Positive electrode material for lithium ion battery, preparation method and application, and battery

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as performance comparison of water-based lithium-ion batteries, high production cost of lithium-ion batteries, and difficulty in manufacturing large-scale energy storage systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

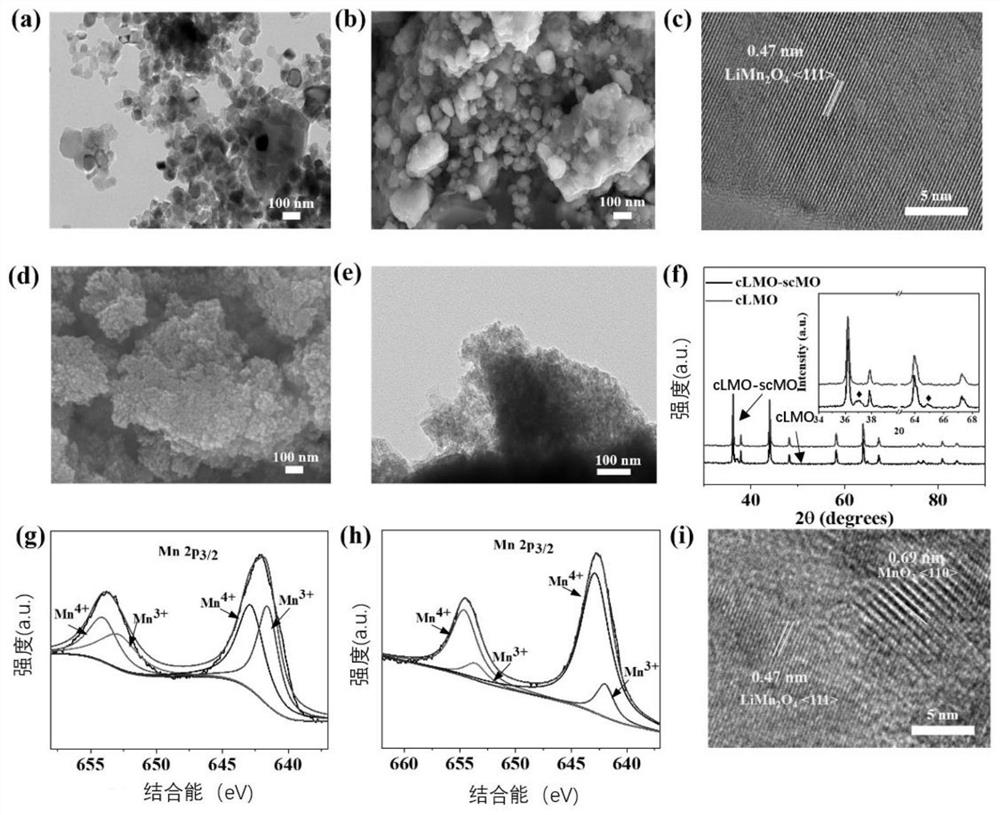

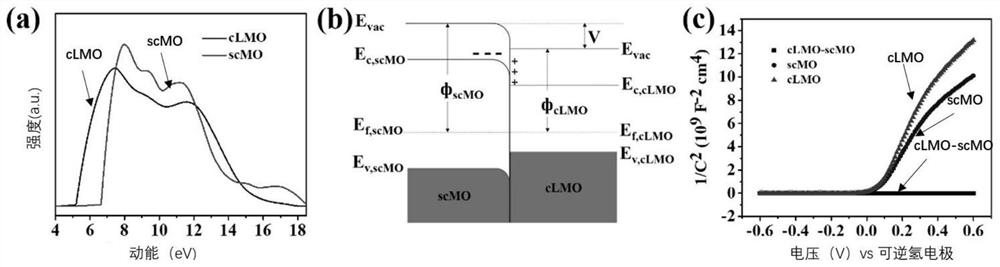

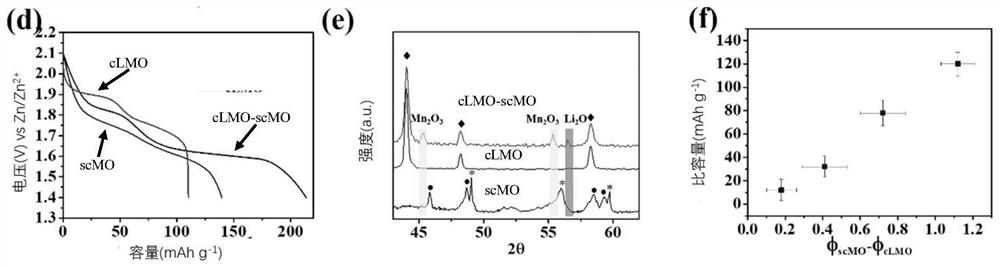

[0044] Example 1 Preparation of cLMO-scMO based on Mn element

[0045] In this step, cLMO material is provided first. The synthesis of cLMO can be carried out by a hydrothermal method commonly used in the art. Using a low-energy ball mill (Fritsch Pulverisett 7), 5 g of cLMO (LiMn 2 o 4 ), 0.2mol / L Na 2 S 2 o 8The aqueous solution and 15 g of zirconia / stainless steel mixed ball milling beads of different sizes were placed in a ceramic container, and the total milling time was 7 hours (1200 rpm). Every 1 hour, temporarily stop the ball milling process, remove the container from the mill and place it in an ice bath for 30 minutes. Carefully transfer solids adhering to the inner walls of the vessel into the liquid phase using a spatula to ensure that all particles in the ice bath are cooled at the same temperature. After cooling, the container was returned to the ball mill and ball milling was continued for 1 hour. After a total grinding time of 7 hours, the mixture in th...

Embodiment 2

[0046] Example 2 Preparation of cLMO-scMO based on Co element

[0047] The rest of the steps are basically the same as in Example 1, the difference is that LiCoO is used 2 is cLMO (cLCO), and finally obtains crystalline LiCoO 2 / semicrystalline Co 2 o 3 structured cathode particles.

Embodiment 3

[0048] Example 3 Preparation of HP-cLMO-scMO with hierarchical pore size distribution

[0049] 0.158g KMnO 4 Added to 20ml deionized water, stirred for 2h. Then add 0.084g LiOH and 1ml ethanol, stir for 1h. Finally, the solution was transferred to a 30ml reactor, and after hydrothermal reaction at 180°C for 7h, the solid was collected and dried at 60°C to obtain LMO particles with hierarchical pore size distribution. The low-temperature liquid phase ball milling treatment was the same as in Example 1 to obtain HP-cLMO-scMO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com