Odor treatment device for garbage leachate treatment station

A landfill leachate and treatment device technology, applied in gas treatment, dispersed particle filtration, combustion methods, etc., can solve the problem of harmless reaction of molecules that cannot cause odor, poor effect of harmless treatment of odor, and impact on surrounding environmental quality, etc. problems, to achieve the effect of guaranteeing the effect of treatment, reducing the waste of heat, and ensuring the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

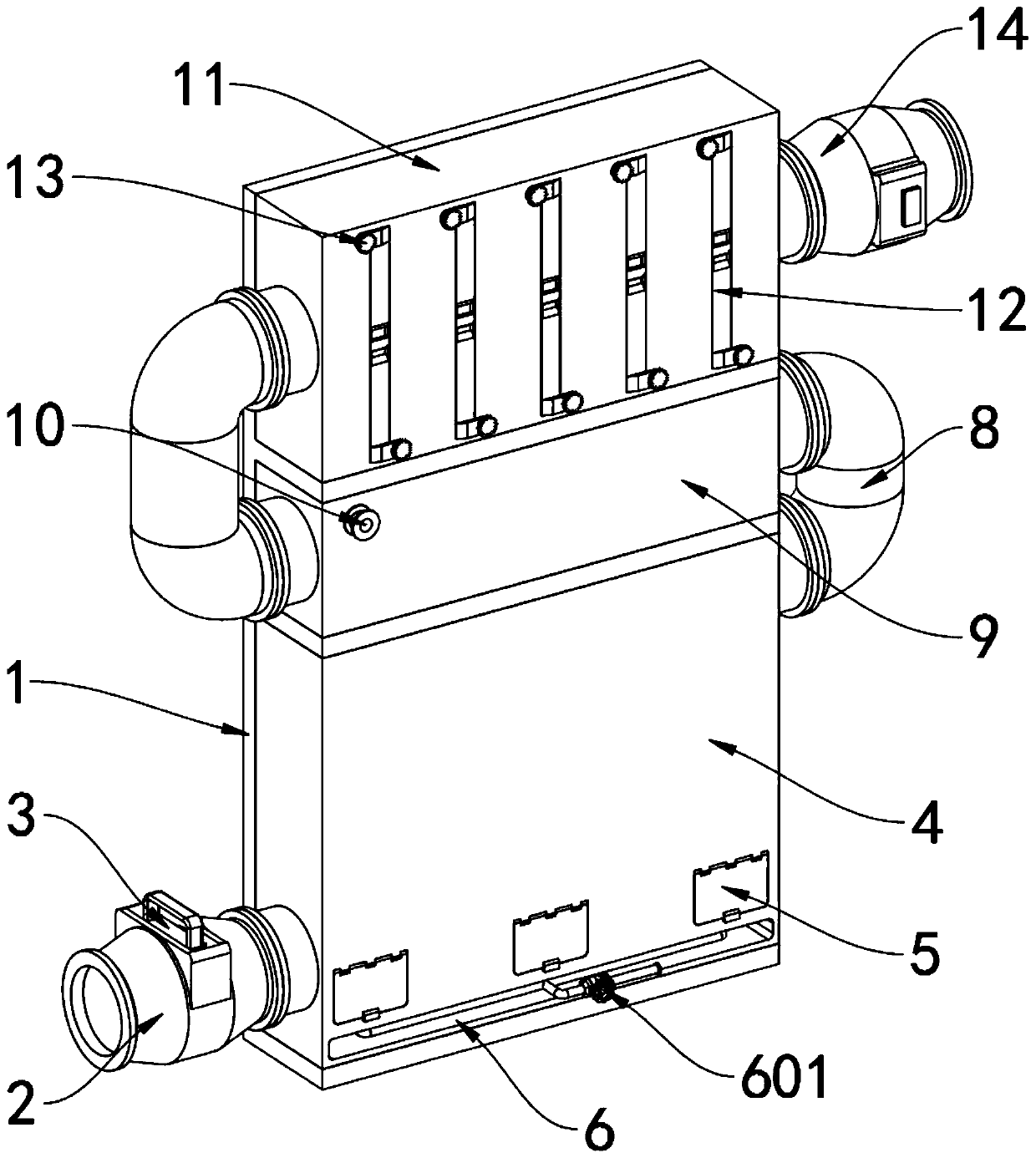

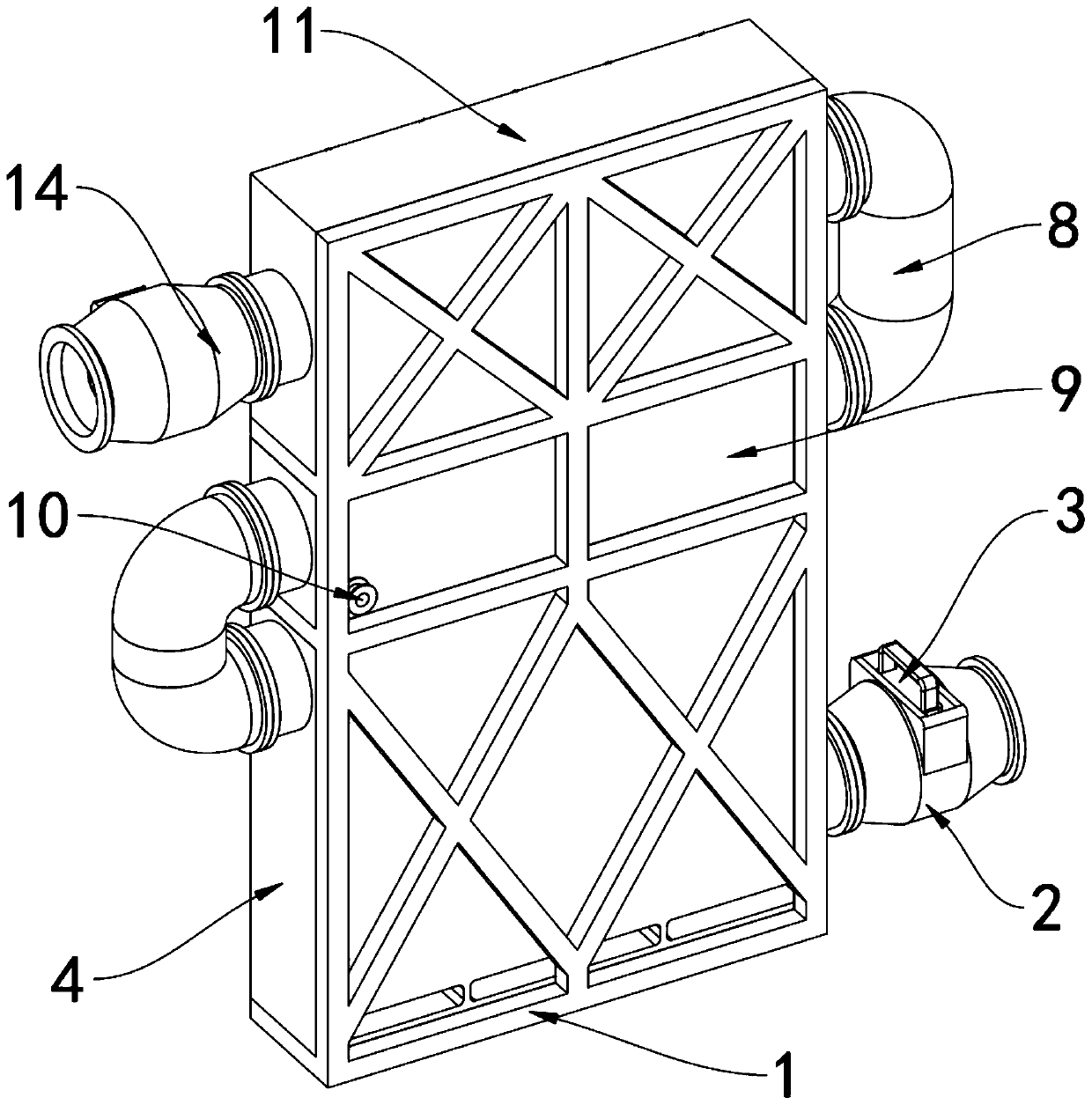

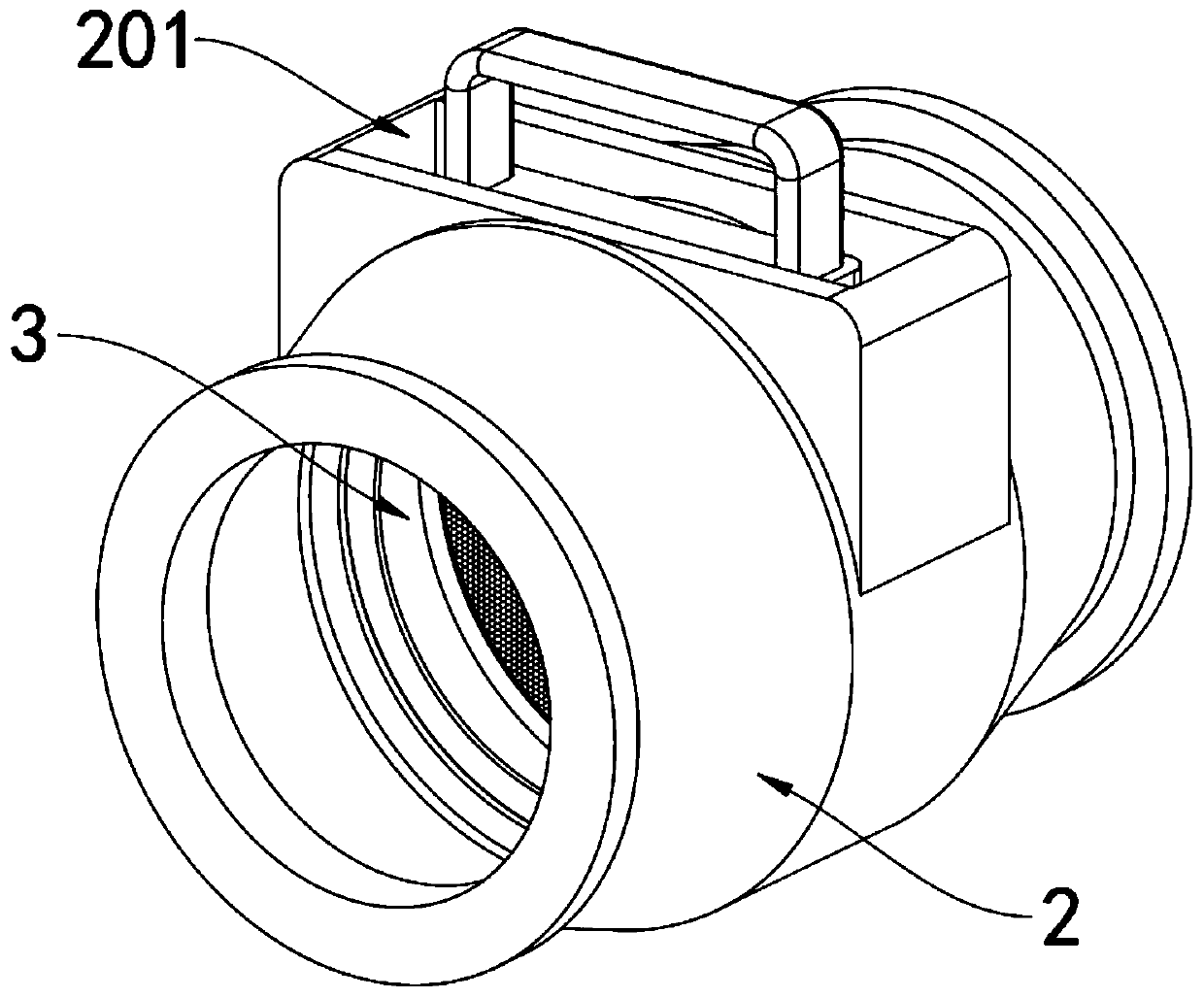

[0032] as attached figure 1 to attach Figure 12 Shown:

[0033]The present invention provides an odor treatment device for a landfill leachate treatment station, comprising a support frame 1, a filter tube 2, a combustion treatment box 4, a sealing baffle 5, a gas pipe 6, a gas nozzle 7, a heat exchange box 9, Activated carbon adsorption plate 12 and blower fan 14, support frame 1 is a frame structure, and combustion treatment box 4 is installed in the bottom of support frame 1; filter pipe 2 inlet end is connected with odor delivery pipeline, and filter pipe 2 outlet end is connected with combustion The air intake end at the bottom of the treatment box 4 is connected, and the filter cartridge 3 is located inside the filter pipe 2; a gas passage 401 is provided inside the combustion treatment box 4, and three gas ignition ports 402 are provided at the front end of the combustion treatment box 4, and the sealing block The plates 5 are respectively rotated and installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com