Low-temperature high-activity nickel-based bimetallic methanation catalyst, preparation method and applications thereof

A technology of methanation catalyst and active metal, which is applied in the field of low-temperature high-activity nickel-based bimetallic methanation catalyst and its preparation, can solve the problems of low utilization rate of metal Ni, easy agglomeration of Ni particles, catalyst deactivation, etc., and achieves the preparation method Simple operation, long catalyst life and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

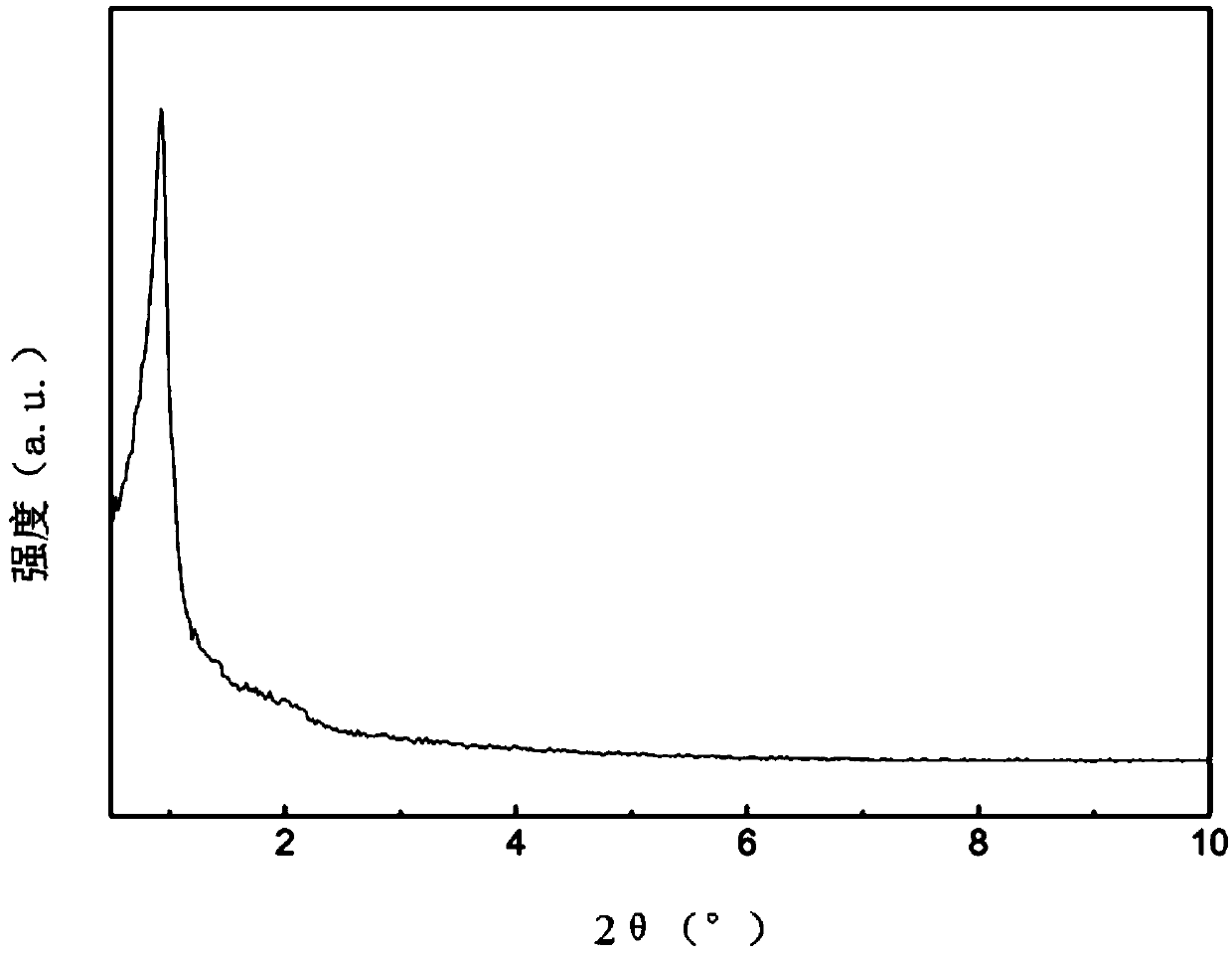

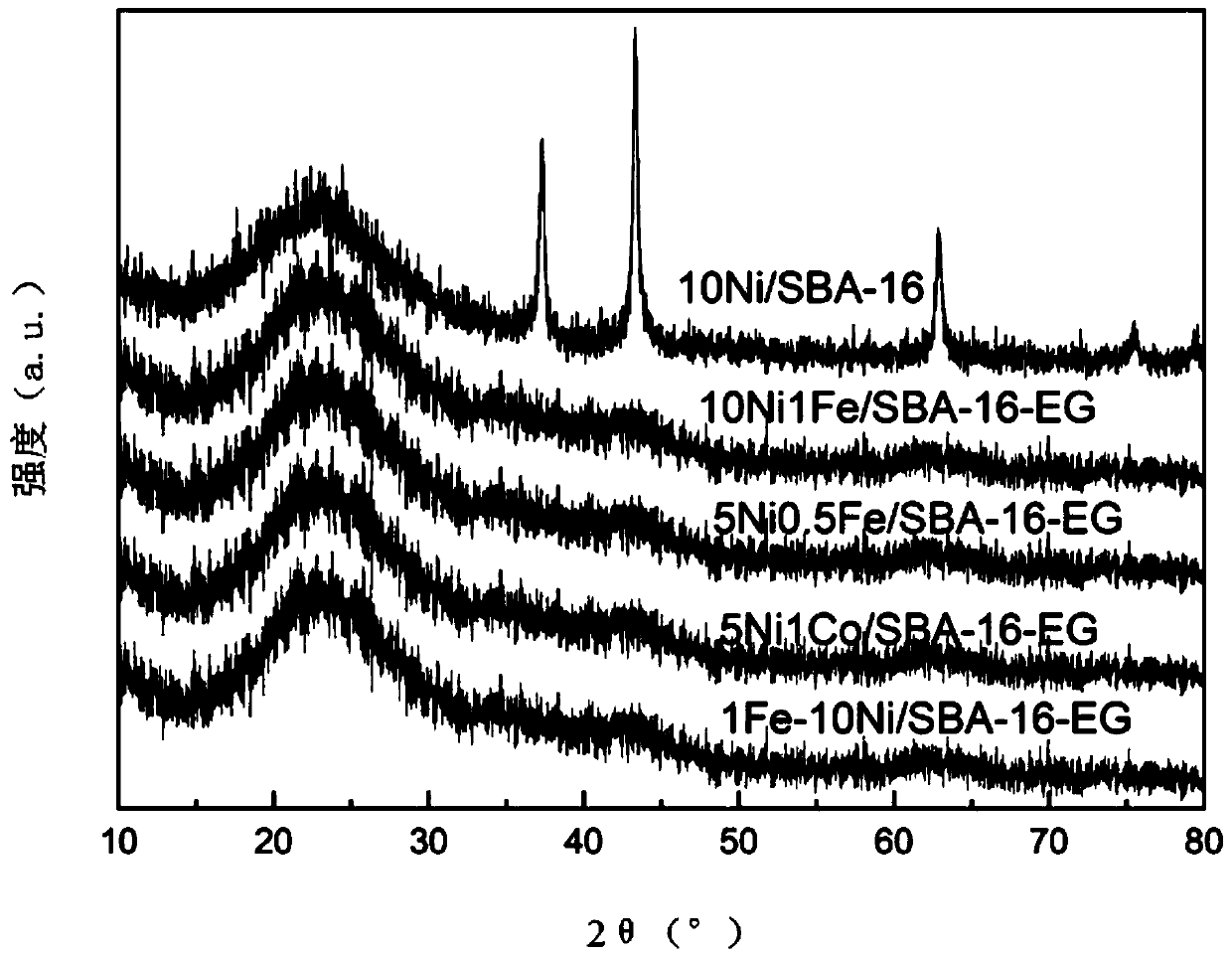

[0052] The dried mesoporous SiO 2 Molecular sieve SBA-16-EG was immersed in ethylene glycol in equal volume, stirred evenly, left at room temperature, and dried to obtain pretreated mesoporous molecular sieve SBA-16-EG with a specific surface area of 887 m 2 / g, the pore wall is 4 nm, and the pore volume is 0.75 cm 3 / g, the pore size was 4 nm; then the pretreated mesoporous molecular sieve dried SBA-16-EG was used in the next step. The mesoporous molecular sieve SBA-16-EG was dried at a temperature of 80°C for 12h.

[0053] Dissolve 0.55g nickel nitrate hexahydrate and 0.08g ferric nitrate nonahydrate in 2.0mL deionized water to prepare an impregnation solution, and impregnate the dried 1.0g pretreated mesoporous molecular sieve SBA-16-EG by an equal volume co-impregnation method In 2.0 mL of the dipping solution, it was allowed to stand for 8 hours, and then dried in a vacuum oven at a temperature of 60° C. for 12 hours. The obtained solid product is roasted in a muffle...

Embodiment 2

[0056] The dried mesoporous SiO 2 Molecular sieve SBA-16-EG was immersed in ethylene glycol in equal volume, stirred evenly, left at room temperature, and dried to obtain pretreated mesoporous molecular sieve SBA-16-EG with a specific surface area of 887 m 2 / g, the pore wall is 4 nm, and the pore volume is 0.75 cm 3 / g, the pore size was 3 nm; then the pretreated mesoporous molecular sieve dried SBA-16-EG was used in the next step. The mesoporous molecular sieve SBA-16-EG was dried at a temperature of 120 °C for 8 hours.

[0057] 0.23 g of nickel nitrate hexahydrate and 0.04 g of ferric nitrate nonahydrate were dissolved in 2.0 mL of deionized water to prepare an impregnation solution, and the dried 1.0 g of pretreated mesoporous SiO was prepared by an equal volume co-impregnation method. 2 The molecular sieve SBA-16-EG was immersed in 2.0 mL of the immersion solution, allowed to stand for 6 hours, and then dried in a vacuum oven at a temperature of 60° C. for 8 hours. T...

Embodiment 3

[0060] The dried mesoporous SiO 2 Molecular sieve SBA-16-EG was immersed in ethylene glycol in equal volume, stirred evenly, left at room temperature, and dried to obtain pretreated mesoporous molecular sieve SBA-16-EG with a specific surface area of 887 m 2 / g, the pore wall is 4 nm, and the pore volume is 0.75 cm 3 / g, the pore size was 6 nm; then the pretreated mesoporous molecular sieve dried SBA-16-EG was used in the next step. The mesoporous molecular sieve SBA-16-EG was dried at a temperature of 100 °C for 12 hours.

[0061] Dissolve 0.34g of nickel acetate hexahydrate in 2.0mL of deionized water to prepare a nickel salt solution, dissolve 0.08g of ferric nitrate nonahydrate in 2.0mL of deionized water to prepare a ferric nitrate solution, and use the equal volume immersion method to first immerse the dried 1.0 g of pretreated mesoporous SiO 2 Molecular sieve SBA-16-EG was immersed in 2.0 mL of ferric nitrate solution, allowed to stand for 6 h, then dried in a vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com