Preparation method of amnion-spongy chitosan composite double-layer wound dressing

A composite bilayer and chitosan technology, applied in the fields of medical science, absorbent pads, tissue regeneration, etc., can solve the problem of difficult to take into account the rapid healing of wound exudate and wound recovery, and achieve the effect of rapid absorption and prevention of wound infection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The optimization of the decellularization condition of embodiment 1 amniotic membrane

[0031] Four conditions were used to decellularize the amniotic membrane. Rinse the fresh amniotic membrane with deionized water, then soak the amniotic membrane in 0.25% or 0.5% trypsin solution, stir for 2 hours, wash it with deionized water, and treat it in 1% SDS aqueous solution for 12 hours or 24 hours. After treatment, the amniotic membrane was fully washed with deionized water, and after natural air drying, it was stained with DAPI. The results of DAPI staining are shown in figure 1 . By observing the amount of DNA residues, it can be found that when 0.5% trypsin is used for 2 hours, and then 1% SDS is used for 24 hours, the cells in the amniotic membrane are efficiently and thoroughly removed, so 0.5% trypsin is selected for 2 hours to combine 1% SDS was treated for 24 hours as the decellularization condition of the amnion.

Embodiment 2

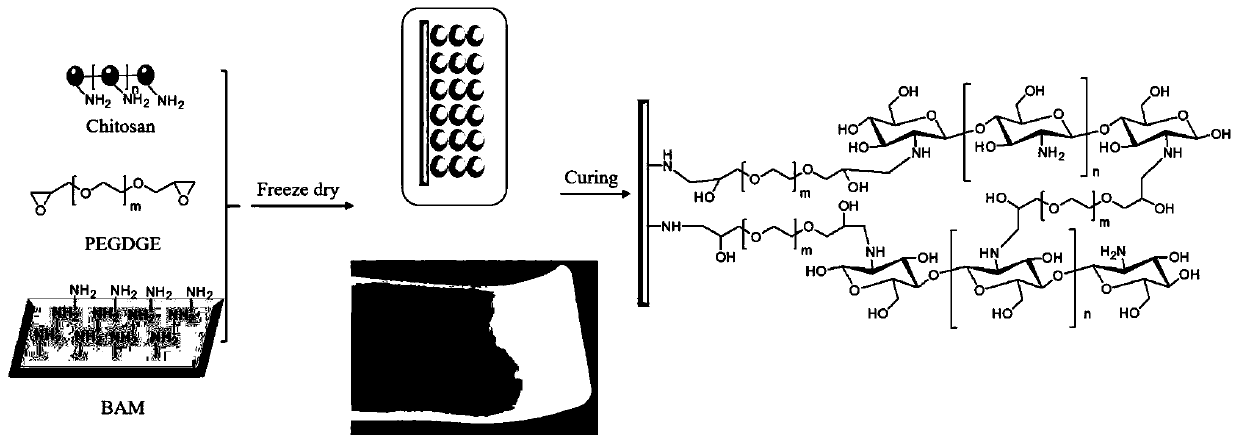

[0032] The synthesis of embodiment 2 double-layer dressings

[0033] For the synthesis flow chart of double-layer dressing, see figure 2 . The specific steps are as follows: cut the decellularized amniotic membrane into a rectangle of 3 cm × 10 cm and place it in a mold, dissolve chitosan in 1% acetic acid aqueous solution to prepare a 20 mg / ml solution, and prepare amniotic membrane: chitosan: cross Add chitosan and cross-linking agent solution to the amniotic membrane at a mass ratio of 1:1:0.2 or 1:3:0.6 (m / m / m) with PEGDGE to prepare double-layered membranes M1-1 with different thicknesses, M1-3, after freezing at -80°C, freeze-dry. After lyophilization, the mold was transferred to an oven at 40°C, and the reaction was continued for 6 hours. Finally, a cross-linked double-layer dressing is obtained, and the finished product of the double-layer dressing is shown in image 3 . The prepared double-layer dressing was characterized by scanning electron microscopy, and the...

Embodiment 3

[0034] The effect of embodiment 3 different double-layer dressings on mouse wound healing

[0035] 0.1mol / L sodium citrate buffer solution: add 2.10g of citric acid to 100ml of double distilled water to make a citric acid mother solution, which is called liquid A; add 2.94g of trisodium citrate to 100ml of double distilled water to make a sodium citrate mother solution, It is called liquid B; mix liquids A and B at a ratio of 1:1.32 (v / v), and adjust the pH of the solution to 4.0.

[0036] Streptozotocin (STZ) solution: Dissolve STZ in 0.1mol / L sodium citrate buffer to prepare a STZ solution with a concentration of 10mg / mL, and filter it with a 0.22μm bacteria filter. Pay attention to the preparation in the dark, and use it now.

[0037] All mice were randomly divided into control group and model group, and fasted for 12 hours before operation. The mice in the model group were injected intraperitoneally with STZ solution at a dose of 70 mg / kg, and the control group was given...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com