Ink printing machine

A printing press and ink technology, applied in printing presses, rotary printing presses, screen printing presses, etc., can solve the problems of clogging of inkjet tubes, affecting inkjet effect, waste, etc., to save material waste, avoid clogging, improve The effect of print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

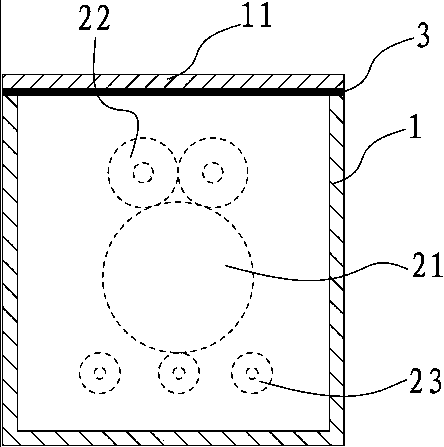

[0011] refer to figure 1 , the present embodiment discloses an ink printing machine, comprising a printing casing 1, a cover plate 11 arranged above the casing, a paper feeding device (not shown) arranged at the front and rear of the printing casing, and a The printing inkjet device in the body 1, the printing inkjet device includes a printing roller 21, two inkjet rollers 22 and three lower pressure rollers 23 arranged in parallel and spaced front and back, and the printing roller 21 is rotatably arranged in the printing shell In the body 1, the two inkjet rollers 22 are rotatably arranged on the upper part of the printing roller 21 in the printing casing 1, and the three lower pressure rollers 23 are respectively rotatably arranged on the printing casing 1 Below the above-mentioned printing roller 21, a non-stick coating layer 3 is provided on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap