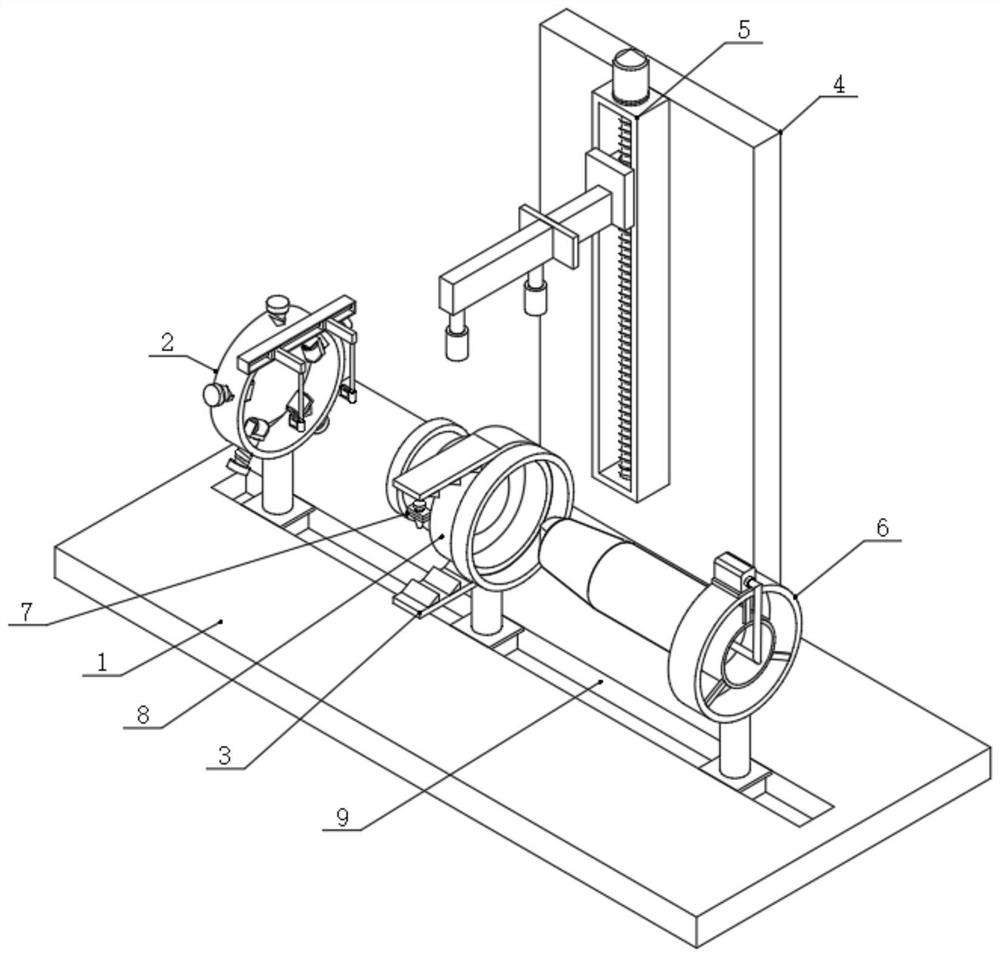

Press-fitting equipment and press-fitting process for fire hose production

A fire hose, press-fitting technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of lack of fire hose insertion adaptability, affecting the ability of fire hose feeding to adapt to processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

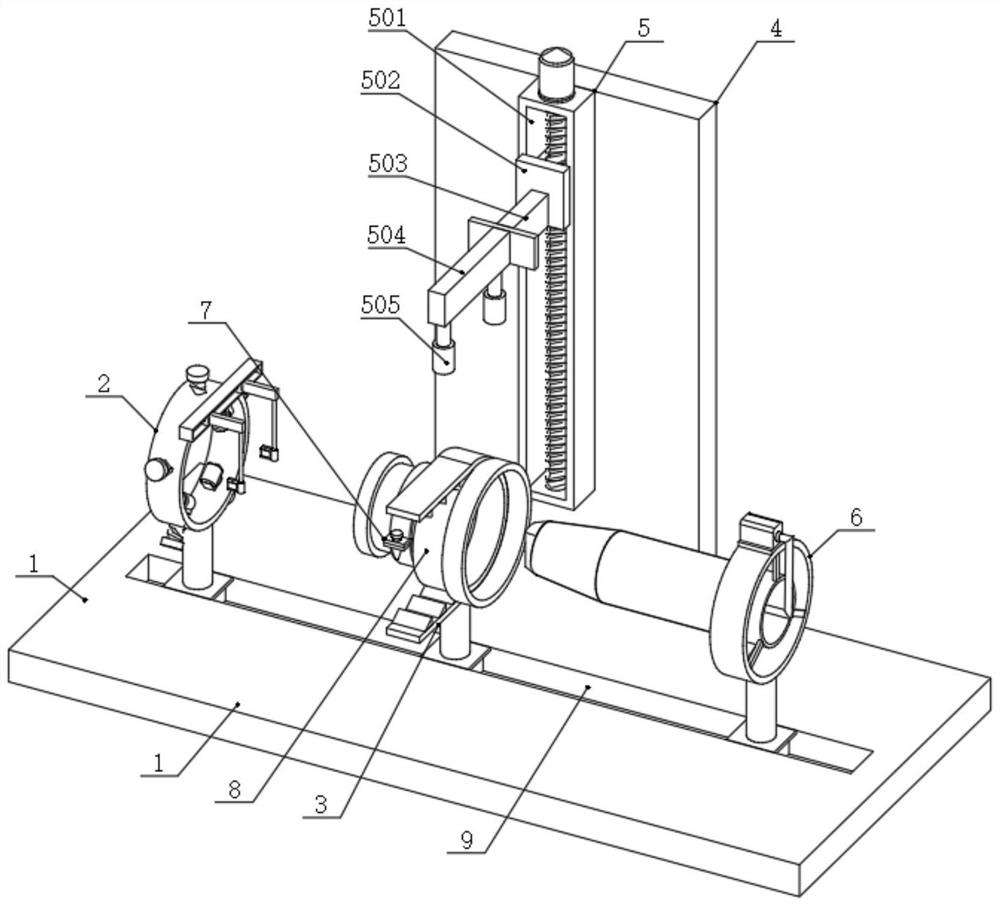

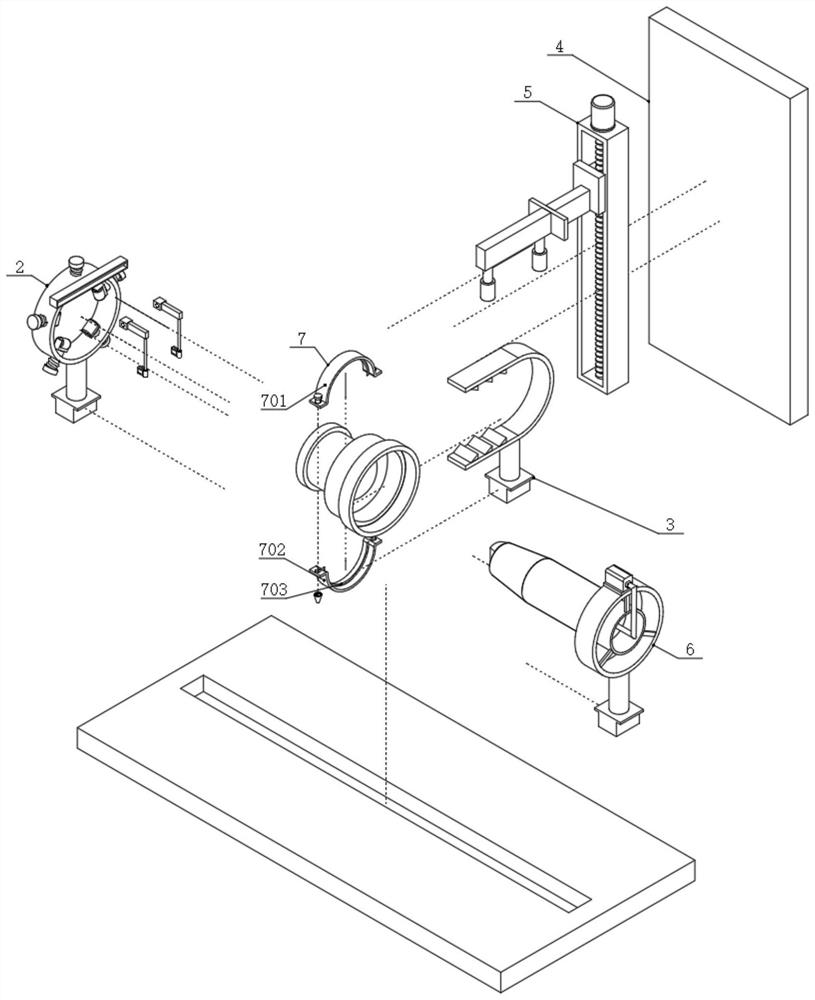

[0040] The specific implementation method is: when the fire hose needs to be press-fitted, by snapping the fire joint main body 8 into the clamping seat 301 at the corresponding position, the limit spring block 302 uses its own elastic force to clamp and limit the outside of the joint main body 8 , the assembled fire hose can pass through the hose assembly ring 201 on one side and then extend to the inside of the fixture body 212 on both sides. The fixture body 212 abuts and stretches both sides of the inner wall of the fire hose through the spring clamp body, and the electric slide rail 9 Drive the electric slide seat and the feed fixed rod 213 to move, the feed fixed rod 213 drives the hose assembly ring 201 to move, and the hose assembly ring 201 can move by pulling the fire hose deployment side to move to the joint main body 8 side, the clamp The main body 212 and the fire hose are inserted into the outside of the tapered sleeve 604 and the guide sleeve roller 603. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com