Adjustable reducing pipe sludge continuous pyrohydrolysis device

A thermal hydrolysis and different-diameter pipe technology, which is applied in the direction of pyrolysis treatment of sludge and by-product vaporization, can solve problems such as sluggishness, uneven heating, and reduced heat transfer efficiency, so as to prevent scaling and thermal hydrolysis Effect of effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

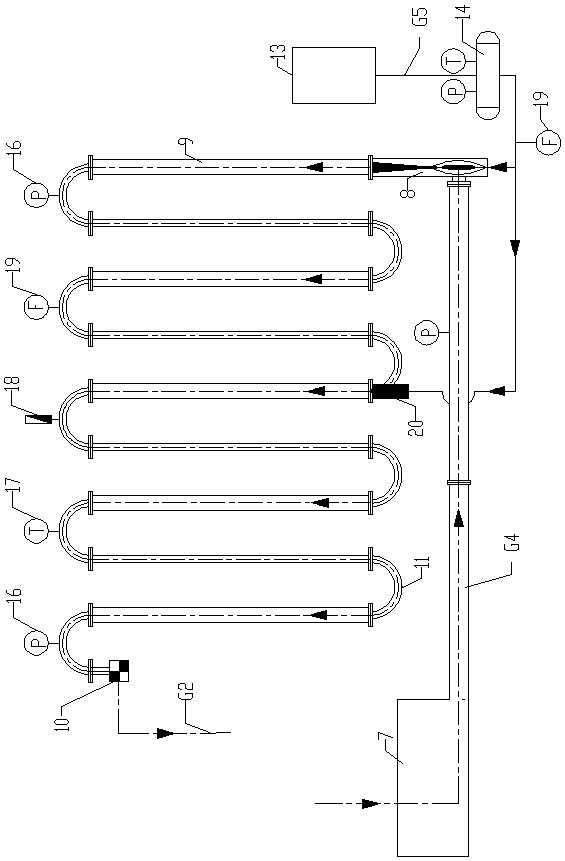

[0023] The present invention is an adjustable different-diameter pipe sludge continuous thermal hydrolysis device. A plurality of cylindrical pipes 9 with different inner diameters are connected to form a sludge thermal hydrolysis pipeline. The outlet of the device 8 is connected, the mud outlet of the mud delivery pump 7 is connected with the first inlet of the steam sludge injector 8 through the mud feeding pipeline BG4, and the steam supply port of the steam source 13 is connected with the steam sludge injector 8 through the steam supply pipeline CG5. The second inlet of the sludge thermal hydrolysis pipeline is connected with a pressure relief discharge device 10 at the thermal hydrolysis sludge outlet of the sludge thermal hydrolysis pipeline, and the pressure relief discharge device 10 leads to the pyrolysis sludge storage tank 15 through the discharge pipeline DG2.

[0024] Preferably, a plurality of cylindrical pipes 9 with different inner diameters are connected throug...

Embodiment 2

[0028] This embodiment is a sludge thermal hydrolysis system including the above-mentioned adjustable reducing pipe sludge continuous thermal hydrolysis device:

[0029] A sludge thermal hydrolysis system, comprising a sludge storage tank 1 filled with sludge to be treated, a sludge preheating device 23, a sludge delivery pump 7, a steam source 13, and a pyrolysis sludge storage tank 15, characterized in that: A sludge thermal hydrolysis pipeline and a steam sludge injector 8 are also provided. The sludge outlet to be treated in the sludge storage tank 1 communicates with the feed port of the sludge preheating device 23 through the sludge inlet conveying pipeline AG1, and the sludge preheater The discharge port of the thermal device 23 is connected with the mud inlet of the mud pump 7, and the mud outlet of the mud pump 7 is connected with the first inlet of the steam sludge ejector 8 through the mud inlet pipeline BG4, and the steam supply port of the steam source 13 The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com