Method for preventing wood boards from deforming

An anti-deformation, plank technology, which is applied in the jointing of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve problems such as distortion, slow water loss on the recessed surface of annual rings, and furniture deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of plank anti-deformation method of the present invention comprises the following steps:

[0022] 1) Cutting:

[0023] Cut the wood that has just been felled into sections of the required length, cut the wood at the center of the annual rings of the wood, and cut the two semicircular woods into planks with equal thickness. Make neat planks of required thickness and width for use;

[0024] 2) Selection board:

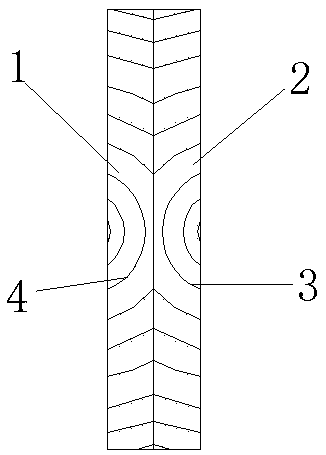

[0025] Select two semicircular woods and cut them into two planks A1 and B2 with similar annual rings in the planks as a group for use;

[0026] 3) Trimming:

[0027] Push the convex surfaces of the annual rings A3 and B4 of the two boards A1 and B2 with similar annual rings to level off for later use;

[0028] 4) Paste:

[0029] Spread a layer of yellow glue on the protruding surfaces of the annual rings of the two planks A1 and B2 that are similar to the annual rings A3 and B4 after being flattened. The annual rings A3 and B4 are included, and the an...

Embodiment 2

[0031] A kind of plank anti-deformation method of the present invention comprises the following steps:

[0032] 1) Cutting:

[0033] Cut the wood that has just been felled into sections of the required length, cut the wood at the center of the annual rings of the wood, and cut the two semicircular woods into planks with equal thickness. Make neat planks of required thickness and width for use;

[0034] 2) Selection board:

[0035] Select two semicircular woods and cut them into two planks A1 and B2 with similar annual rings in the planks as a group for use;

[0036] 3) Trimming:

[0037] Push the convex surfaces of the annual rings A3 and B4 of the two boards A1 and B2 with similar annual rings to level off for later use;

[0038] 4) Paste:

[0039] Spread a layer of white latex on the raised surfaces of the annual rings of the two planks A1 and B2 that are similar to the annual rings A3 and B4 after being flattened. With the recessed surface of wheel A3 and annual ring ...

Embodiment 3

[0041] A kind of plank anti-deformation method of the present invention comprises the following steps:

[0042] 1) Cutting:

[0043] Cut the wood that has just been felled into sections of the required length, cut the wood at the center of the annual rings of the wood, and cut the two semicircular woods into planks with equal thickness. Make neat planks of required thickness and width for use;

[0044] 2) Selection board:

[0045] Select two semicircular woods and cut them into two planks A1 and B2 with similar annual rings in the planks as a group for use;

[0046] 3) Trimming:

[0047] Push the convex surfaces of the annual rings A3 and B4 of the two boards A1 and B2 with similar annual rings to level off for later use;

[0048] 4) Paste:

[0049] Spread a layer of universal glue on the convex surfaces of the annual rings of the two planks A1 and B2 that are similar to the annual rings A3 and B4 after being flattened. With the recessed surface of wheel A3 and annual ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com