Stator assembly method and stator assembly device

An assembly method and a technology for assembling devices, which are applied in the direction of electromechanical devices, windings, electric components, etc., can solve the problems of inability to properly ensure the insulation performance of the slot receiving part and the slot, and the shape of the insulating part is damaged, so as to ensure insulation and prevent The shape is destroyed and the effect of reliable insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] [Structure of the stator]

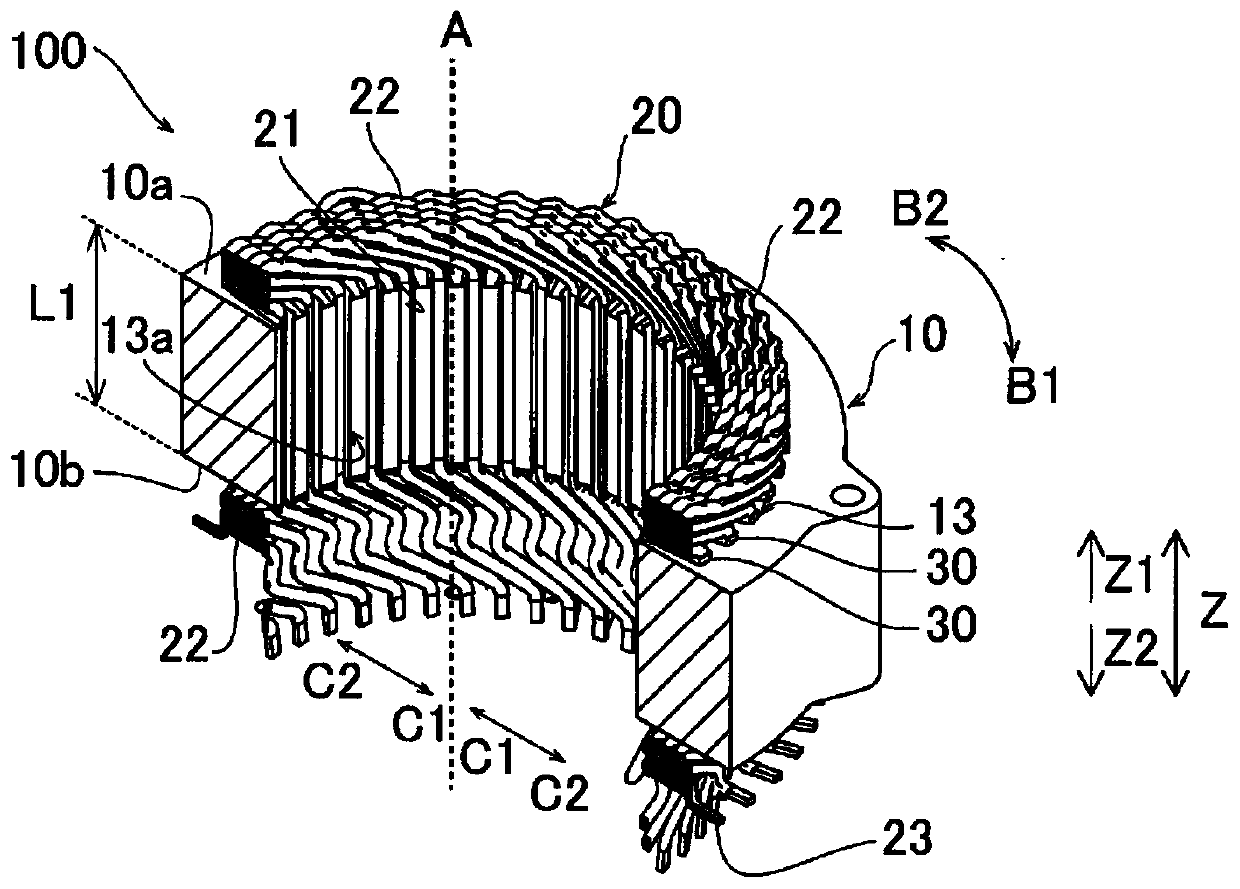

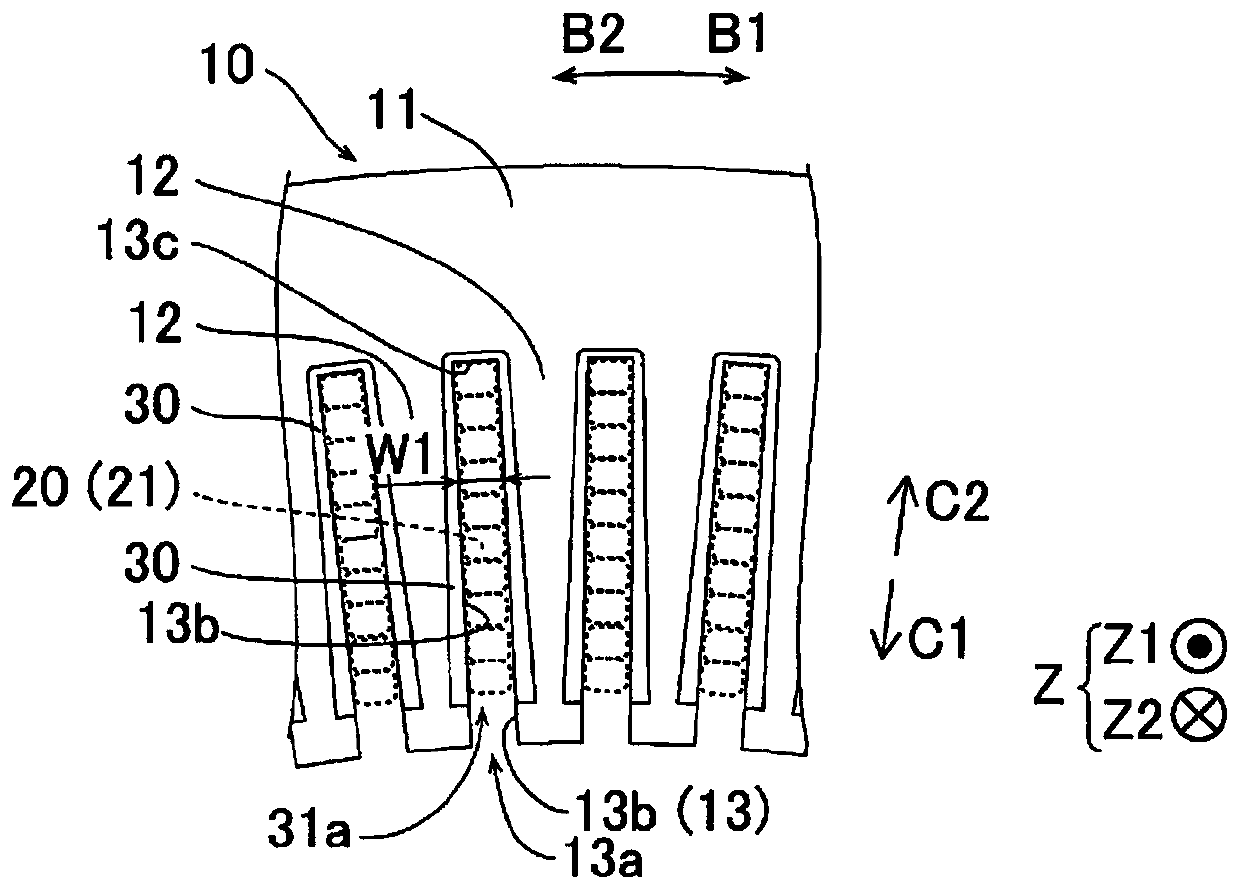

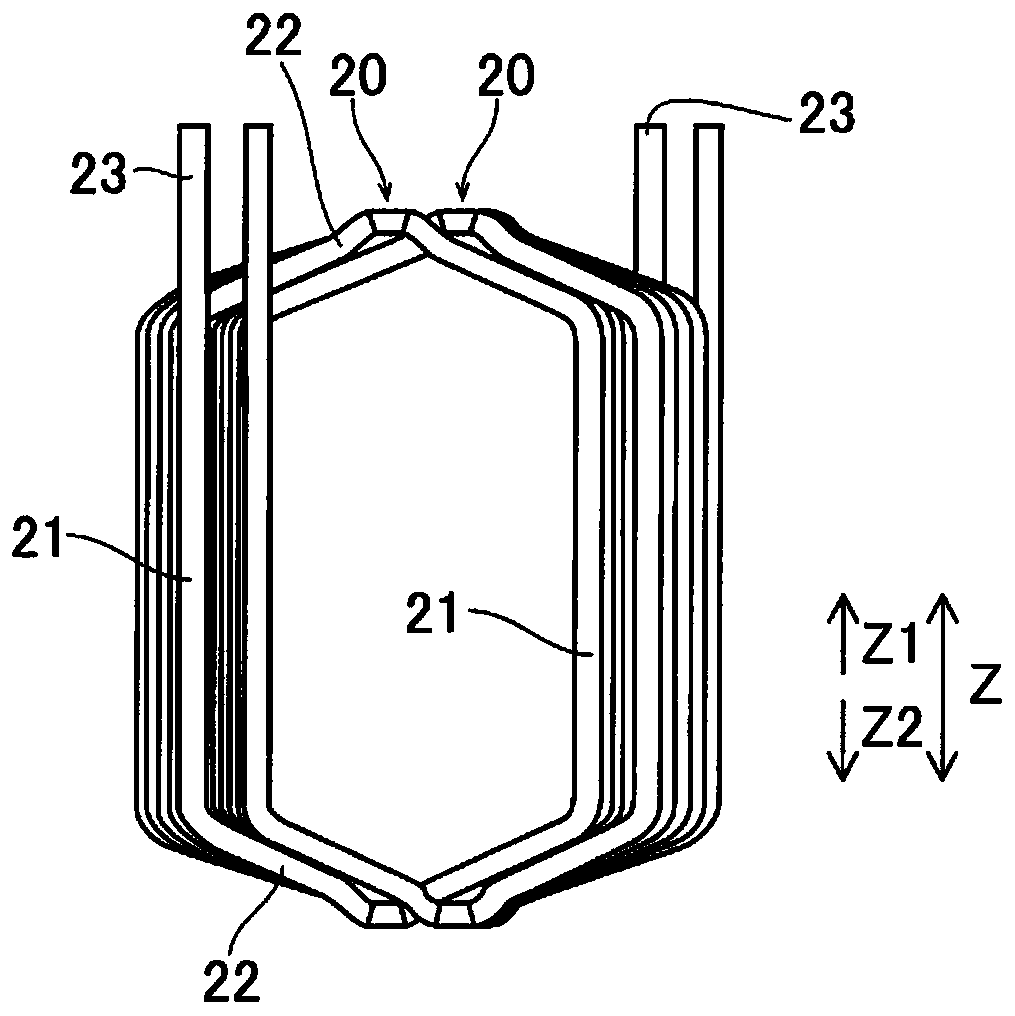

[0037] Reference Figure 1 ~ Figure 4 The structure of the stator 100 of this embodiment is demonstrated. In addition, in figure 1 Although the oblique cross-sectional view (semi-circular shape) of the stator 100 is shown, the stator 100 is formed in a circular ring shape.

[0038] In addition, in the specification of this application, "central axis direction" and "axial direction" mean along figure 1 The direction (Z direction) of the central axis A (rotation axis of the rotor) of the stator core 10 (stator 100) shown. In addition, the "circumferential direction" is the circumferential direction (the B1 direction or the B2 direction) of the designated sub-core 10. In addition, the “radial direction” refers to the radial direction of the designated sub-core 10. In addition, "radially inner side" refers to the direction (C1 direction) towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com