Boundary lubrication bearing material and production process thereof

A bearing material, boundary lubrication technology, applied in bearing components, shafts and bearings, bearing assembly, etc., can solve the problems of cumbersome disassembly steps of bearing end caps, reduce the efficiency of maintenance work, inconvenient to add lubricating oil, etc., and achieve high reliability. , Guaranteed effect, reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

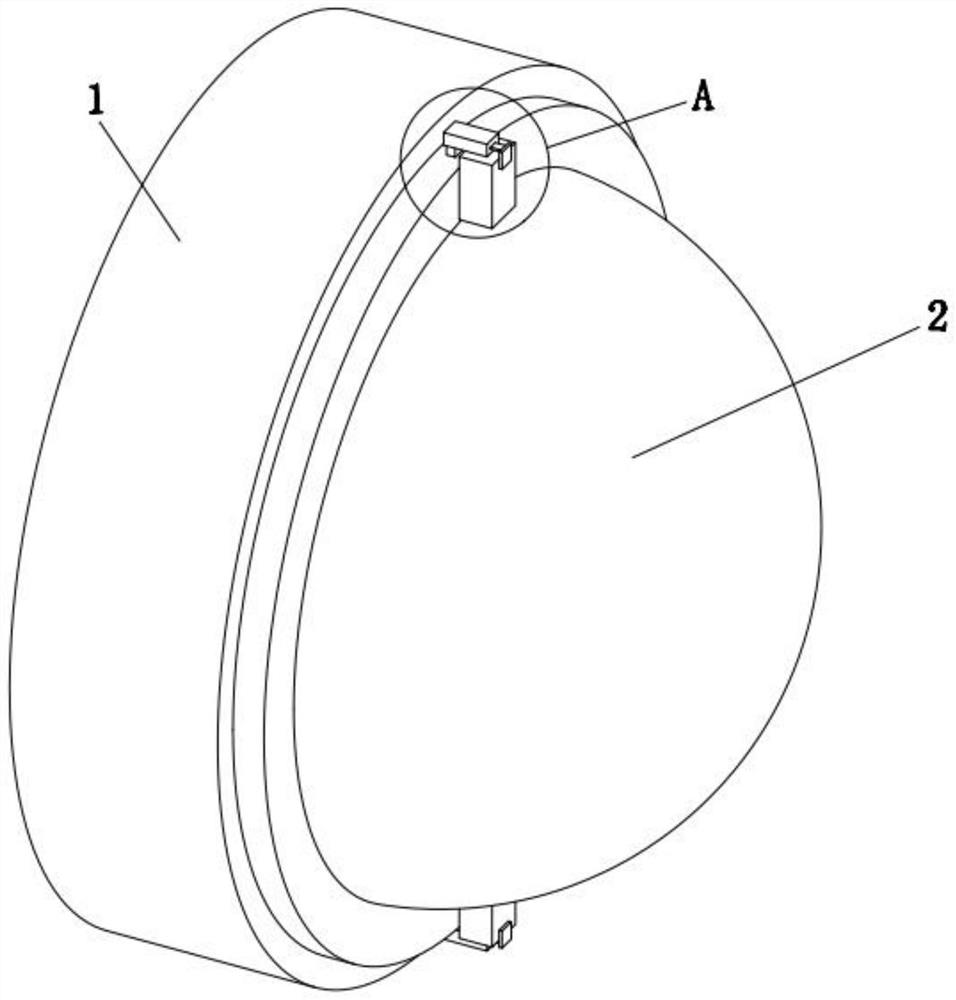

[0022] refer to Figure 1-5 , a boundary lubricated bearing material, including a bearing cylinder 1, a bearing end cover 2 and a mounting assembly, the bearing end cover 2 is movable and sealed against one side of the bearing cylinder 1, and the mounting assembly includes a connecting plate 3, a horizontal plate 4, and a vertical plate 5 and the connecting column 8, the connecting column 8 is fixedly installed on one side of the bearing cylinder 1, two vertical bars 20 are fixedly connected on the horizontal plate 4, and the same slide plate 16 is fixedly installed on one end of the two vertical bars 20, on the slide plate 16 A positioning plate 17 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com