Directional cracking device based on carbon dioxide phase change expansion and using method thereof

A technology of phase change expansion and carbon dioxide, which is applied in earth drilling, weapon accessories, blasting barrels, etc., can solve problems such as error-prone, impact on personal health and construction operations, and high requirements on the site environment, and achieve simple and easy-to-operate connections, uniform and Simultaneous heating, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

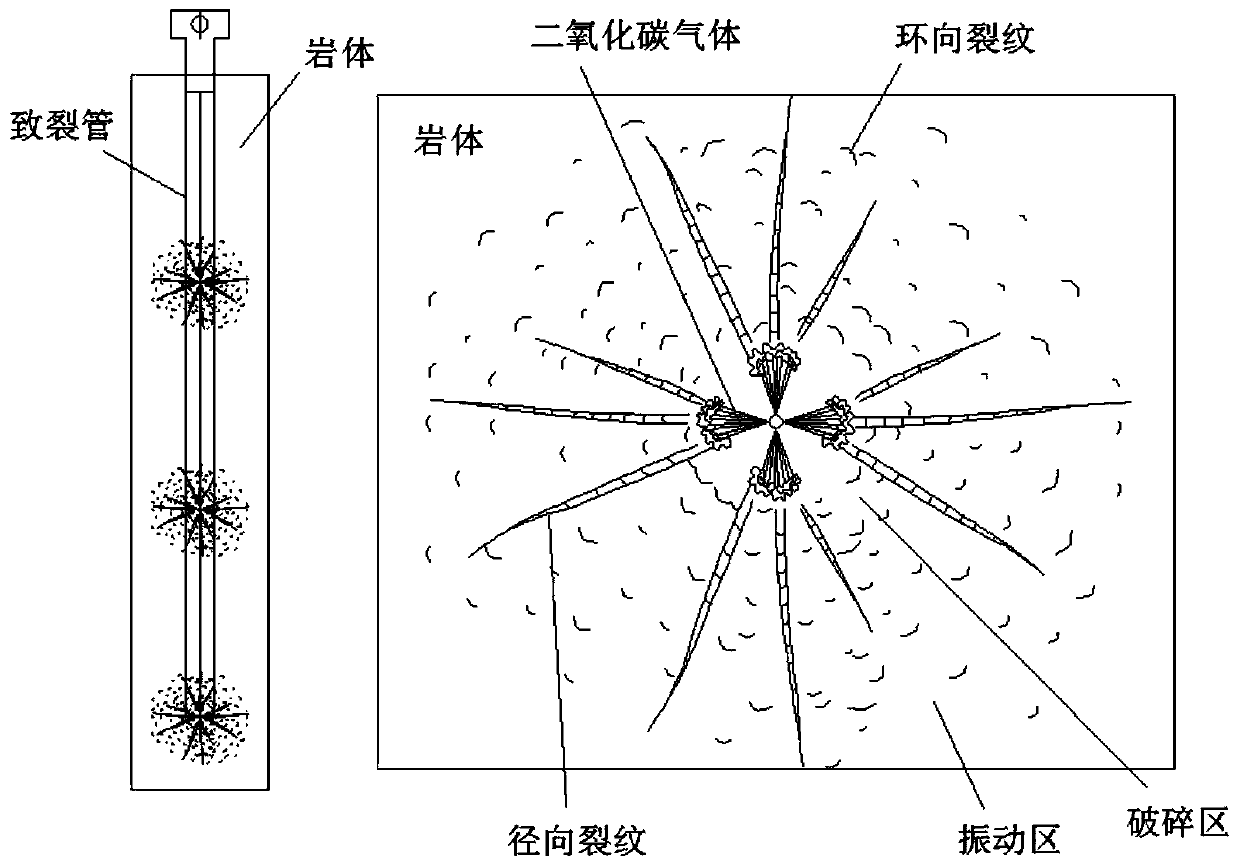

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

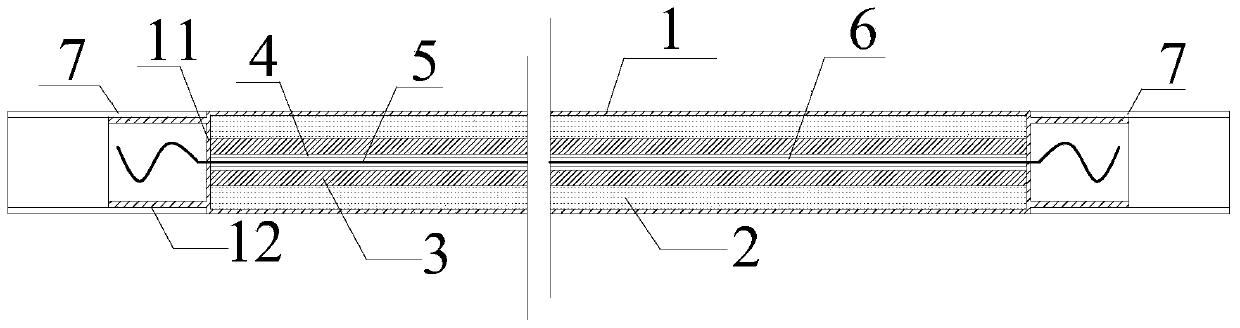

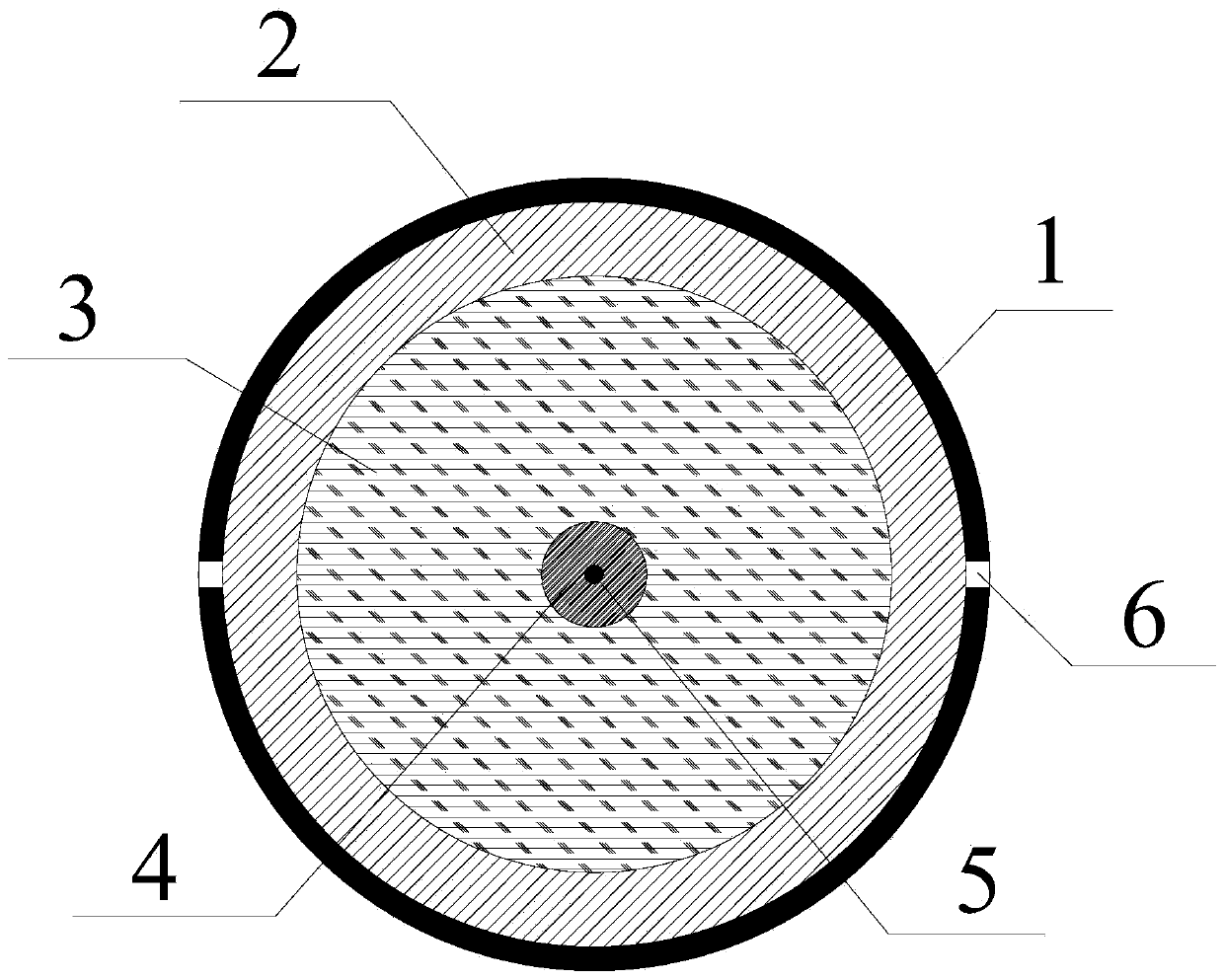

[0032] This embodiment discloses a directional fracturing device based on carbon dioxide phase change expansion, its overall structure is as follows figure 1 with figure 2As shown, an outer casing 1 , a water storage pipe 2 , a liquid storage pipe 3 and a heating pipe 4 are sequentially sleeved from outside to inside, wherein the water storage pipe 2 , liquid storage pipe 3 and heating pipe 4 have the same length. The heating pipe 4 adopts a PVC pipe with a diameter of 20mm and a wall thickness of 2mm. It is arranged inside the liquid storage pipe 3 and the two are designed to be equal in length, so that the contact area between the heating pipe 4 and the liquid storage pipe 3 can be increased, so that it is distributed in the liquid storage pipe 3. The liquid carbon dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com