System and method for measuring engineering barrier performance parameters of contaminated site

A parameter measurement and engineering technology, applied in measurement devices, suspension and porous material analysis, instruments, etc., can solve problems such as failure to reveal the penetration, dispersion and adsorption mechanism and mechanical properties of engineering barriers, hinder engineering treatment methods, etc. The effect of simulation and improvement of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

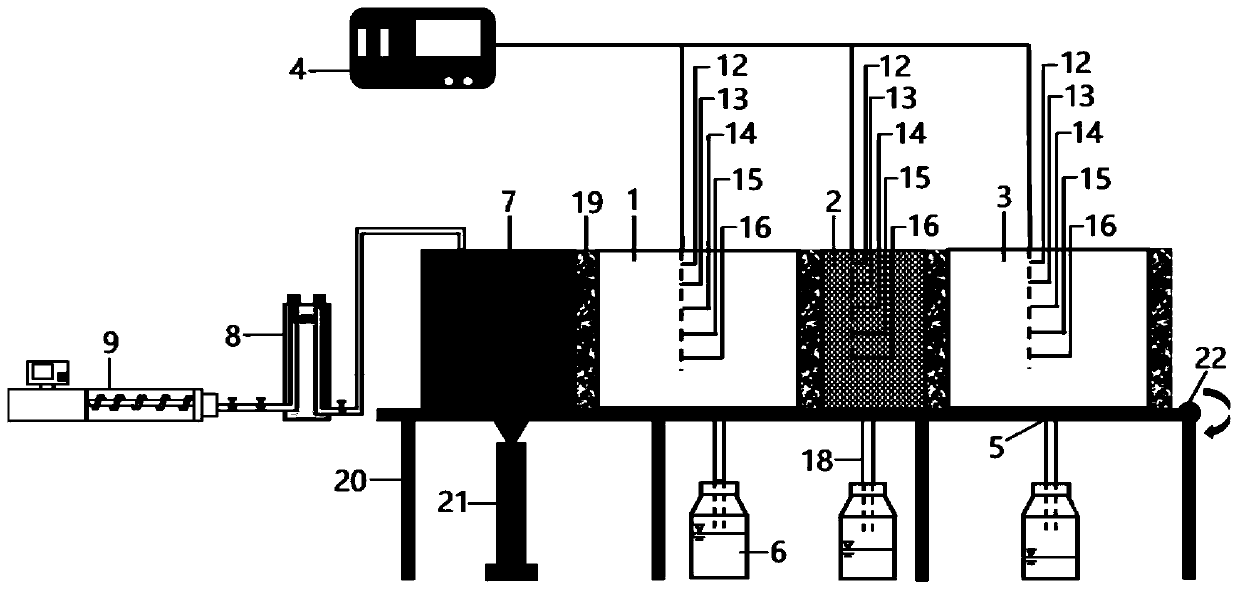

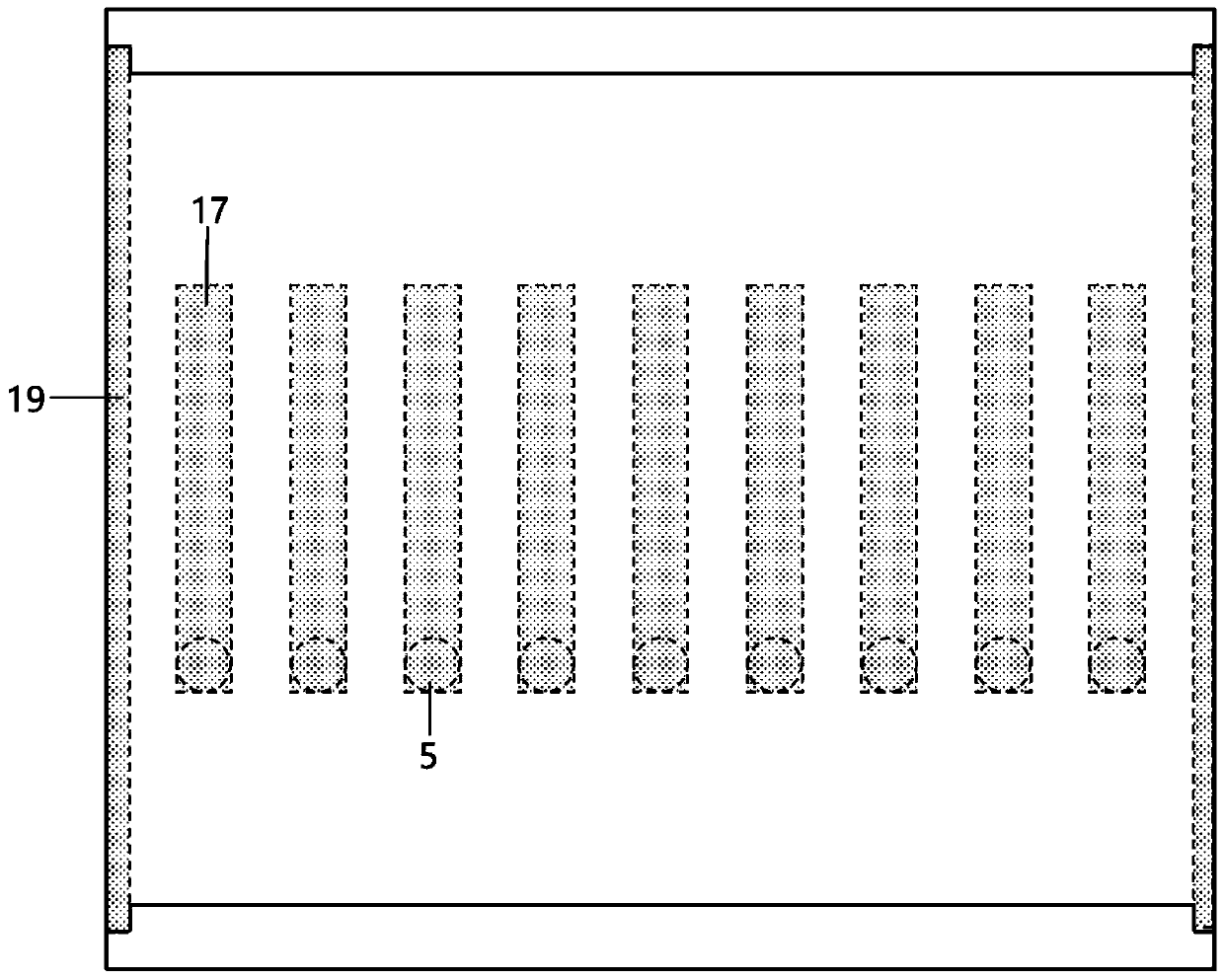

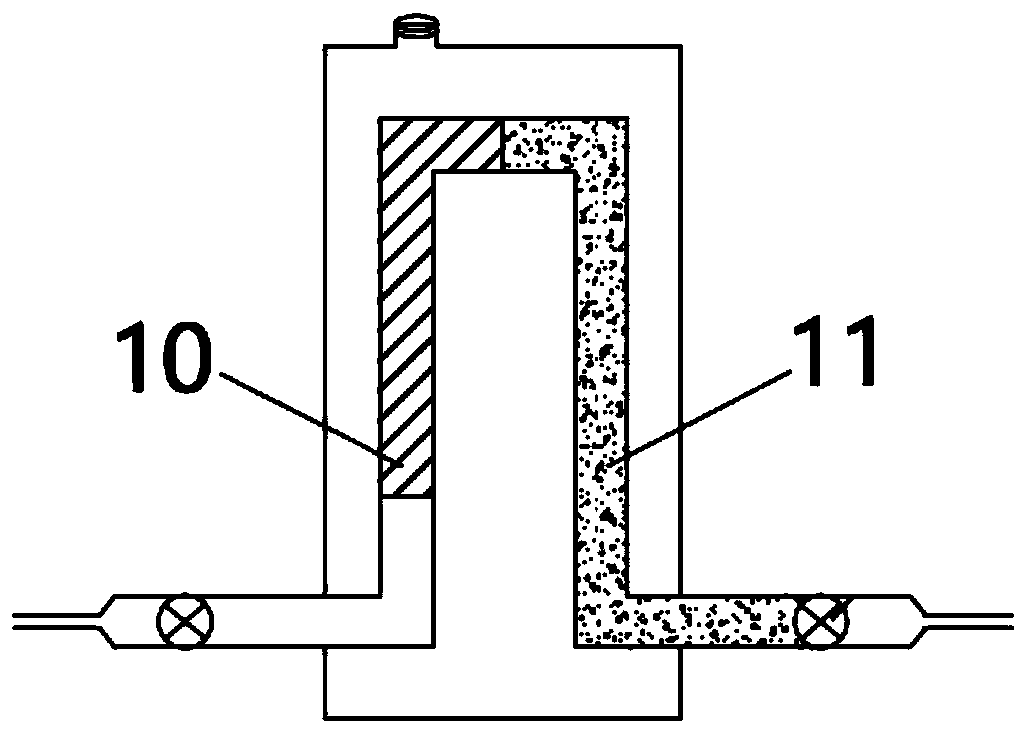

[0036] like figure 1 As shown, the embodiment of the present invention provides a kind of engineering barrier performance parameter measuring system of polluted site, comprises the chemical liquid container 7 that is arranged in sequence, the first original soil container 1, engineering barrier container 2 and the second original soil container 3, the first Both the first raw soil container 1 and the second raw soil container 3 are filled with raw soil samples, and the engineering barrier container 2 is filled with engineering barrier samples, and a permeable structure is arranged between the two adjacent containers. The chemical liquid container 7 is provided with a chemical liquid input device, which can control the input pressure of the chemical liquid, maintain the stability of the pressure and flow rate of the chemical liquid during the test, and allow the chemical liquid to infiltrate the soil sample evenly. A plurality of sensors are uniformly arranged in the first orig...

Embodiment 2

[0044] This embodiment provides a method for measuring performance parameters of engineering barriers in polluted sites, including:

[0045] Step 1, put the undisturbed soil sample and the engineering barrier sample into the first original soil container 1, the engineering barrier container 2 and the second original soil container 3, insert the permeable plate 19 into the permeable slot, and simultaneously place the first original soil container 1. A solution collector 6 is provided at the water outlet 5 of the second original soil container 3 and the engineering barrier container 2 respectively. Displacement sensors 12, temperature sensors 13, humidity sensors 14, pore water pressure sensors 15, earth pressure sensors 16, etc. are uniformly arranged in the first original soil container 1, the second original soil container 3 and the engineering barrier container 2 and are all connected with one The data acquisition instrument 4 is connected; the chemical liquid for testing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com