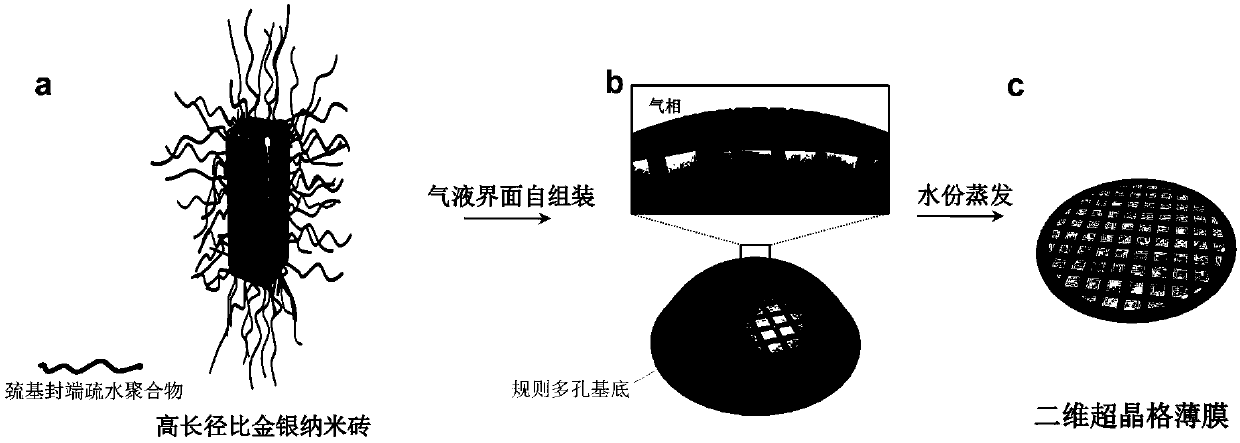

Two-dimensional flexible precious metal nanoparticle superlattice film and construction method and application thereof

A technology of nanoparticles and precious metals, applied in nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of limiting the application range of flexible materials, difficult to transfer, etc., achieve good Raman enhanced detection effect, and avoid the difference of detection results Sexuality, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

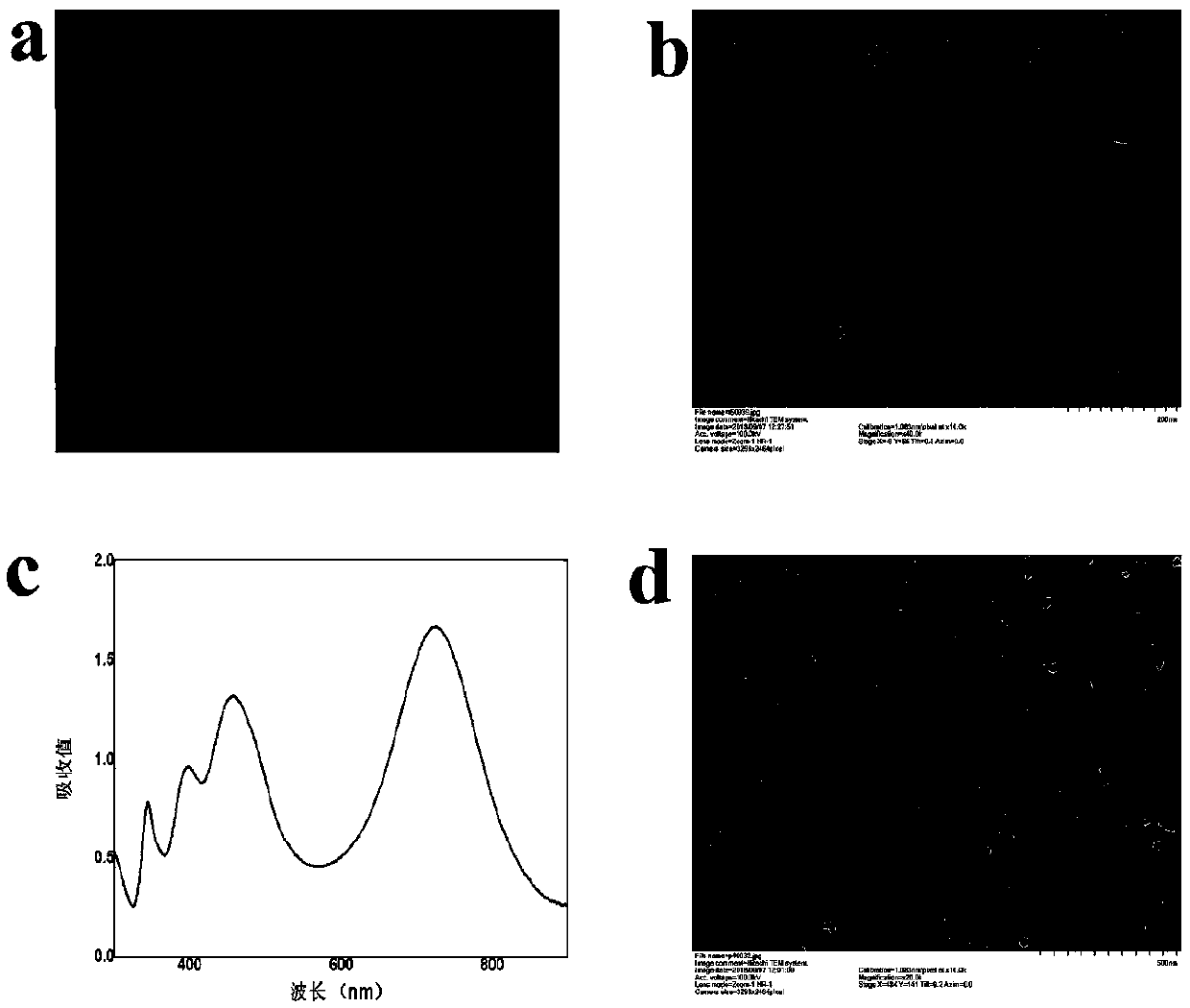

[0051] 1. Mix 5mL 0.2M CTAB aqueous solution and 5mL 0.5mM chloroauric acid aqueous solution thoroughly, add 0.6mL 0.01M sodium borohydride aqueous solution prepared with ice water, stir vigorously for 3-5 minutes to obtain the gold nanorod seed solution, 30℃ Let stand for 2 hours for later use; mix 25mL of a mixed aqueous solution containing 0.1M CTAB and 0.02M 5-bromosalicylic acid with 1.8mL of 4mM silver nitrate aqueous solution. Let stand at 30℃ for 15min, add 25mL of 1mM chloroauric acid aqueous solution, mix and stir. After 15 minutes, 0.2 mL of 64 mM ascorbic acid aqueous solution was added and mixed, the solution became colorless, 40 μL of the prepared seeds were added, and the mixture was mixed and placed at 30°C for 12 hours. Centrifuge the obtained gold nanorods and add an equal volume of deionized water to resuspend.

[0052] 2. Centrifuge the gold nanorods obtained in step 1 with 10mL, remove the supernatant and add the same amount of 80mM CTAC aqueous solution. Rep...

Embodiment 2

[0055] It is the same as embodiment 1, except that:

[0056] In step (1), when preparing the gold nanorod seed solution, the molar ratio of chloroauric acid, cetyltrimethylammonium bromide and sodium borohydride is 1:300:2, the reaction temperature is 25°C, and the reaction time 1h; when the gold nanorod solution is prepared from the gold nanorod seed solution, the moles of chloroauric acid, cetyltrimethylammonium bromide, 5-bromosalicylic acid, silver nitrate, ascorbic acid and the gold nanorod seed solution The ratio is 1:75:15:0.192:0.4:0.01, the reaction temperature is 25°C, and the reaction time is 10h.

[0057] In step (2), the reaction temperature of the reaction in the presence of ascorbic acid and silver nitrate is 70° C., the reaction time is 4 hours, and the mass ratio of gold nanorods, cetyltrimethylammonium chloride, ascorbic acid and silver nitrate It is 1:20:0.7:3.5.

[0058] In step (3), the mass ratio of the high aspect ratio gold core silver shell nanobrick soluti...

Embodiment 3

[0061] It is the same as embodiment 1, except that:

[0062] In step (1), when preparing the gold nanorod seed solution, the molar ratio of chloroauric acid, cetyltrimethylammonium bromide and sodium borohydride is 1:500:3, and gold is prepared from the gold nanorod seed solution In the nanorod solution, the molar ratio of chloroauric acid, cetyltrimethylammonium bromide, 5-bromosalicylic acid, silver nitrate, ascorbic acid and gold nanorod seed solution is 1:125:25:0.384:0.6 : 0.025.

[0063] In step (2), the mass ratio of the gold nanorods, cetyltrimethylammonium chloride, ascorbic acid and silver nitrate is 1:30:2.1:10.5.

[0064] In step (3), the mass ratio of the high aspect ratio gold core silver shell nanobrick solution and the mercapto group-containing modified polystyrene is 1:10.75. The concentration of the tetrahydrofuran solution containing mercapto-modified polystyrene is 3 mg / mL.

[0065] The prepared two-dimensional flexible superlattice film has similar properties to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com