Full-automatic cutting equipment for stainless steel pipes

A technology for cutting equipment and stainless steel pipes, which is applied in the field of automatic cutting equipment for stainless steel pipes, which can solve the problem of uneven cutting edges, achieve the effect of flat blades and prevent position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029] see Figure 1-Figure 12 , the specific embodiments of the present invention are as follows:

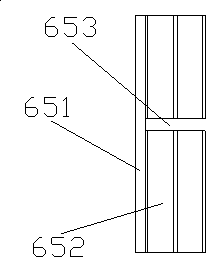

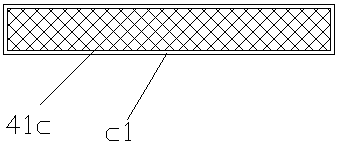

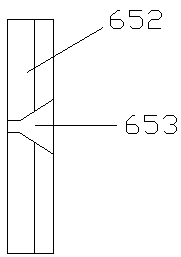

[0030] Its structure includes a frame 1, a cylinder 2, a workbench 3, a motor 4, a cutting blade 5, and a clamping structure 6. The cylinder 2 is installed on the inside of the frame 1 and is mechanically connected, and the workbench 3 is installed horizontally on the machine. The upper end of the frame 1 is welded, the motor 4 is hinged to the upper end of the cylinder 2 and located above the workbench 3, the motor 4 is connected to the cutting blade 5 through a chain, and the clamping structure 6 is horizontally installed on the workbench 3 above and below the cutting blade 5; the clamping structure 6 includes a telescopic cylinder 61, a limiting plate 62, a chassis 63, a movable structure 64, a fixed structure 65, and a guide rod 66, and the limiting plate 62 is welded vertically on On the upper end of the chassis 63, the telescopic cylinder 61 is installed on the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com