Intelligent monitoring device for ore pulp and foam fullness of flotation cell, and monitoring method thereof

An intelligent monitoring and flotation cell technology, applied in flotation, measuring devices, liquid level control, etc., can solve the problems of high manpower consumption, mineral loss, mineral loss, etc., to ensure the grade and recovery rate, and avoid the loss of minerals , to ensure the effect of smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings.

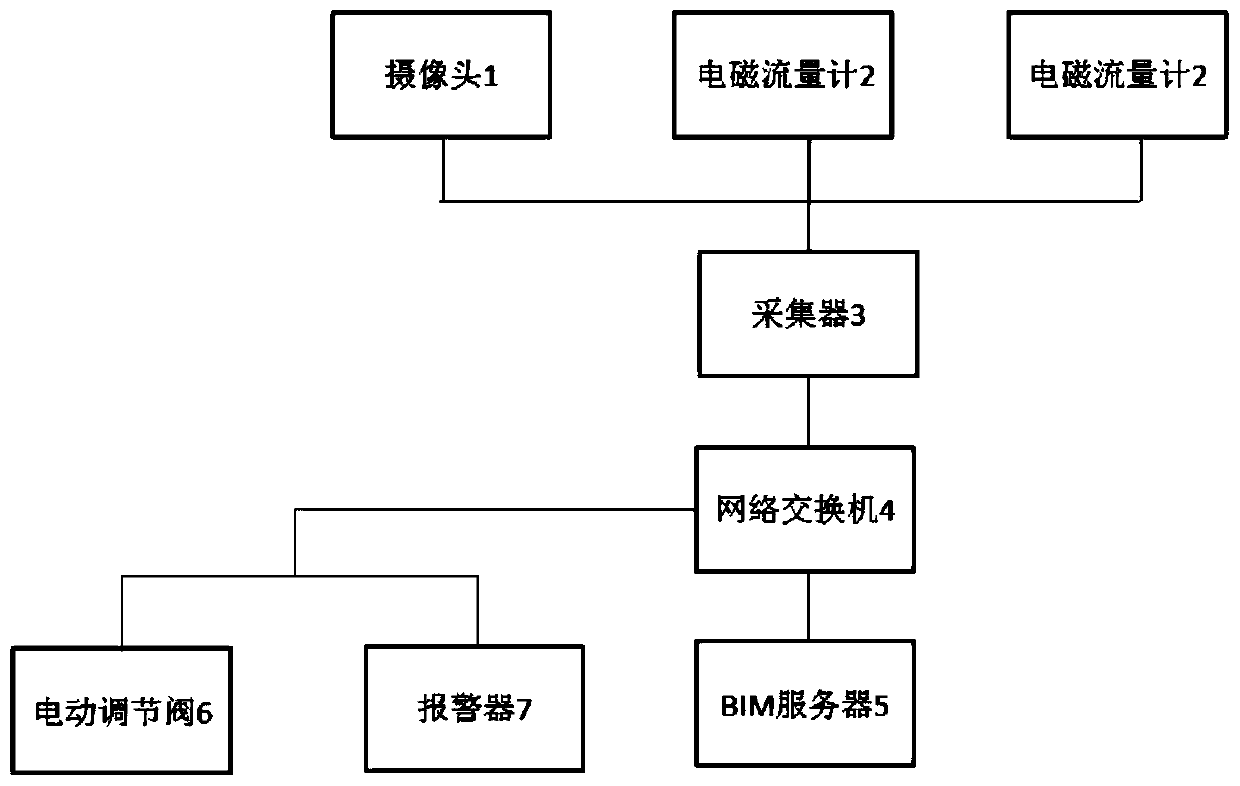

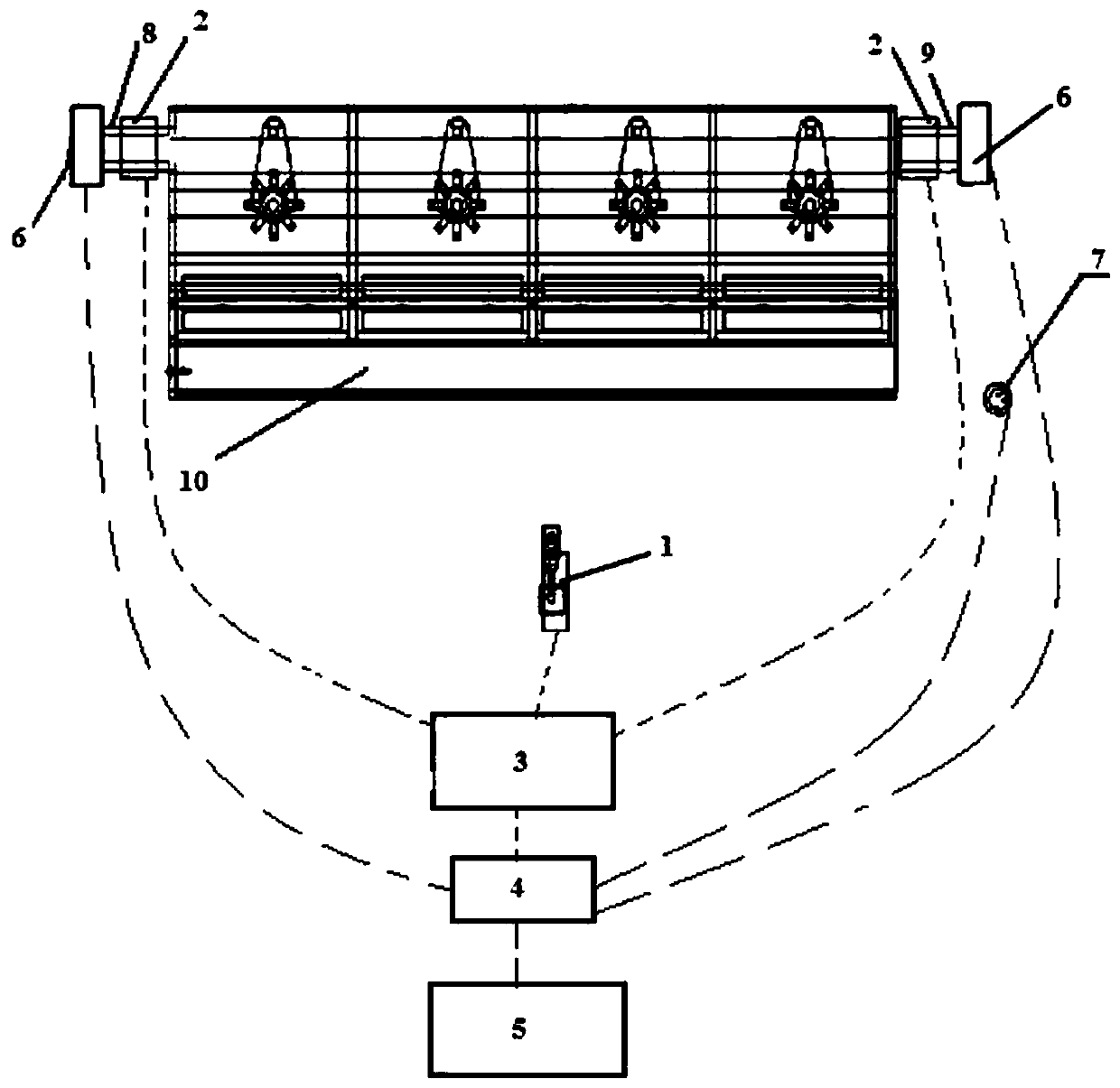

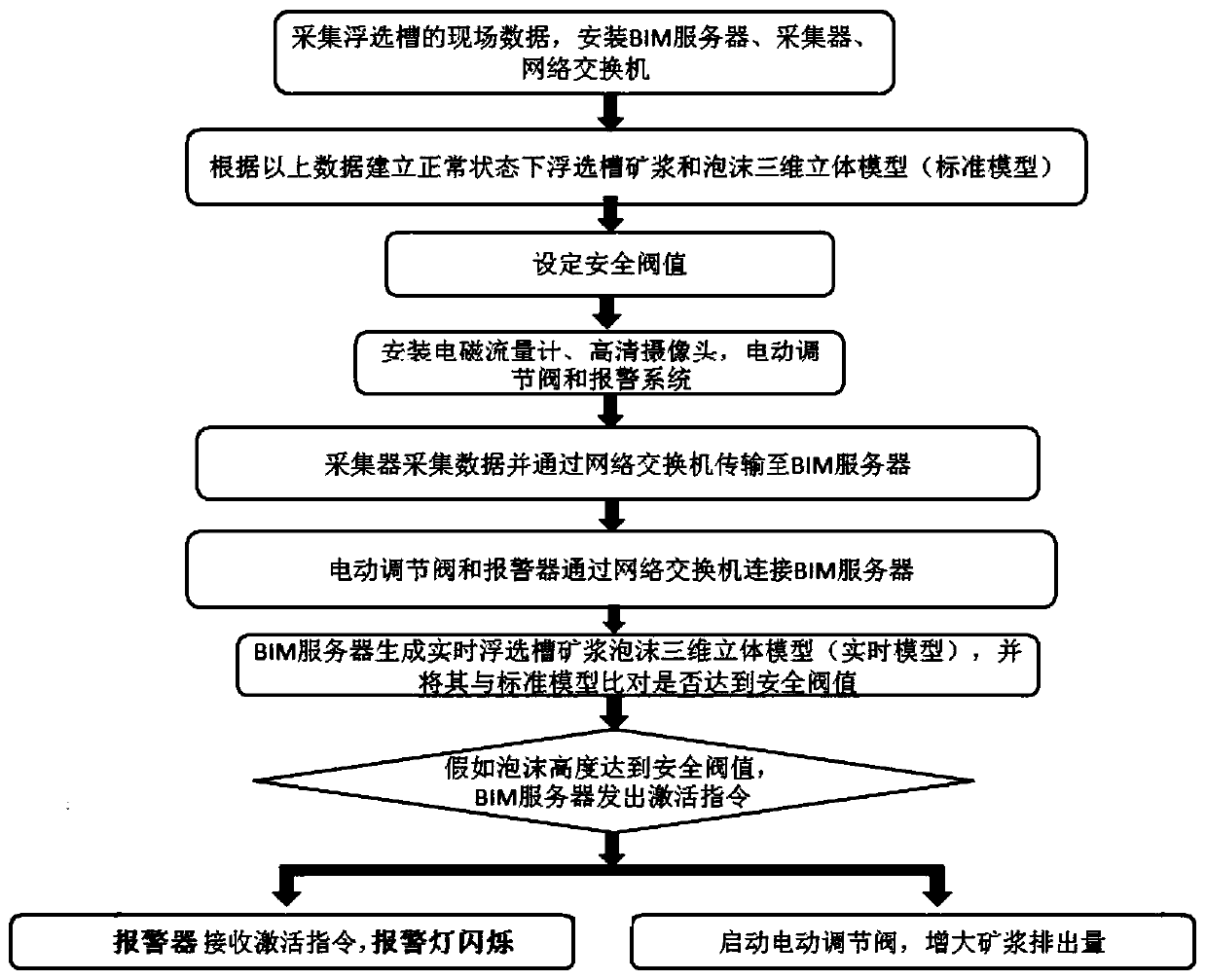

[0021] Working principle of the present invention: as Figure 1-3 , the collector 3 collects various data of the flotation cell 10 on the spot, including the structural data of the flotation cell, the structural data of the flotation machine, the liquid level data of the ore slurry in the tank, the thickness data of the foam layer, the input rate of the ore slurry and the output rate data through the network The switch transmits to the BIM server 5, and the model construction software in the BIM server 5 (that is, in the BIM system) generates a three-dimensional model of the flotation tank slurry foam under normal conditions, and sets it as a standard model, and sets the corresponding foam height Safety threshold; when the flotation cell 10 is working, the camera 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com