Environment-friendly equipment used in paint spraying workshop

A technology for environmental protection equipment and workshops, applied in the direction of spraying devices, etc., can solve the problem that the bottom cover of the dust removal mechanism is not easy to open, and achieve the effects of avoiding high pressure, enhancing stability, and strengthening support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

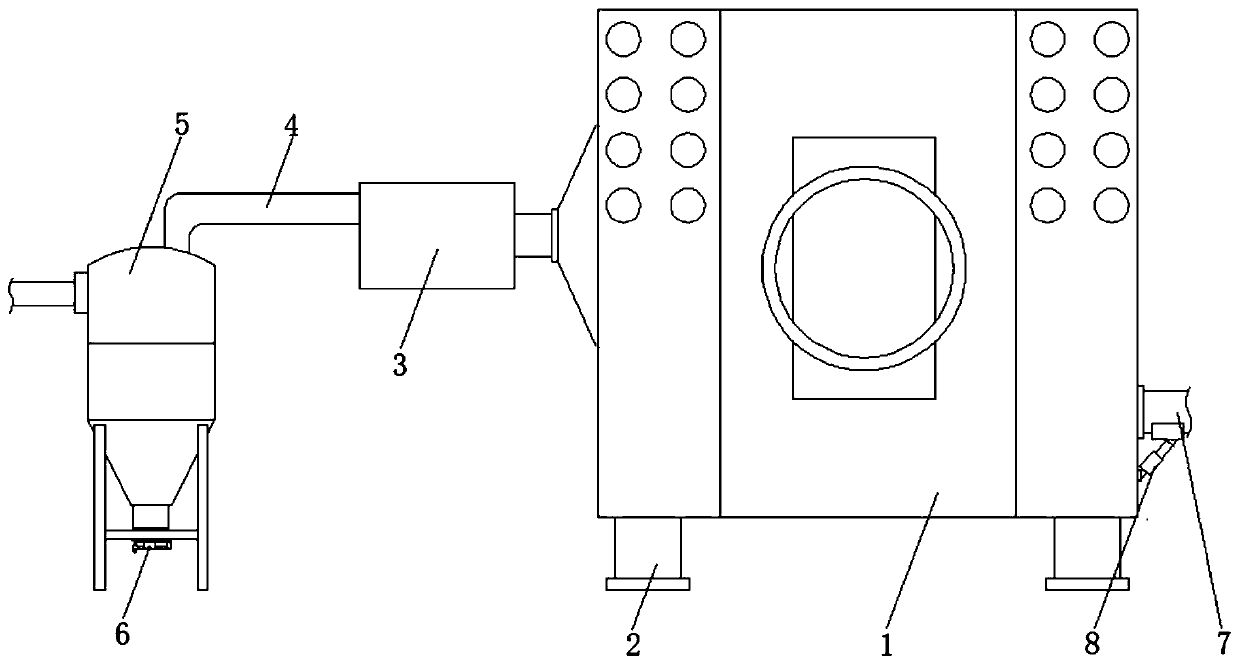

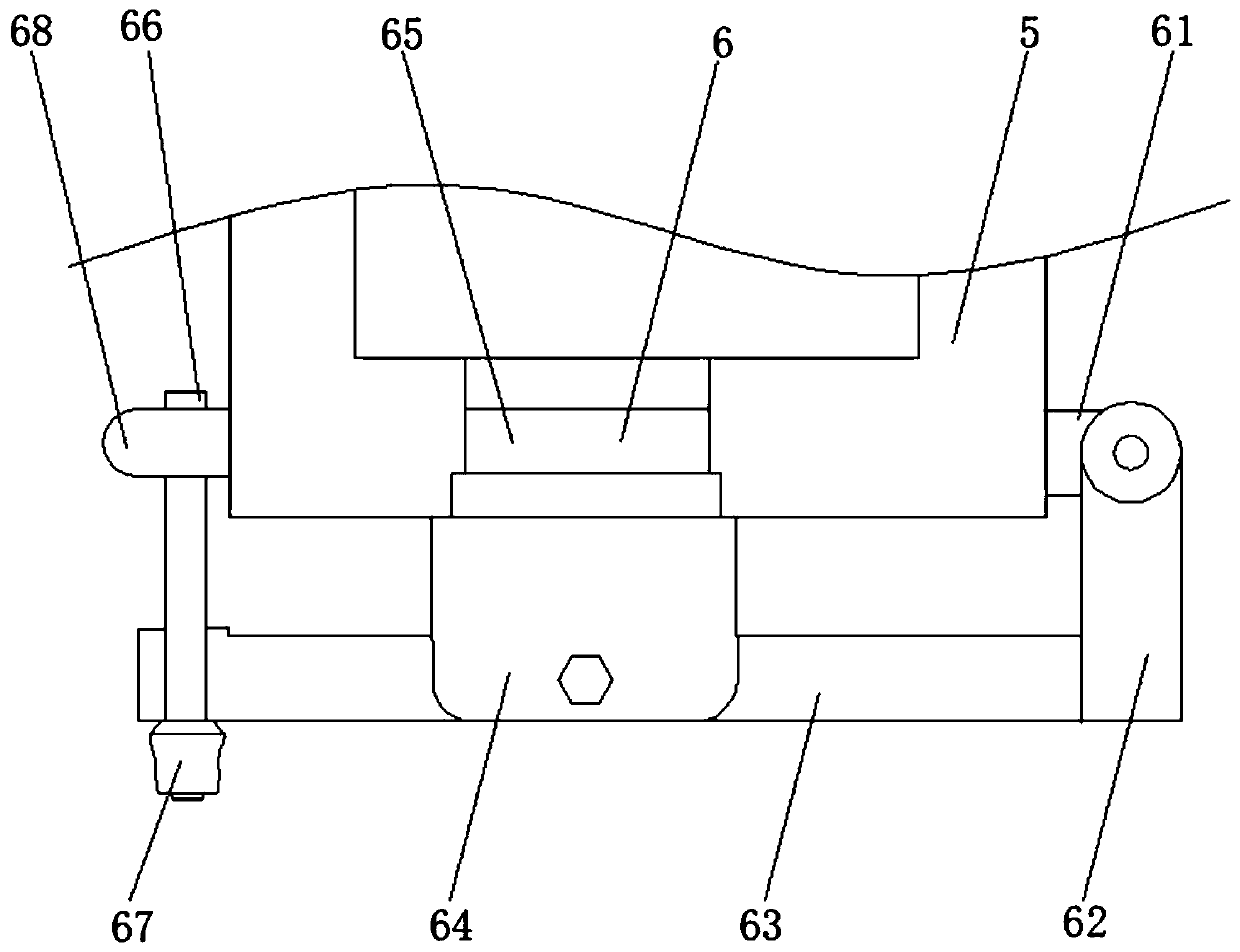

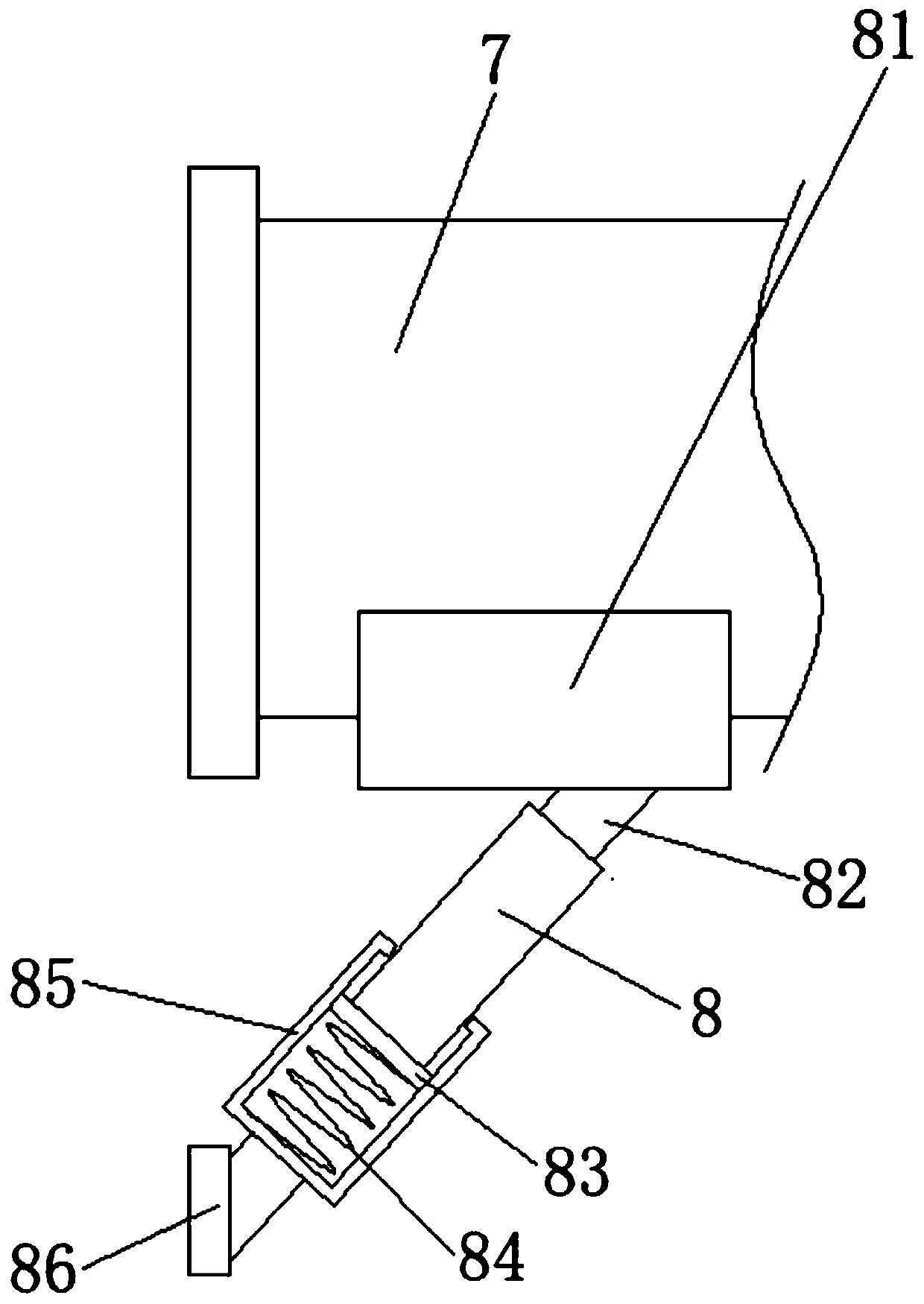

[0020] see Figure 1-2 , the present invention provides a technical solution: the environmental protection equipment used in the painting workshop includes a high-temperature plasma incineration mechanism 1, the bottom of the high-temperature plasma incineration mechanism 1 is provided with a support foot 2, and one side of the high-temperature plasma incineration mechanism 1 is connected to an induced draft fan through a pipeline 3. The other side of the induced draft fan 3 is connected to a connecting pipe 4, and the other end of the connecting pipe 4 is connected to a dust removal mechanism 5. The bottom of the dust removal mechanism 5 is provided with a locking mechanism 6, and one side of the high temperature plasma incineration mechanism 1 is provided with an outlet The air duct 7 is equipped with a supporting mechanism 8 on one side of the high-temperature plasma incineration mechanism 1 .

[0021] In this embodiment, preferably, the locking mechanism 6 includes a mount...

Embodiment 2

[0026] see Figure 1-3 , the present invention provides a technical solution: the environmental protection equipment used in the painting workshop includes a high-temperature plasma incineration mechanism 1, the bottom of the high-temperature plasma incineration mechanism 1 is provided with a support foot 2, and one side of the high-temperature plasma incineration mechanism 1 is connected to an induced draft fan through a pipeline 3. The other side of the induced draft fan 3 is connected to a connecting pipe 4, and the other end of the connecting pipe 4 is connected to a dust removal mechanism 5. The bottom of the dust removal mechanism 5 is provided with a locking mechanism 6, and one side of the high temperature plasma incineration mechanism 1 is provided with an outlet The air duct 7 is equipped with a supporting mechanism 8 on one side of the high-temperature plasma incineration mechanism 1 .

[0027] In this embodiment, preferably, the locking mechanism 6 includes a mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com