Beaker cleaning and drying integrated device

A technology of rotating connection and bottom plate, applied in the direction of drying gas arrangement, drying, drying machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

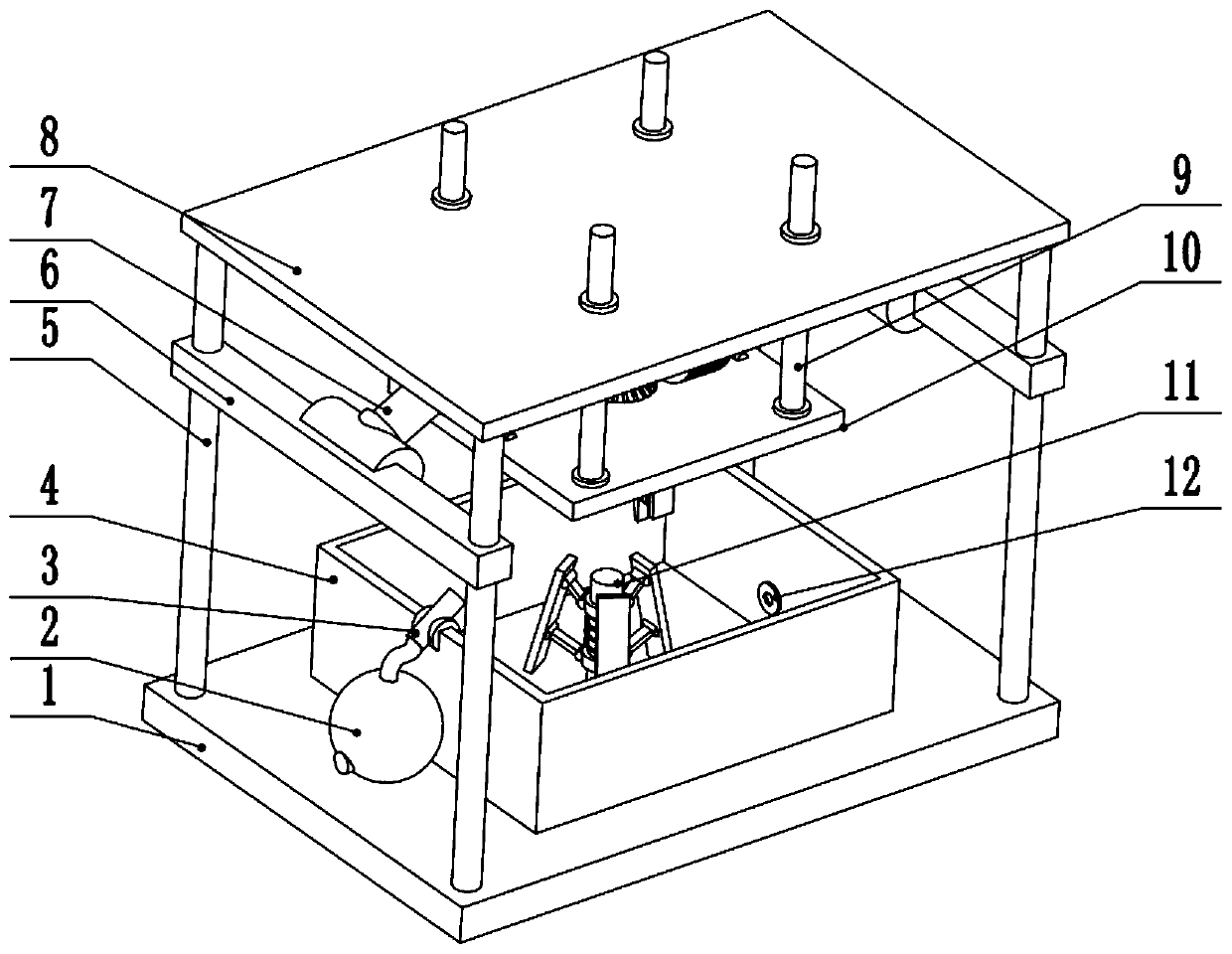

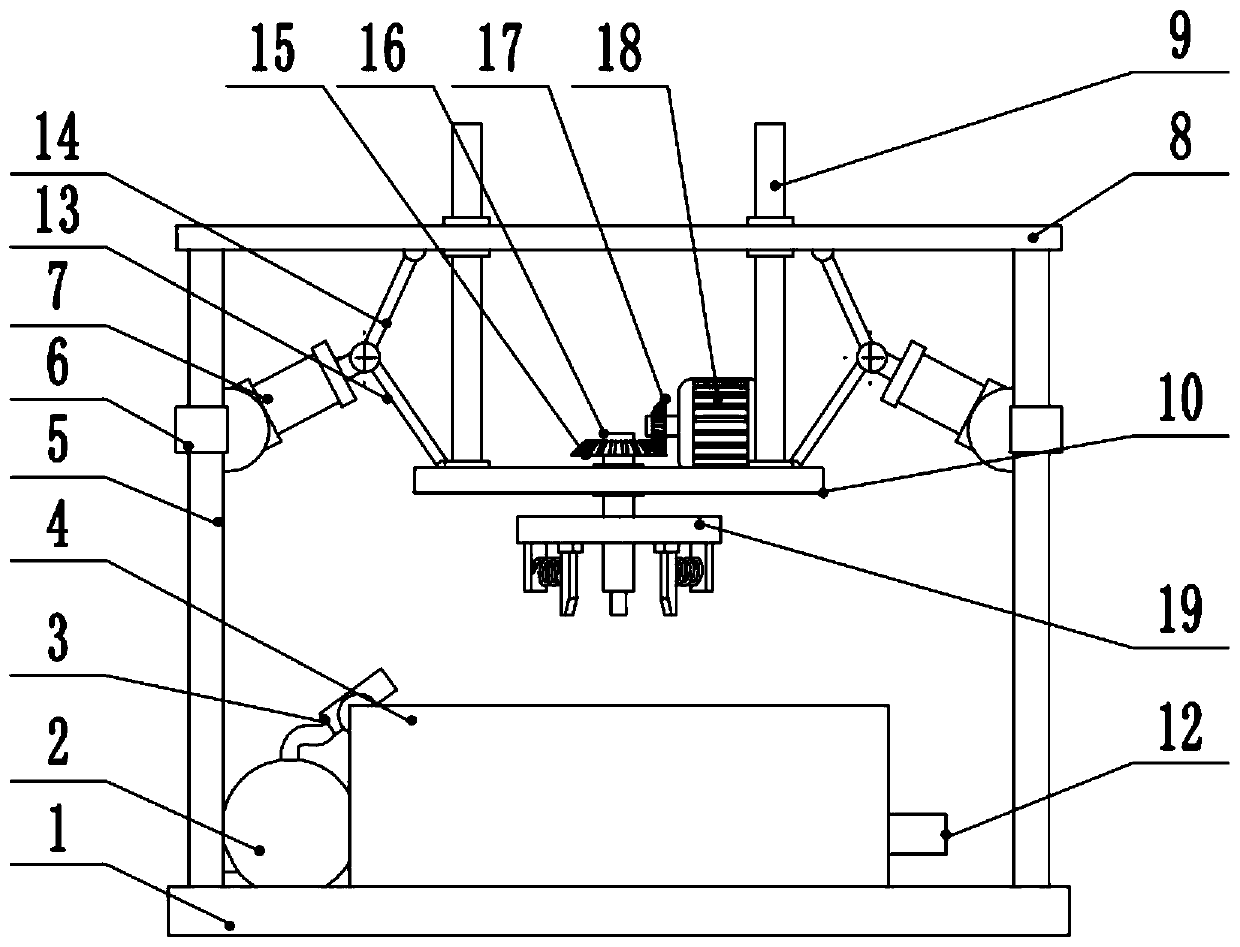

[0026] see Figure 1-4 , an integrated device for cleaning and drying beakers, comprising a base plate 1, a water tank 4 is provided in the middle of the upper surface of the base plate 1, support columns 5 are provided on the left and right sides of the upper surface of the base plate 1, and a top plate is provided at the upper end of the support column 5 8. The left and right sides of the top plate 8 are slidingly connected to the guide rod 9, the lower end of the guide rod 9 is connected to the lifting plate 10, the right side of the lifting plate 10 is provided with a driving motor 18, and the output shaft of the driving motor 18 is fixedly connected to the first bevel gear 17. The first bevel gear 17 meshes with the second bevel gear 15. The second bevel gear 15 is fixedly connected to the upper end of the rotating shaft 16. The middle part of the rotating shaft 16 is connected to the middle part of the lifting plate 10. The lower end of the rotating shaft 16 is connected ...

Embodiment 2

[0030] The other content of this embodiment is the same as that of Embodiment 1, except that: the nozzle 3 is provided with a heating device inside. In order to increase the drying speed of the beaker, the nozzle 3 with a heating device inside is used. When the nozzle 3 sprays out the air flow, the heating device can heat it, so that the cold air is heated into hot air. By blowing the hot air on the beaker On, increase the volatilization speed of water stains on the surface of the beaker, and complete the drying process for the beaker.

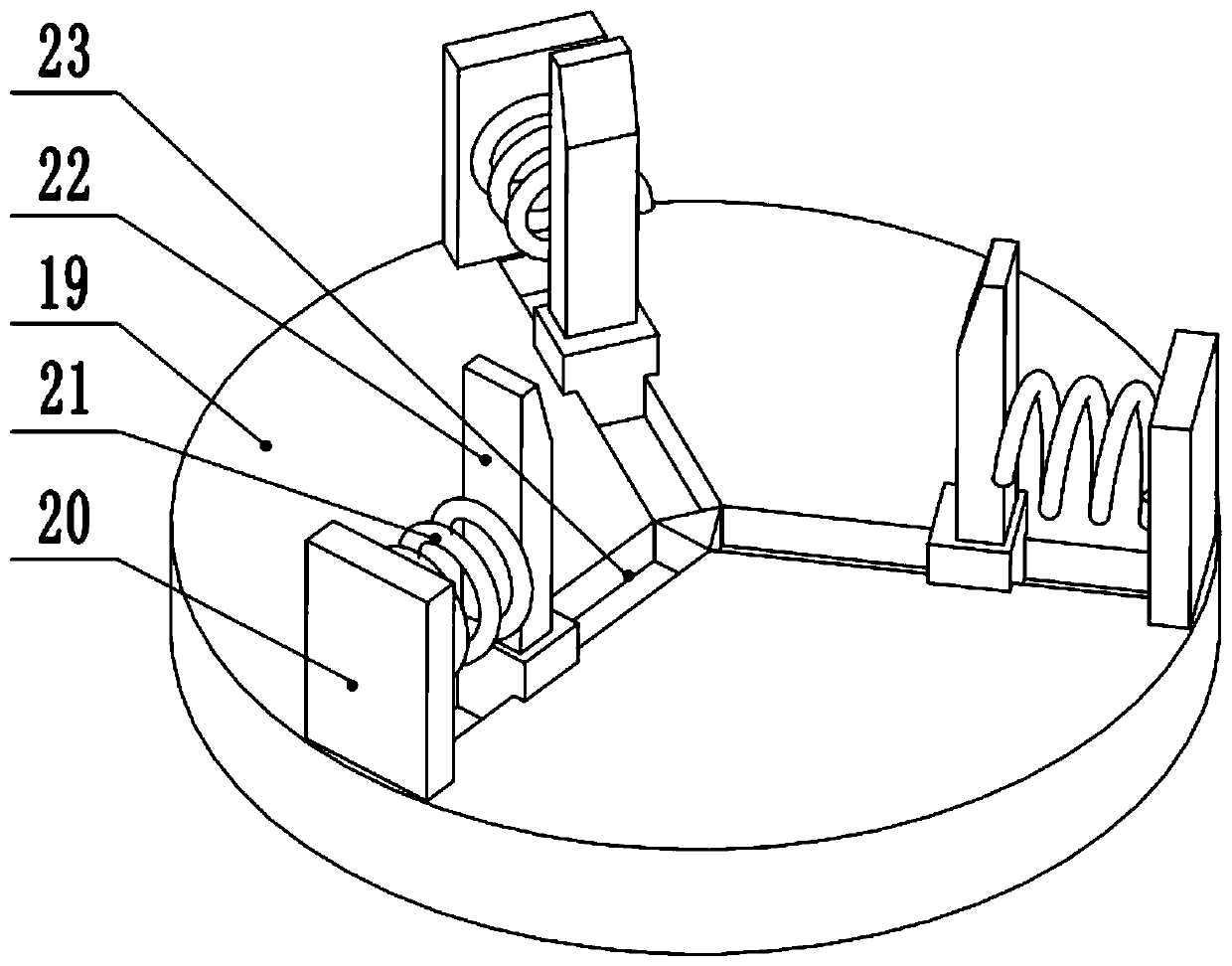

[0031]During the implementation of the present invention, the Prime Minister injects cleaning solution into the water tank 4, holds the beaker to be cleaned with the opening facing down, and presses the bottom of the beaker between the three sliders 22. The ends of the sliders 22 Both parts are provided with chamfers. When the bottom of the cup is pressed in, the bottom of the cup pushes the slider 22 to slide toward the outside of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com