Casting three-dimensional feature extraction and similarity measurement method in combination with process parameters

A similarity measurement and three-dimensional feature technology, which is applied in the field of casting three-dimensional feature extraction and similarity measurement combined with process parameters, can solve the problems of indistinguishable individual models of model scale and good matching effect, so as to avoid multiple contributions and achieve good matching effect. , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

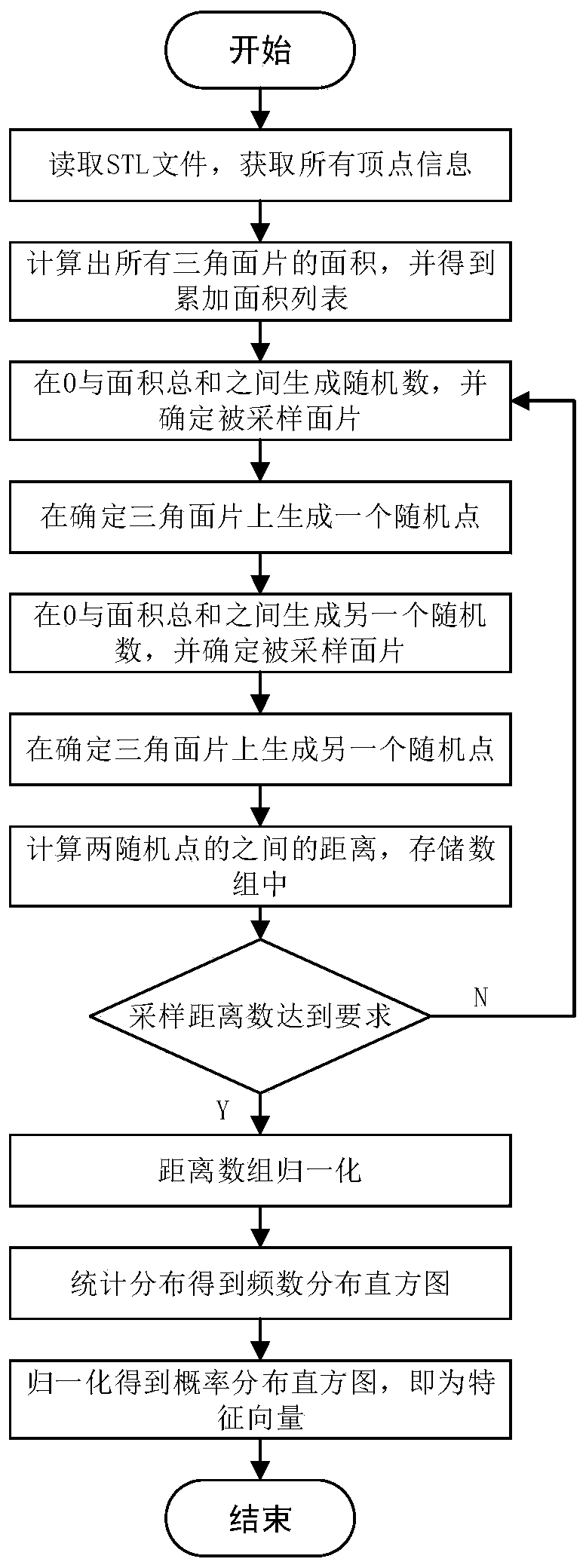

[0066] The D2 shape distribution algorithm, the casting process parameters and the D2 shape distribution algorithm are used to extract the features of the 3D model, and the Euclidean distance is used to measure the similarity; the number of distance values in S115 is n=1×10 6 , the dimension N=128 of the frequency distribution histogram in S116, the number M=5 of the initial matching model in S123, the preset weight w in S3 1 =0.8,w 2 =w 3 = 0.1.

[0067] Such as Figure 4 As shown, it is the top-5 initial matching result obtained only by using the D2 shape distribution algorithm; as Figure 5 As shown, it is the optimal matching result obtained by combining the casting process parameters and the D2 shape distribution algorithm; it can be seen that even in the initial matching result, the D2 operator does not have a high degree of discrimination for the casting model, and cannot distinguish between No. 2 and No. 3 models , but as long as the target model 3 is in the top-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com