A New Type of Sealing Device for Empty Rolling Mill Motor

A sealing device and air pass technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of waste of electric energy, aggravate the wear of double lip seals, increase production costs, etc., to reduce production costs, reduce workload, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

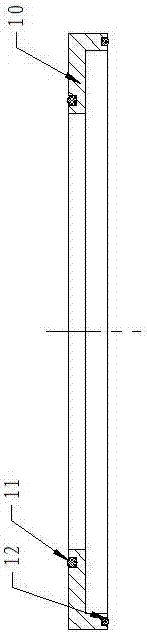

[0019] Embodiment 1: see Figure 4 , a new type of air-pass rolling mill motor sealing device, the sealing device includes an inner slip ring 1 and an outer slip ring 6, a first O-ring 2 and a second O-ring 7, a double-lip seal ring 5, and an eccentric disc 9 , the double-lip sealing ring and the second O-ring are set on the eccentric disk 9, the first O-ring is set in the groove of the inner slip ring 1, and the first O-ring is set on the outer slip ring 6 The sealing device also includes a static sealing ring 10 which is arranged on the upper surface of the outer sliding ring 6 . The overall structure of the sealing device is ingeniously and compactly designed, and a static sealing ring is added, which can meet the rolling requirements of the wire rod mill being empty and the motor is disabled, ensuring that the cooling water of the finishing mill does not enter the thin oil station to pollute the lubricating oil, and stop the relevant Corresponding to the rolling motor to ...

Embodiment 2

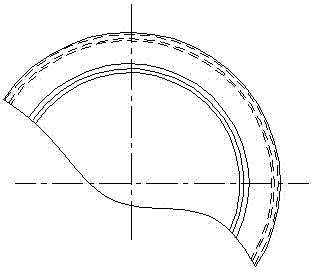

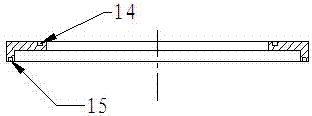

[0020] Example 2: see figure 1 , figure 2 , image 3 , Figure 4 , as an improvement of the present invention, an upper O-ring groove 14 is arranged on the top of the static sealing ring 10, and a lower O-ring groove 15 is arranged on the lower side of the static sealing ring; the sealing device also includes an upper O-ring groove 14; Type ring 11 and lower O-ring 12, the upper O-ring 11 is set in the upper O-ring groove 14; the lower O-ring 12 is set in the lower O-ring groove 15, and the O-ring and the O-ring groove are mutually Fit seal. Thereby, the double-lip seal can be completely isolated from external cooling water, iron oxide scale and other sundries, so that the purpose of saving electric energy can be achieved. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0021] Embodiment 3: see Figure 4 , as an improvement of the present invention, the sealing device also includes a splayed plate 8, the splayed plate 8 is arranged on the surface of the rolling mill box 13, and is bonded to the mating surface of the eccentric disc 9 through the second O-ring 7; The above-mentioned sealing device also includes a hollow protective cap 4, which is arranged on the static sealing ring 10, and the protective cap is pressed tightly by the locking bolt, so that the upper O-ring 11 and the lower O-ring 12 are deformed, and cling to the empty protective cap 4 and the eccentric disc 9 respectively, so that all parts that may enter the water can be sealed in place, so that the double lip sealing ring 5 is completely isolated from the external cooling water and iron oxide scale and other sundries To prevent iron oxide from accumulating under the lips of the double-lip seals, and prevent water ingress and aging at the position of the double-lip seals in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com