Sludge pyrohydrolysis system

A technology of thermal hydrolysis and sludge, applied in pyrolysis treatment of sludge, vaporization of by-products, etc., can solve the problems of long sludge residence time, low heat transfer efficiency, complex equipment structure, etc., to prevent scaling , the effect of improving the thermal hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

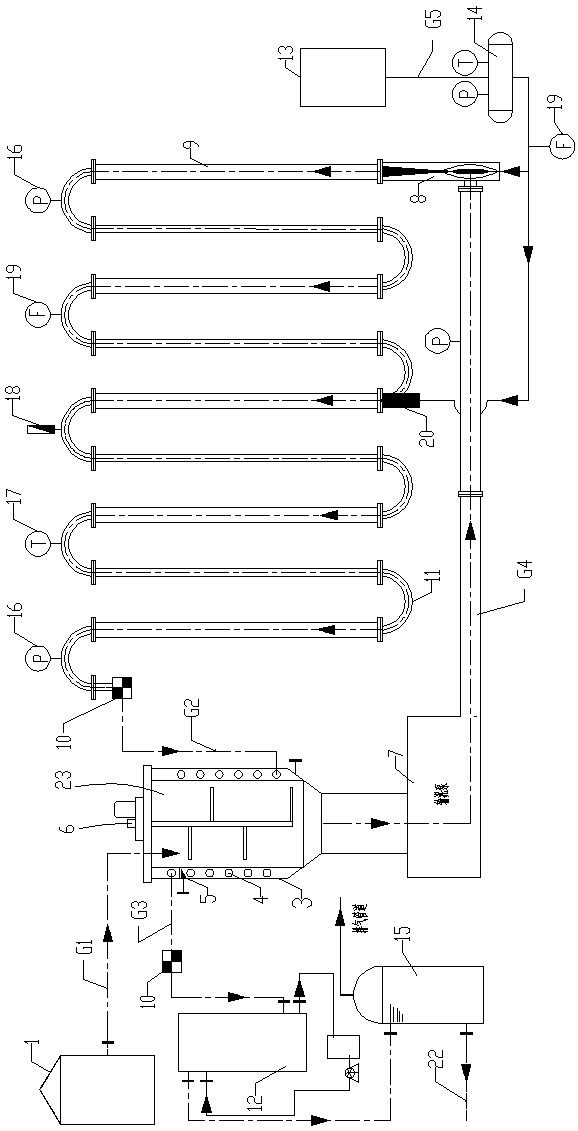

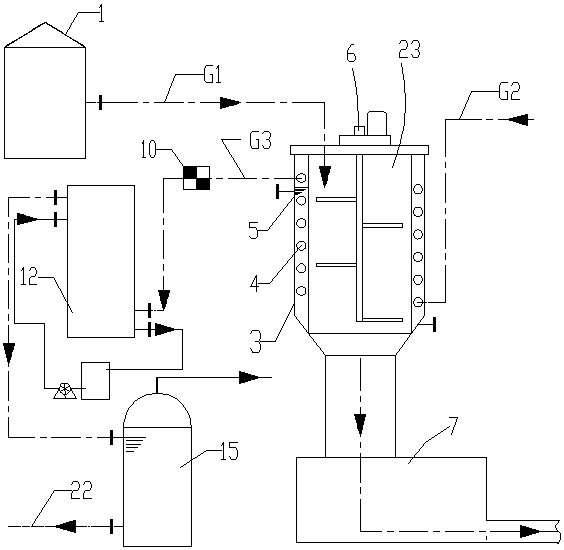

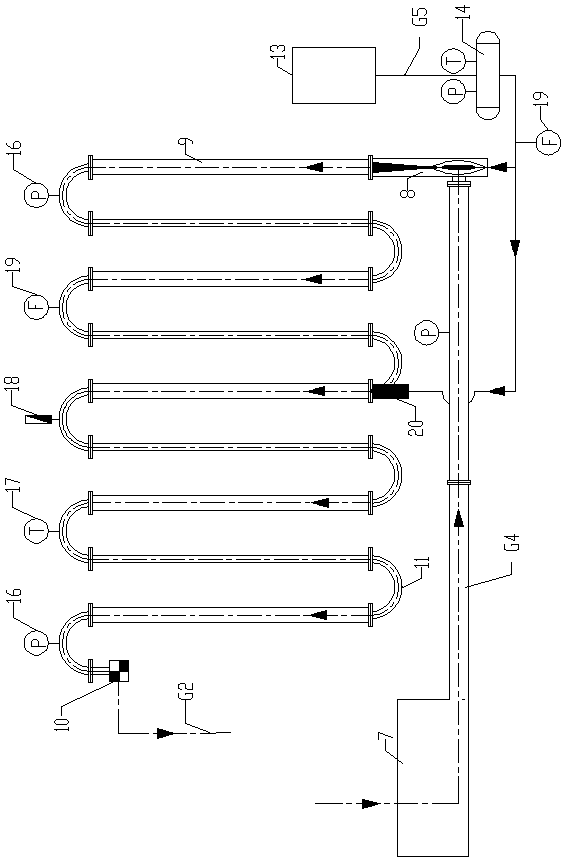

[0022] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 4 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0023] The present invention is a sludge thermal hydrolysis system, comprising a sludge storage tank 1 filled with sludge to be treated, a sludge preheating device 23, a sludge delivery pump 7, a steam source 13, and a pyrolysis sludge storage tank 15. It is characterized in that it is also provided with a sludge thermal hydrolysis pipeline and a steam sludge injector 8, and the outlet of the sludge to be treated in the sludge storage tank 1 communicates with the feed port of the sludge preheating device 23 through the sludge inlet conveying pipeline AG1, The discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com