A tooling fixture for sharp-angled pipe

A tooling fixture and pipe bending technology, which is applied in the field of sharp-angle bender tooling fixtures, can solve problems such as the inability to clamp sharp-angle bends and the inability to turn over and rotate freely, and achieve the effects of facilitating one-time processing, improving practicability, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

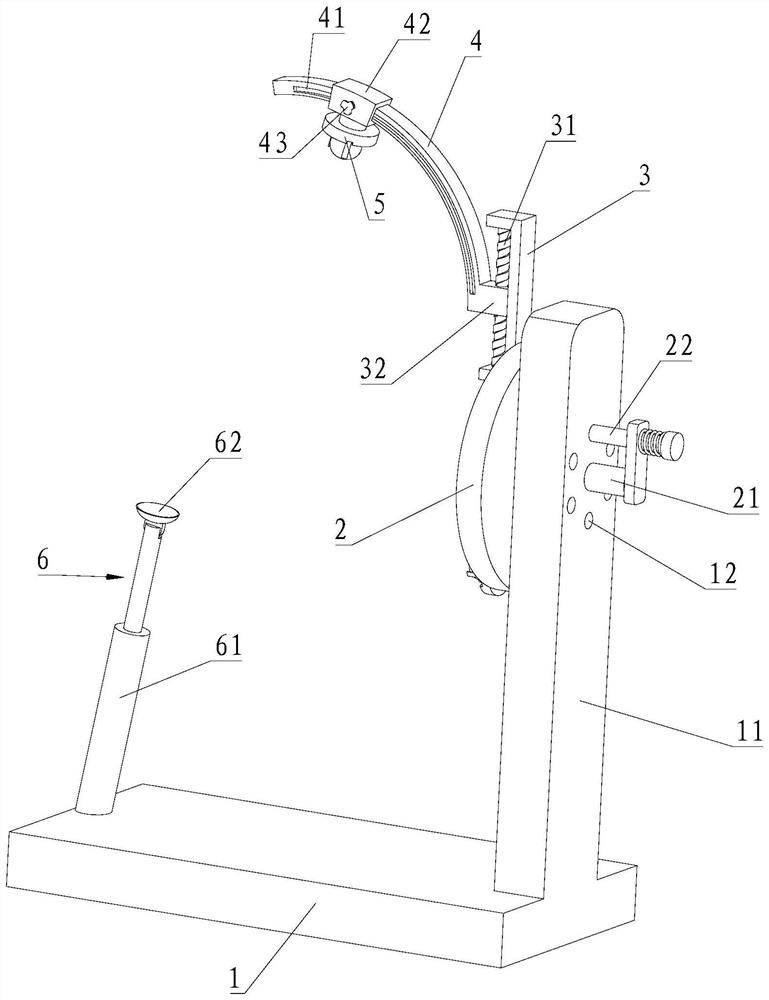

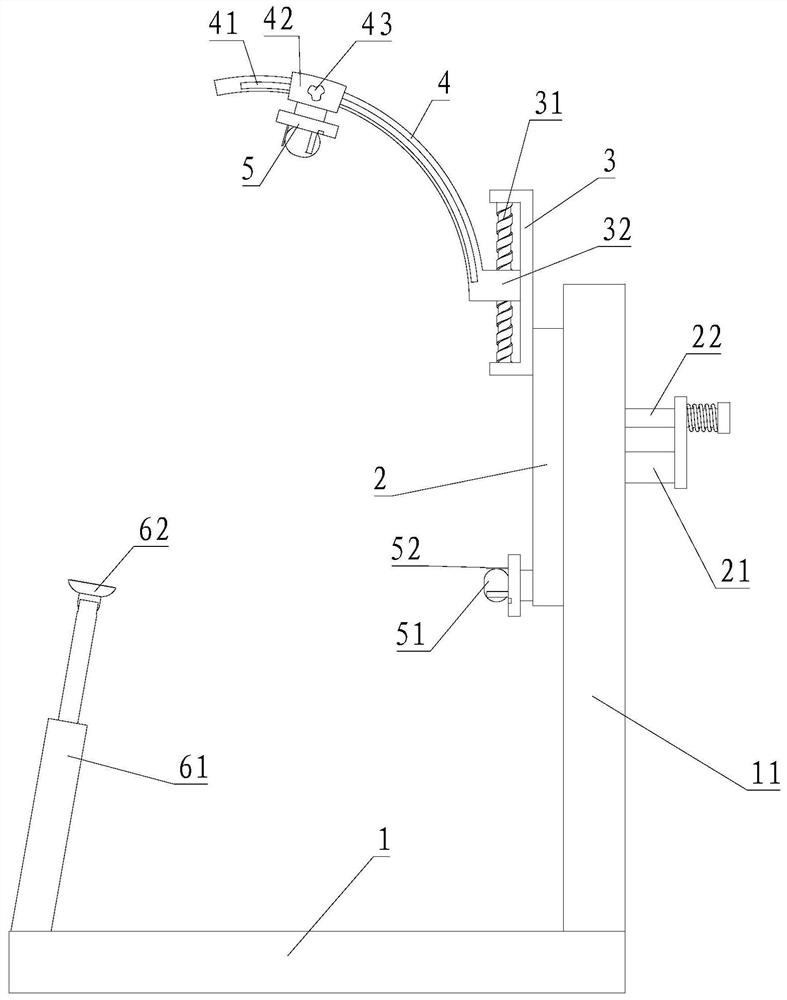

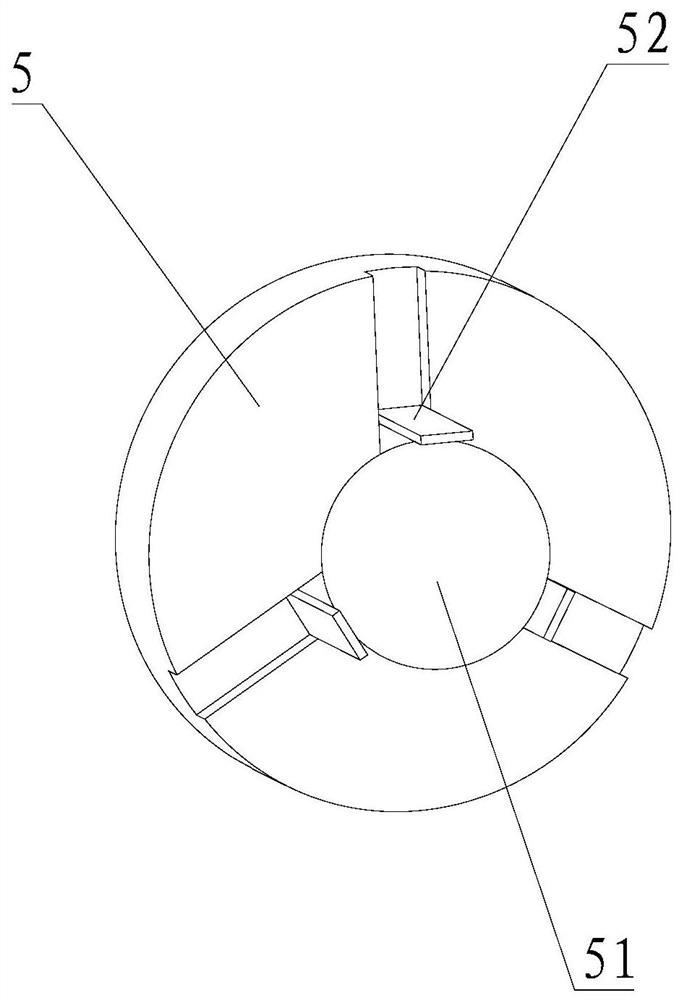

[0046] A tooling fixture for sharp-angled pipes, including a frame 1, a swivel part 2, a height adjustment part 3, an angle adjustment part 4 and two clamping parts 5;

[0047] The rotary part 2 is rotatably connected to the frame 1, and the rotary part 2 rotates around a horizontal axis. The frame 1 is provided with a vertical column 11, and the rotary part 2 is rotatably connected to the top of the column 11. The rotating part 2 is provided with a rotating shaft 21, the rotating shaft 21 passes through the column 11 and is connected to the frame 1 in rotation, the end of the rotating shaft 21 is fixedly connected with a handle perpendicular to the rotating shaft 21, the The handle is elastically connected with a fixed rod 22 parallel to the rotation axis, and the column 11 is provided with a plurality of fixed grooves 12 corresponding to the fixed rods 22, and the fixed rods 22 are clamped in the fixed grooves 12. One end of the fixed rod 22 passes through the handle, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com