An Infrared Monitoring and Control Method for Continuous Casting Fire Cutting and Post-cutting Conveying Device

An infrared monitoring and control method technology, applied in the direction of electrical program control, manufacturing tools, gas flame welding equipment, etc., can solve the problems of low precision of cutting length and cutting depth, prone to accidents, unstable data transmission, etc., to achieve Improve processing speed and control efficiency, reduce manual intervention operations, and ensure the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

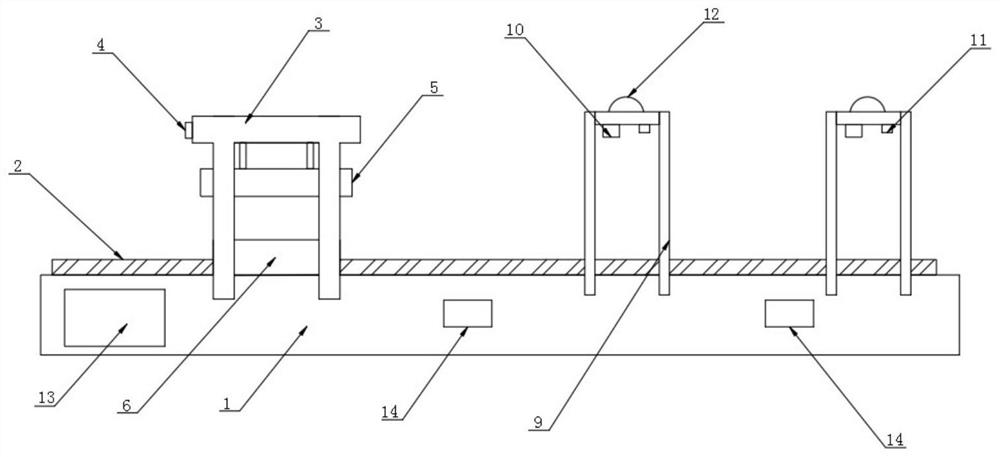

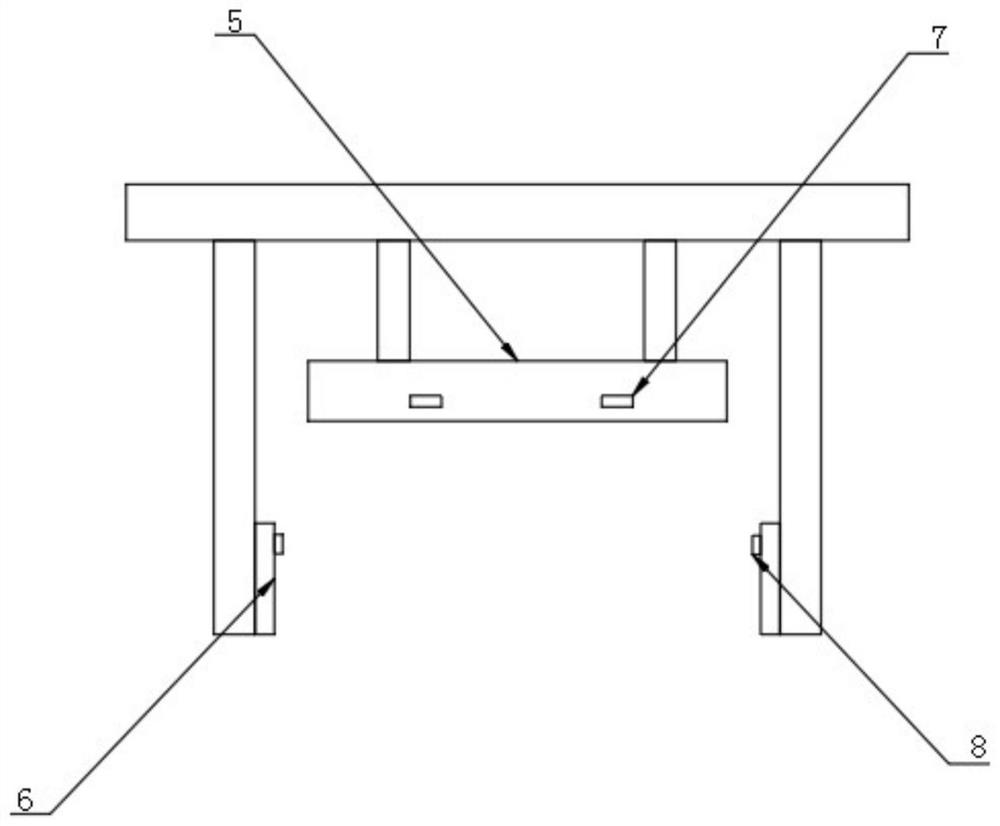

[0025] refer to Figure 1-3 The shown continuous casting fire-cutting and after-cut conveying device includes a cutting transmission device and a support frame, and the cutting transmission device includes a base 1, and a transmission panel 2 is provided on the top surface of the base 1, and the top surface of the transmission panel 2 is A support base 3 is provided, a laser range finder 4 is provided on the top and outside of the support base 3, a cutting mechanism 5 is connected to the bottom of the support base 3, and a clamping mechanism is provided on the front and rear surfaces of the transmission panel 2 6. The outer surface of the cutting mechanism 5 is evenly provided with a first infrared sensor 7, the inner surface of the clamping mechanism 6 is provided with a second infrared sensor 8, and the outer surface of the support seat 3 is evenly provided with a third infrared sensor 10, so The bottom surface of the third infrared sensor 10 is respectively provided with a ...

Embodiment 2

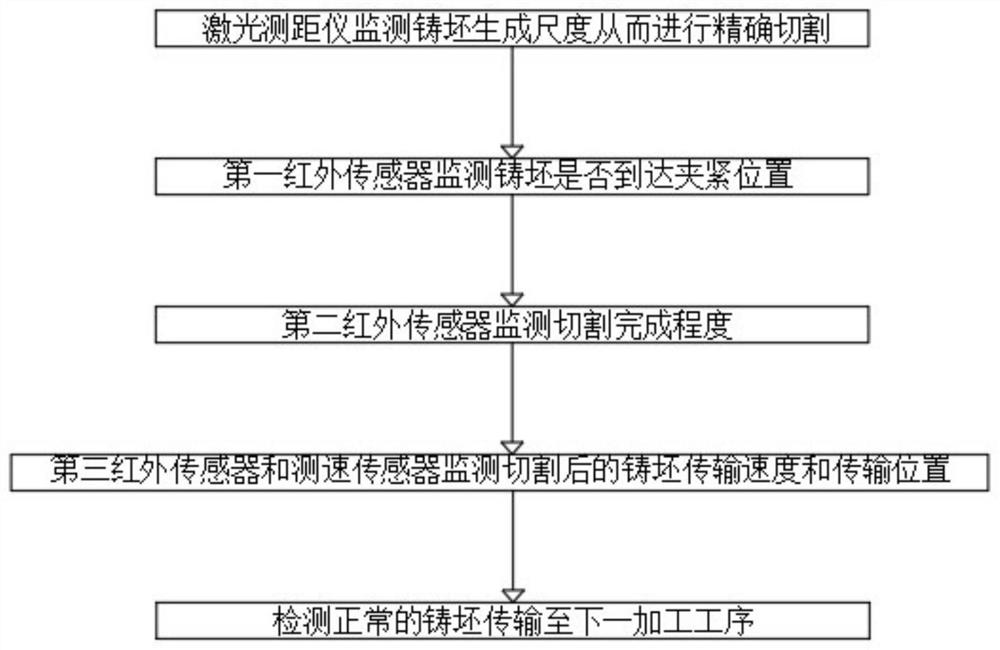

[0032] refer to Figure 1-3 An infrared monitoring and control method for a continuous casting torch cutting and post-cut conveying device includes the following steps:

[0033] Step 1: The slab to be cut is transmitted to the bottom of the support seat 3 on the transmission panel 2, and the laser rangefinder 4 measures and monitors the length of the slab passing through the support seat 3, and the first infrared sensor 7 pairs enter the cutting mechanism at the same time 5 Check whether the slab in the working area has reached the clamping position;

[0034] Step 2: When the predetermined length and position are reached, the clamping mechanism 6 clamps the billet from the front side and the rear side, and the cutting mechanism 5 cuts the clamped billet. During the cutting process, the second infrared sensor 8 monitors the cutting mechanism 5 Cutting completion degree, the cutting mechanism 5 and the clamping mechanism 6 stop working after reaching the predetermined specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com