Grouting Consolidation Method of Prefabricated Piles Guided by Full-Casing Drilling

A technology of prefabricated piles and full sleeves, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of long engineering period, high engineering cost, and large engineering volume, so as to reduce the difficulty of operation, solve the problem of large engineering volume, The effect of smooth extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

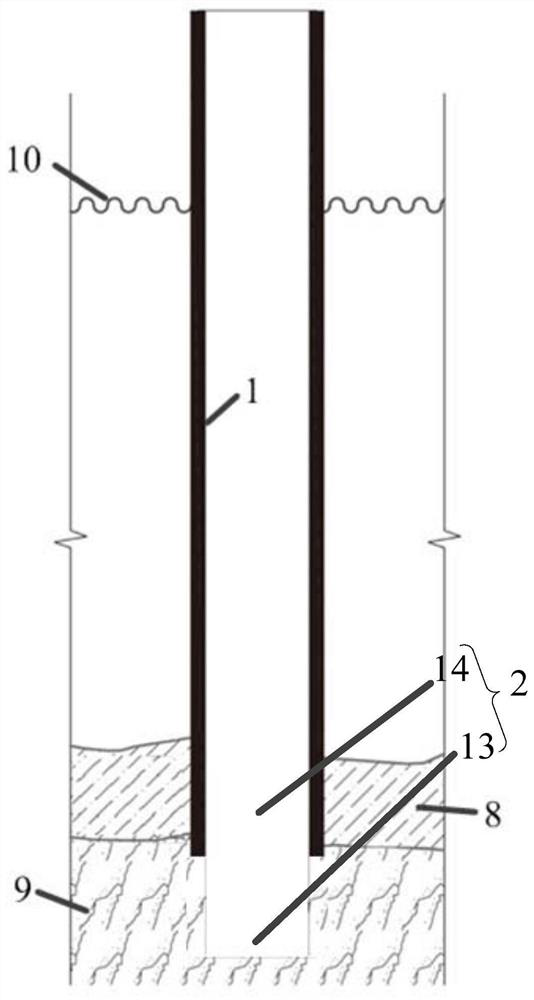

[0057] This embodiment provides a method for grouting consolidation of prefabricated piles guided by full-casing drilling, and its engineering implementation environment is as follows Figure 1 to Figure 7 As shown, in the water area construction process with loose layer 8 and bedrock layer 9 successively at the bottom from top to bottom, the grouting consolidation method of the prefabricated pile guided by full casing drilling includes the following steps:

[0058] Step S1, sinking the casing 1 through the water surface 10 to the loose layer 8, and drilling the loose layer 8 to drive the casing 1 through the loose layer 8 to form a loose layer drilling 14;

[0059] Remove the water and sediment in the casing 1;

[0060] Sink the drill bit of the drilling rig to the bedrock layer through the inner cavity of the casing 1, and drill holes in the bedrock layer to form the bedrock borehole 13 in the bedrock layer;

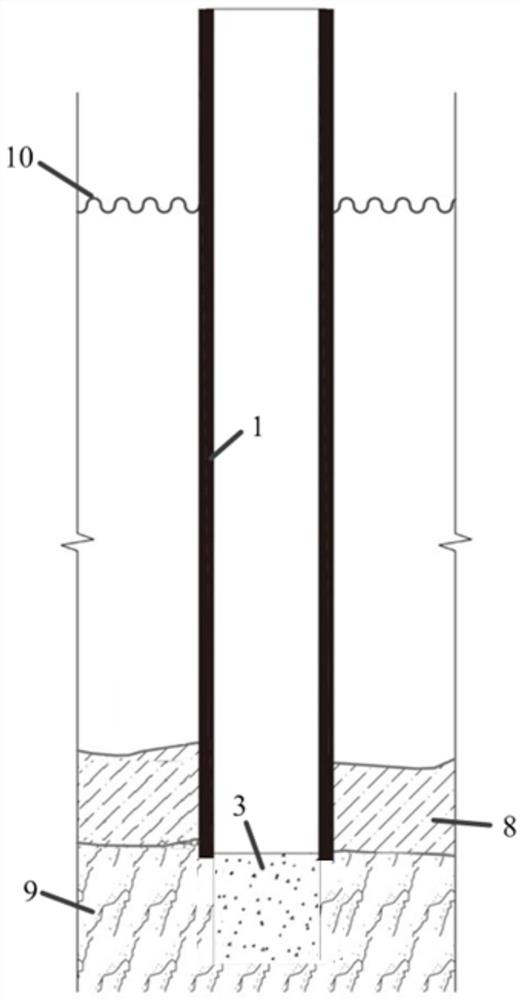

[0061] Step S2, removing the drill bit of the drilling rig from...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is that the engineering implementation environment is a method for grouting consolidation of prefabricated piles guided by full-casing drilling during construction in waters with a bedrock layer 9 at the bottom, including the following steps:

[0076] Step S1, sinking the casing 1 to the bedrock layer; sinking the drill bit of the drilling rig through the inner cavity of the casing 1 to the bedrock layer, and drilling holes in the bedrock layer to drill holes in the bedrock layer forming said bedrock borehole 13;

[0077] Step S2, at this time, the lower end of the casing 1 enters the opening edge of the inner cavity of the bedrock borehole 13, so that the end of the casing 1 is socketed with the opening edge of the bedrock borehole 13, and the The drill bit of the drilling rig is sequentially removed from the bedrock borehole 13 and the casing 1;

[0078] S3, pre-inject grout 3 into the borehole 2; before the gro...

Embodiment 3

[0081] The difference between this embodiment and Embodiment 1 is that the engineering implementation environment is a method of grouting consolidation of prefabricated piles guided by full casing drilling during construction in waters with a loose layer 8 at the bottom, including the following steps:

[0082] Step S1, sinking the casing 1 to the loose layer 8, drilling the loose layer 8 to form a loose layer drilling 14, and driving the casing 1 into the loose layer 8; The sediment in the casing 1 is removed;

[0083] Step S2, the casing 1 is accommodated in the loose layer borehole 14;

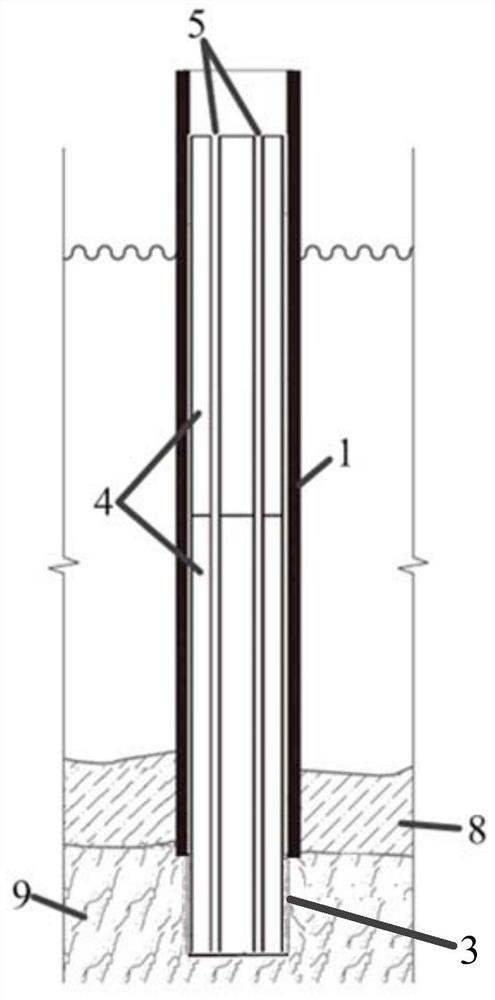

[0084] Step S3, implanting the prefabricated pile 4 into the loose layer borehole 14, so that the prefabricated pile 4 reaches the bottom of the loose layer borehole 14;

[0085] S4, lifting the casing 1, during the ascent of the casing 1, the grouting channel 5 on the prefabricated pile 4 continues to inject grout into the borehole 14 of the loose layer; the grouting channel 5 includes: lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com