Air duct connecting and inserting device and using method thereof

A technology of a plug-in device and a connecting device, which is applied in the directions of pipes/pipe joints/pipes, passing components, mechanical equipment, etc., can solve the problems of poor sealing performance of angle iron flanges, increase labor costs, increase the weight of ships, etc., and achieve sealing effect. Good, save labor cost, save construction time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

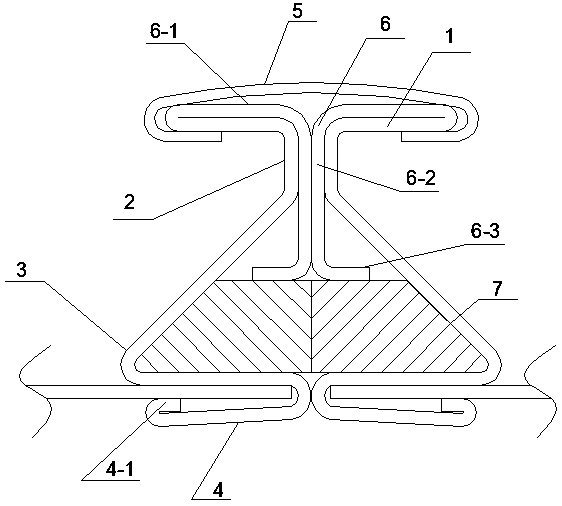

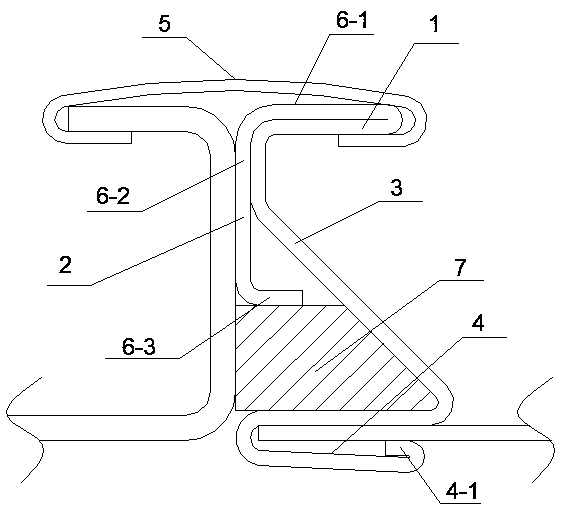

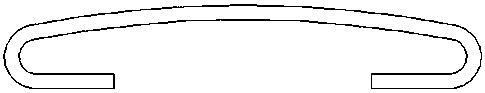

[0037] Such as Figure 1-8 It shows an embodiment of an air duct connecting device of the present invention: it includes a locking cover 5 and an air duct connecting device, and an air duct connecting device is installed at one end of the locking cover 5, or on the locking cover 5 The two ends of 5 are mirror-imaged with an air duct connecting device, the air duct connecting device includes a transverse locking part 1, a longitudinal connecting part 2, a sealing part 3 and a clamping part 4, and the longitudinal connecting part 2 is set at the transverse locking One end of the part 1 is perpendicular to the end face of the transverse locking part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com