Magnetic separator

A magnetic separator and electromagnetic technology, applied in the field of magnetic separators, can solve the problems of cumbersome and complicated magnetic separation process of magnetic substances, inability to completely scrape magnetic substances, and reduce the magnetic separation effect, etc., so as to improve the magnetic separation effect and the material removal process. Thoroughly improve the effect of magnetic separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

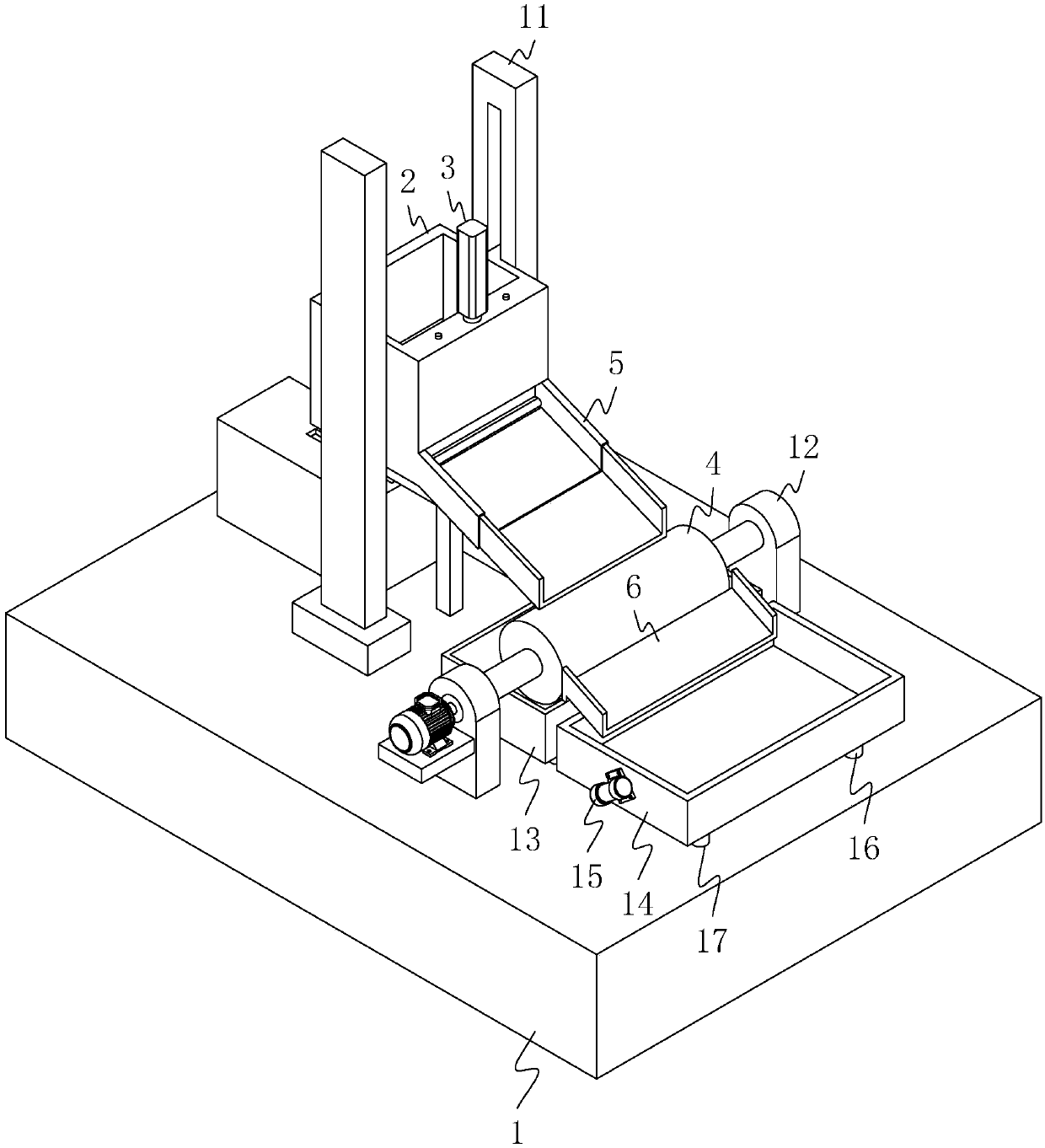

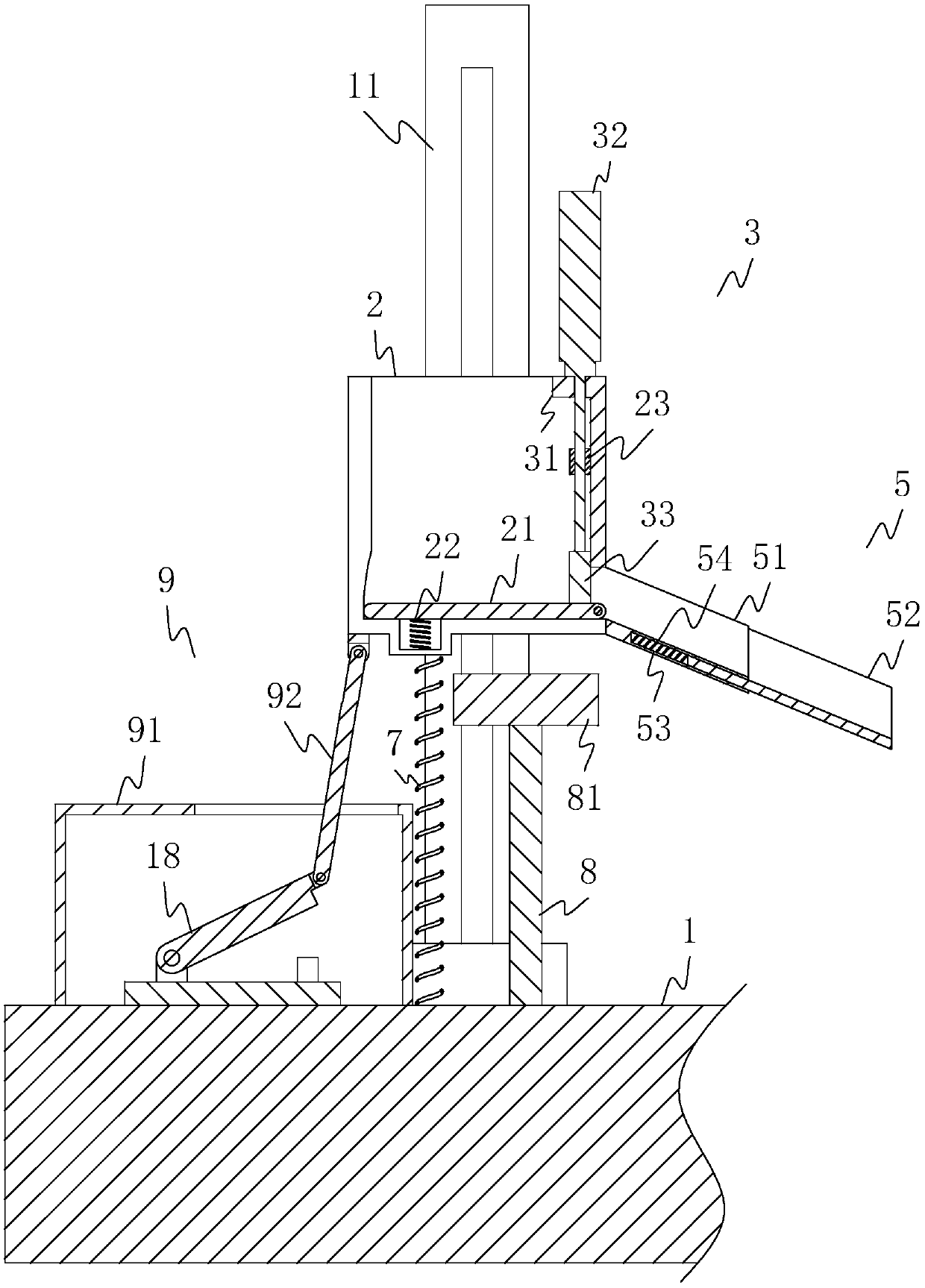

[0033] A magnetic separator, such as figure 1As shown, it includes a base 1, a support frame 11 arranged on the base 1, a material box 2 is arranged on the support frame 11, and a switch part 3 for controlling the discharge of the material box 2 is provided at the discharge end of the material box 2. The base 1 is provided with a support seat 12, the support seat 12 is located below the discharge end of the material box 2, the support seat 12 is rotatably connected with an electromagnetic roller 4, and the base 1 is provided with a chip box 13 positioned at the bottom of the electromagnetic roller 4. Copper material bin 14 at the chip bin 13 rears.

[0034] Such as figure 1 As shown, the position of the discharge end of the material box 2 is provided with a material guide groove 5 arranged towards the direction of the electromagnetic roller 4, and the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com