Periphery hole charging structure for energy-gathered hydraulic pressure smooth blasting, and construction method thereof

A technology of smooth blasting and construction method, applied in blasting and other directions, can solve the problems of difficulty in generating high temperature and high pressure gas, inability to solve, and increase the extension and expansion of initial cracks in rocks, so as to achieve easy formation, sufficient expansion and extension, and reduce dust concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

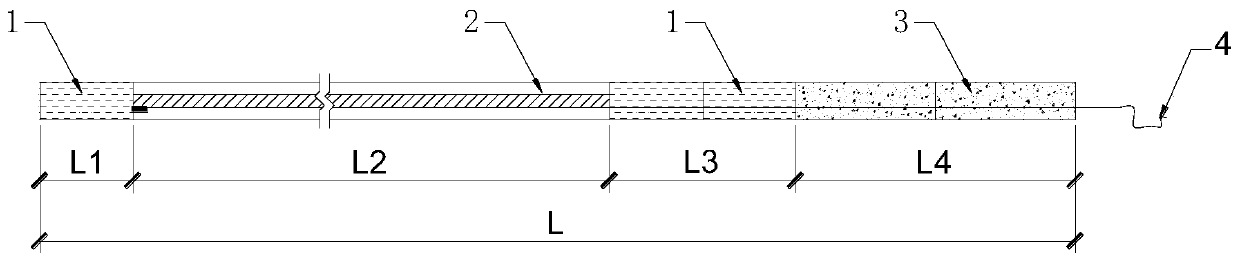

[0068] see figure 1 As shown, a peripheral eye charge structure for energy-gathering water pressure smooth blasting is composed of a blast hole and a water bag 1, an energy-concentrating tube charge bag 2 and a mud 3 arranged in the blast hole. Compared with conventional smooth blasting, the only difference is in the charge structure of the peripheral eye. The energy-gathering tube charge 2 is used to replace the traditional explosive, and the water bag 1 and the mud 3 are added. The depth of the blasthole is L, and the bottom of the blasthole is One water bag 1, the length of the water bag 1 at the bottom of the blasthole is L1, the length of the energy accumulating tube medicine bag 2 is L2, 0.65L≤L2≤0.75L, two water bags 1 in the middle of the blasthole, and two water bags 1 in the middle of the blasthole The length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com