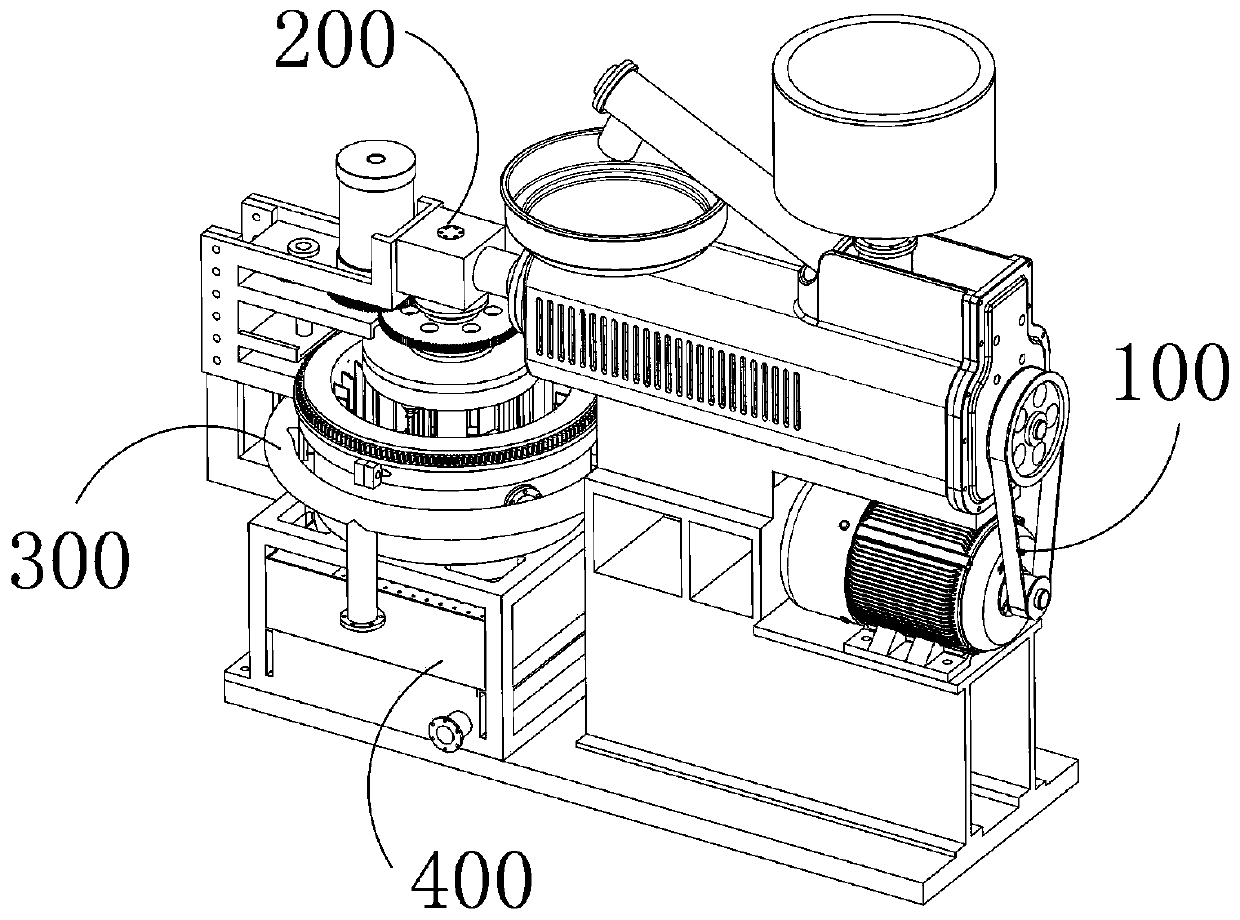

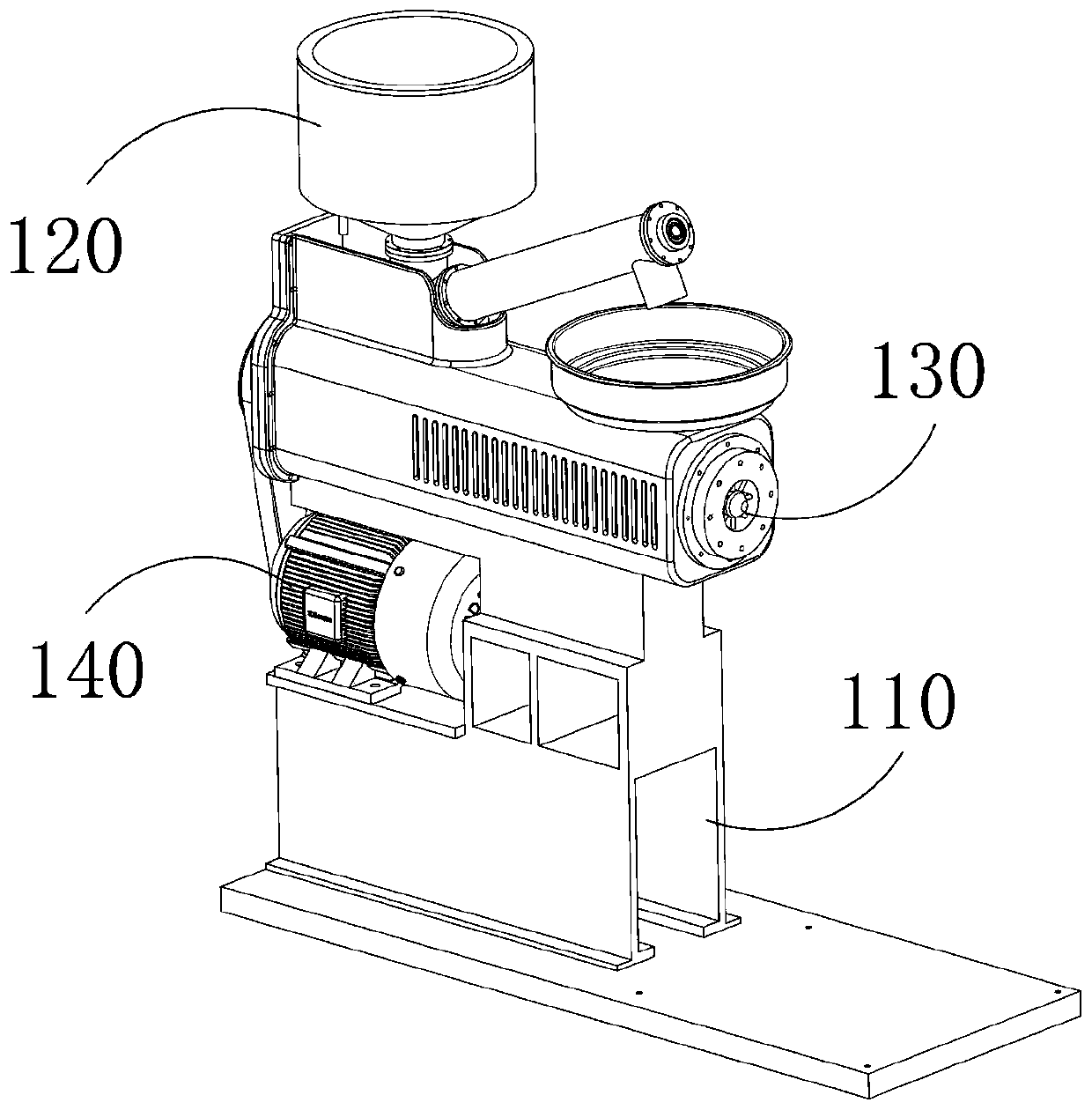

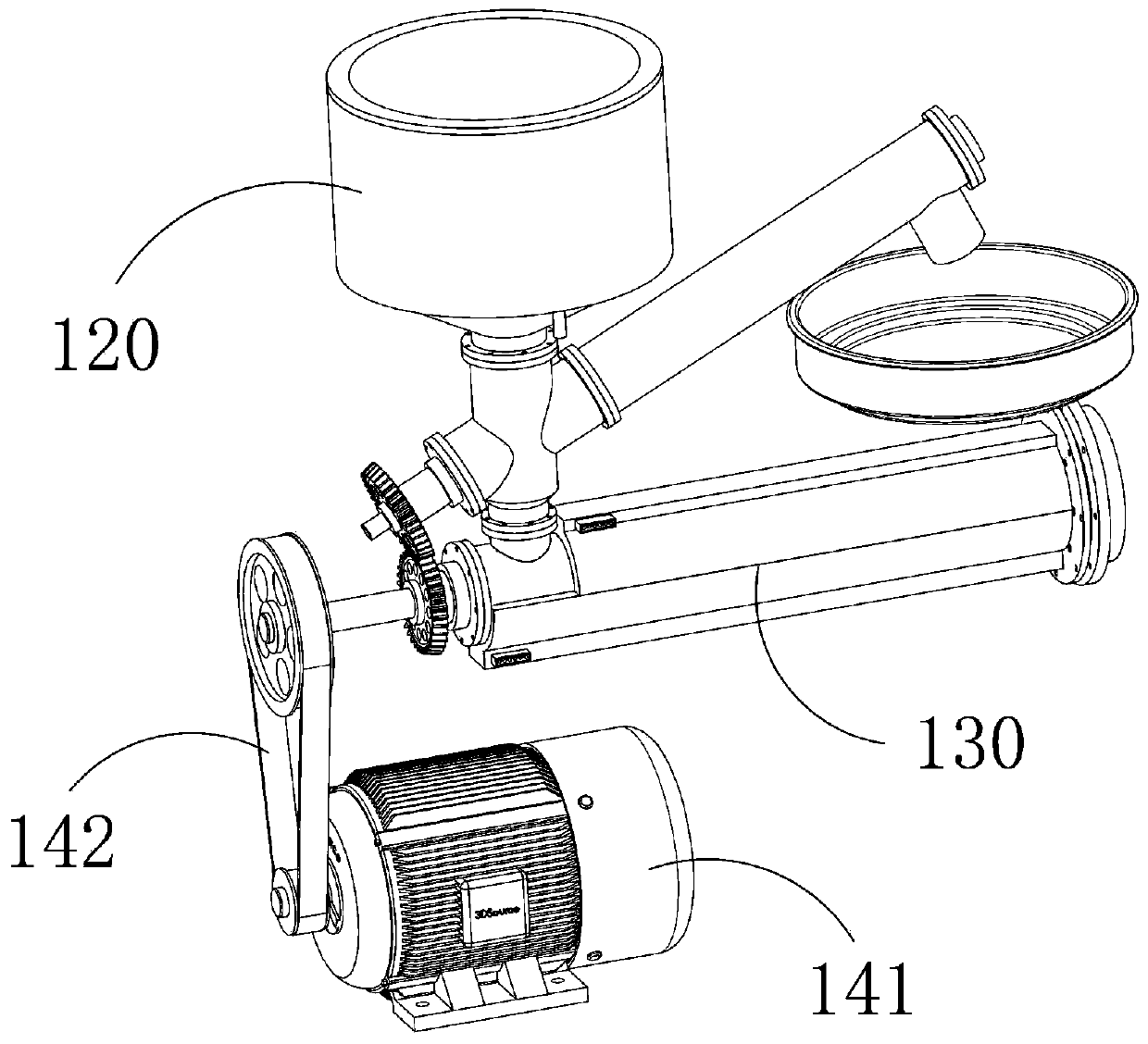

Plastic particle extrusion molding assembly

A technology of extrusion molding and plastic granules, which is applied in the field of plastic recycling and reuse, and can solve the problems of inconsistent size of plastic granules, affecting sales, and low quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention sequentially heats and melts plastic fragments, filters impurities, conveys them in molten state, water-cools them into strips, cuts particles, and obtains plastic particles. In order to avoid frequent replacement and maintenance of the filter screen; during the conveying process, the heating element can keep the plastic in a molten state and be conveyed to the pellet forming device, reducing the probability of clogging; during the water-cooled strip forming process, the cooling water It is flowing water and the cooling water is turned over in the eddy current mode, and the combination of the two has a better effect on the cooling and molding of strip plastics; during the particle cutting process, except for the first test run, the size of the plastic particles obtained during the subsequent normal operation of the present invention Consistent, no need for screening, better quality, more convenient for subsequent sales, and more plastic particles ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com