Runner cone pressure resistance test device of axial-flow Kaplan turbine and control method

A technology of pressure test device and water discharge cone, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of low efficiency, low degree of automation, and threat to the seal of the runner, so as to ensure pressure stability, The effect of high degree of automation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

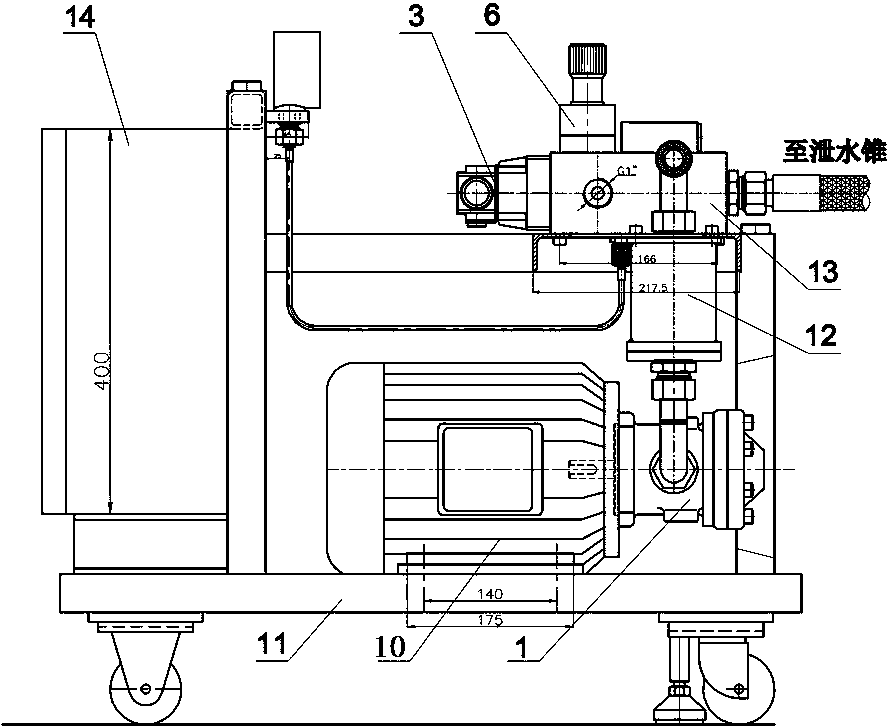

[0020] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

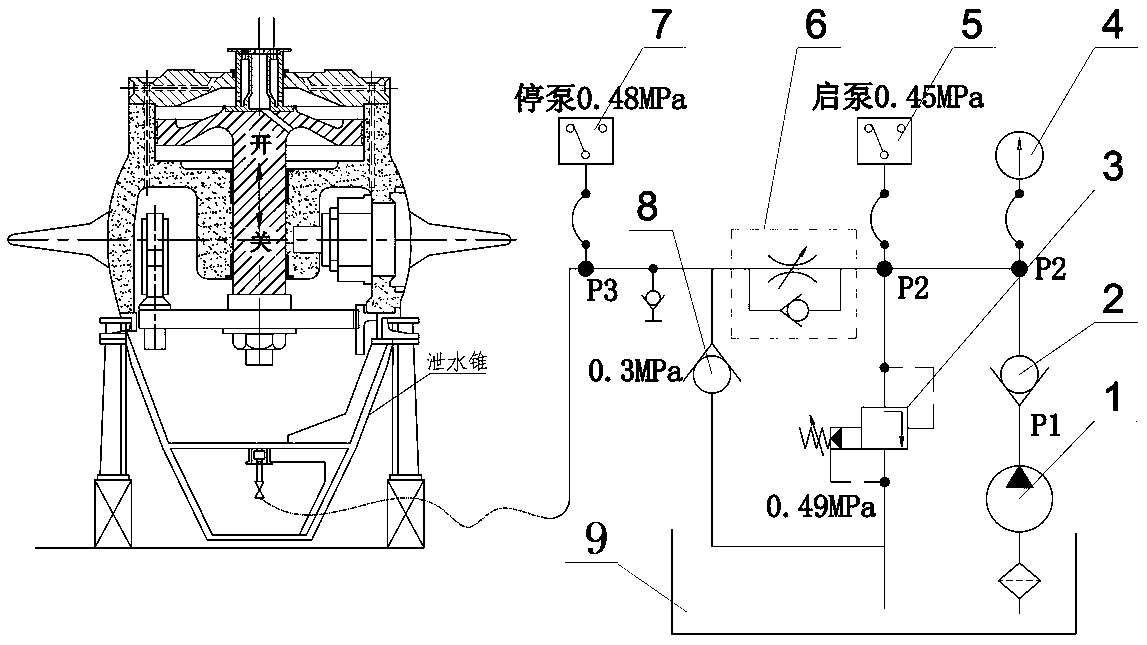

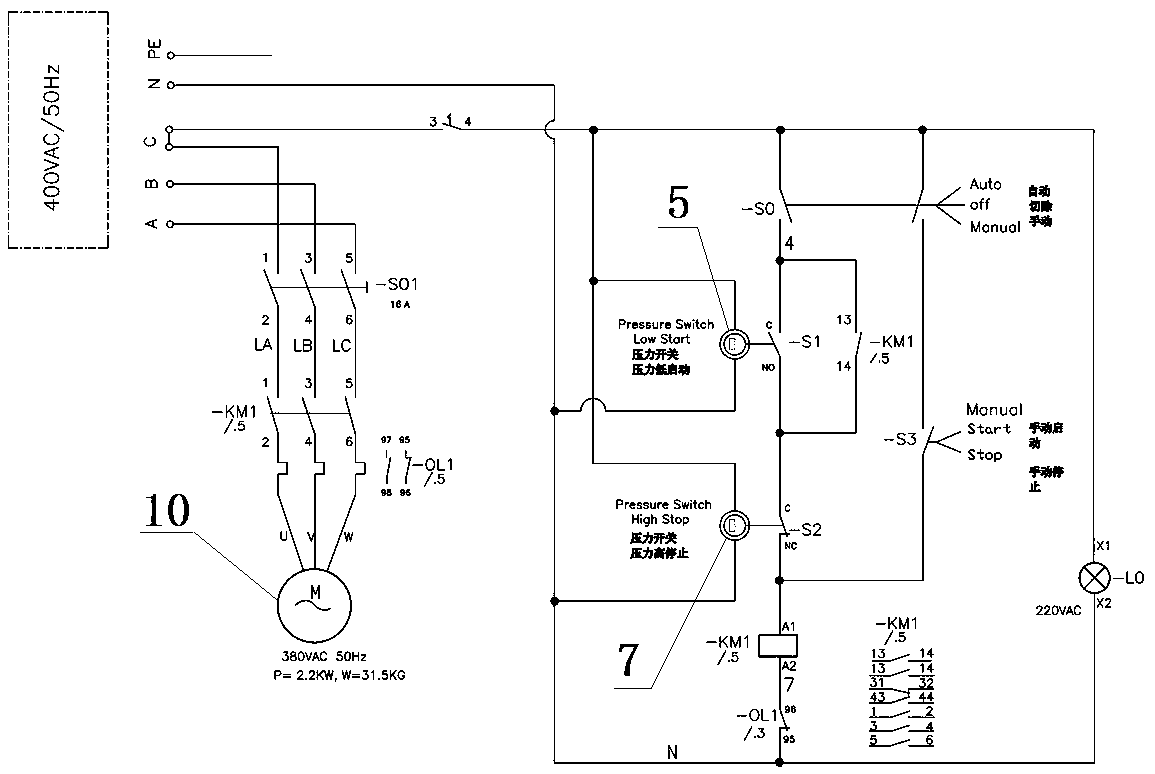

[0021] Such as figure 1 As shown, the device for the pressure test of the discharge cone designed in this implementation is mainly realized through the hydraulic system. The pressure monitoring point of the switch 5, the one-way throttle valve 6 and the pressure monitoring point of the second intelligent pressure switch 7 are connected to the water discharge cone of the runner body of the water turbine; the one-way throttle valve 6 faces one of the pressure monitoring points of the first intelligent pressure switch 5 The side pipeline is connected to the overflow valve 3; the side pipeline of the one-way throttle valve 6 facing the pressure monitoring point of the second intelligent pressure switch 7 is connected to the second one-way valve 8; the overflow valve 3 is connected to the second one-way valve 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com