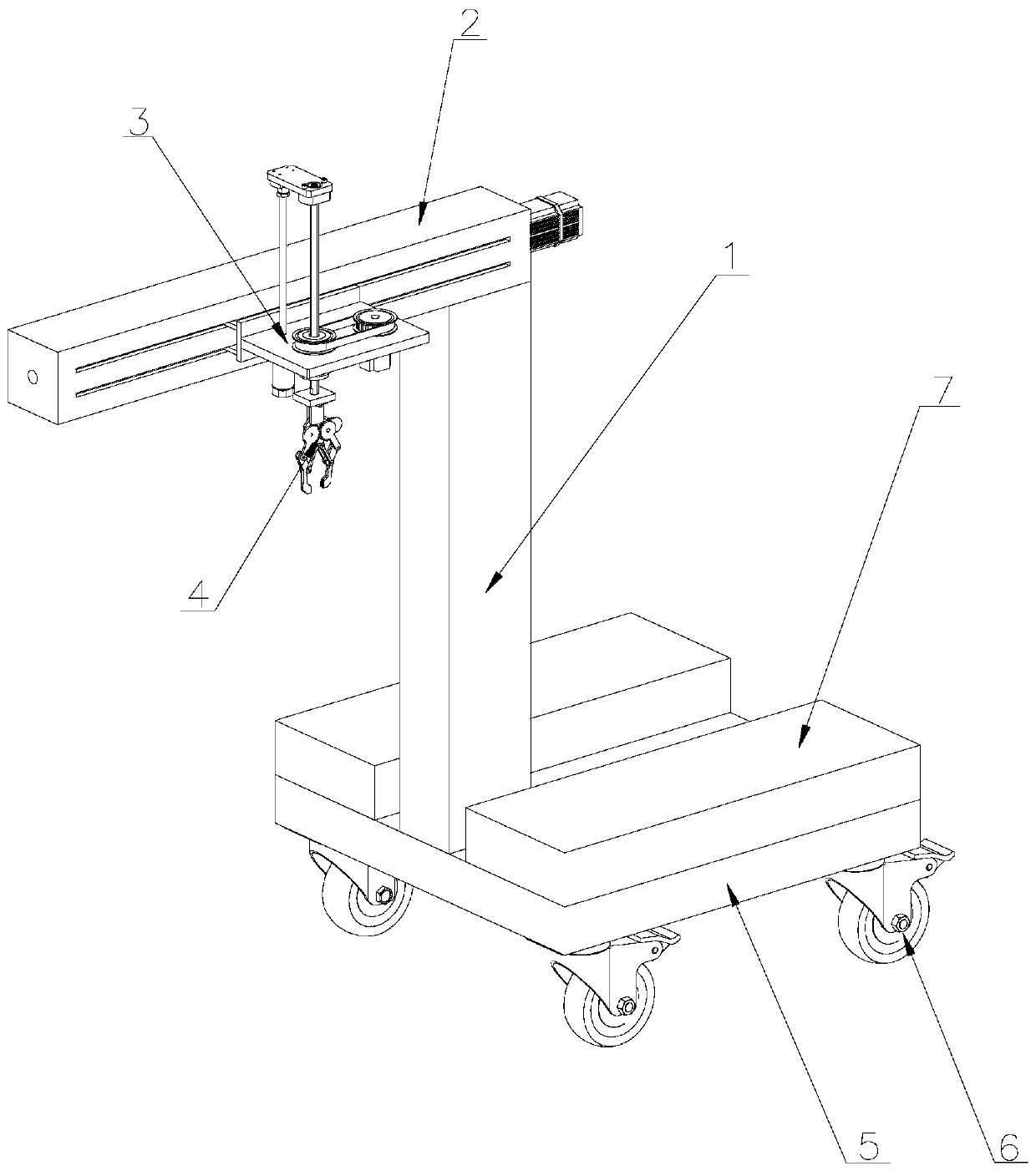

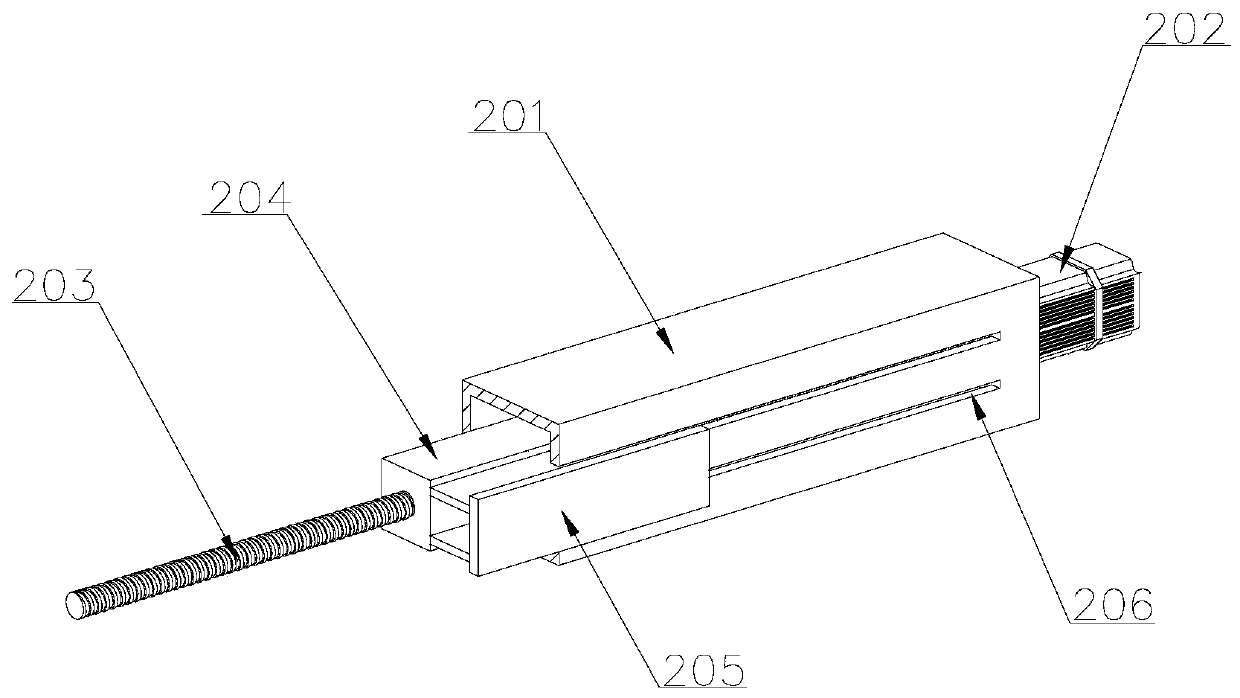

[0031] Such as Figure 1-6As shown, a stacking device for power equipment includes a column 1, a moving device 2, a lifting and rotating device 3, and a clamping device 4. The moving device 2 is arranged on the top of the column 1, and the lifting and rotating device 3 is set On one side of the mobile device 2 and connected with the mobile device 2, the clamping device 4 is arranged at the lower end of the lifting and rotating device 3, and the bottom of the column 1 is provided with a base 5, and the contact area with the ground is increased through the base 5, The stability during work is improved. The base 5 is provided with a counterweight 7 to prevent rollover when the power equipment is heavy and ensure the stability during work. The bottom of the base 5 is provided with a walking wheel 6, It is convenient for the device to move and improves the efficiency of the movement. When stacking the power equipment, the power equipment is clamped and fixed by the clamping device ...

Embodiment 2

[0036] Such as Figure 7 As shown, the difference from Embodiment 1 is that the clamping device 4 includes a top plate 411, a vertical plate 412, a first splint 413, a second electric telescopic rod 414, a third electric telescopic rod 415, and a second splint 416. The top plate 411 is fixed on the bottom of the slide bar 308, the vertical plate 412 is fixed on both sides of the top plate 411, the first splint 413 is set on the inner side of the vertical plate 412, and the second electric telescopic rod 414 is set on the Between the vertical plate 412 and the first splint 413, the second electric telescopic rod 414 is installed on the vertical plate 412, and the movable end of the second electric telescopic rod 414 is connected with the first splint 413, and the third electric telescopic rod 415 is arranged on the first splint 413. The top and the bottom of a splint 413, the second splint 416 is set with the movable end of the third electric telescopic rod 415, and the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com