Numerical control full-automatic assembling machine for built-in contact reed of rectangular heavy-load electric connector

A technology of electrical connectors and contact reeds, which is applied in the field of built-in contact reed CNC automatic assembly machines, can solve the problems of poor product consistency, heavy labor, low assembly efficiency, etc., to reduce failure rates, reduce labor costs, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0034] The "upper" and "lower" mentioned in this article refer to the upper and lower positions where the machine is normally placed. The "front" and "rear" take the side of each mechanism facing the workbench as the front, and vice versa as the rear.

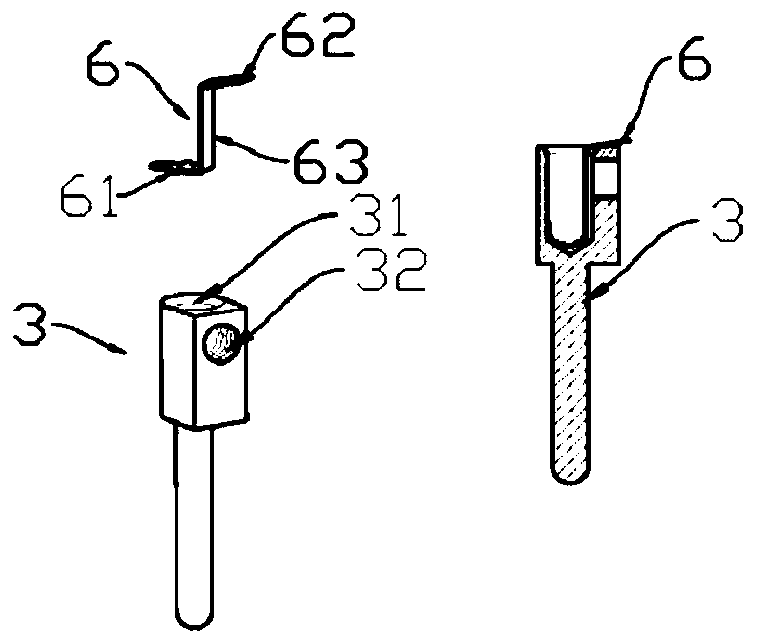

[0035] The function of the built-in contact reed numerical control automatic assembly machine of the rectangular heavy-duty electrical connector of the present invention is to figure 1 The middle reed 6 is assembled on the workpiece 3 , specifically, the clamping portion 61 of the reed 6 is clamped in the reed hole 31 of the workpiece 3 .

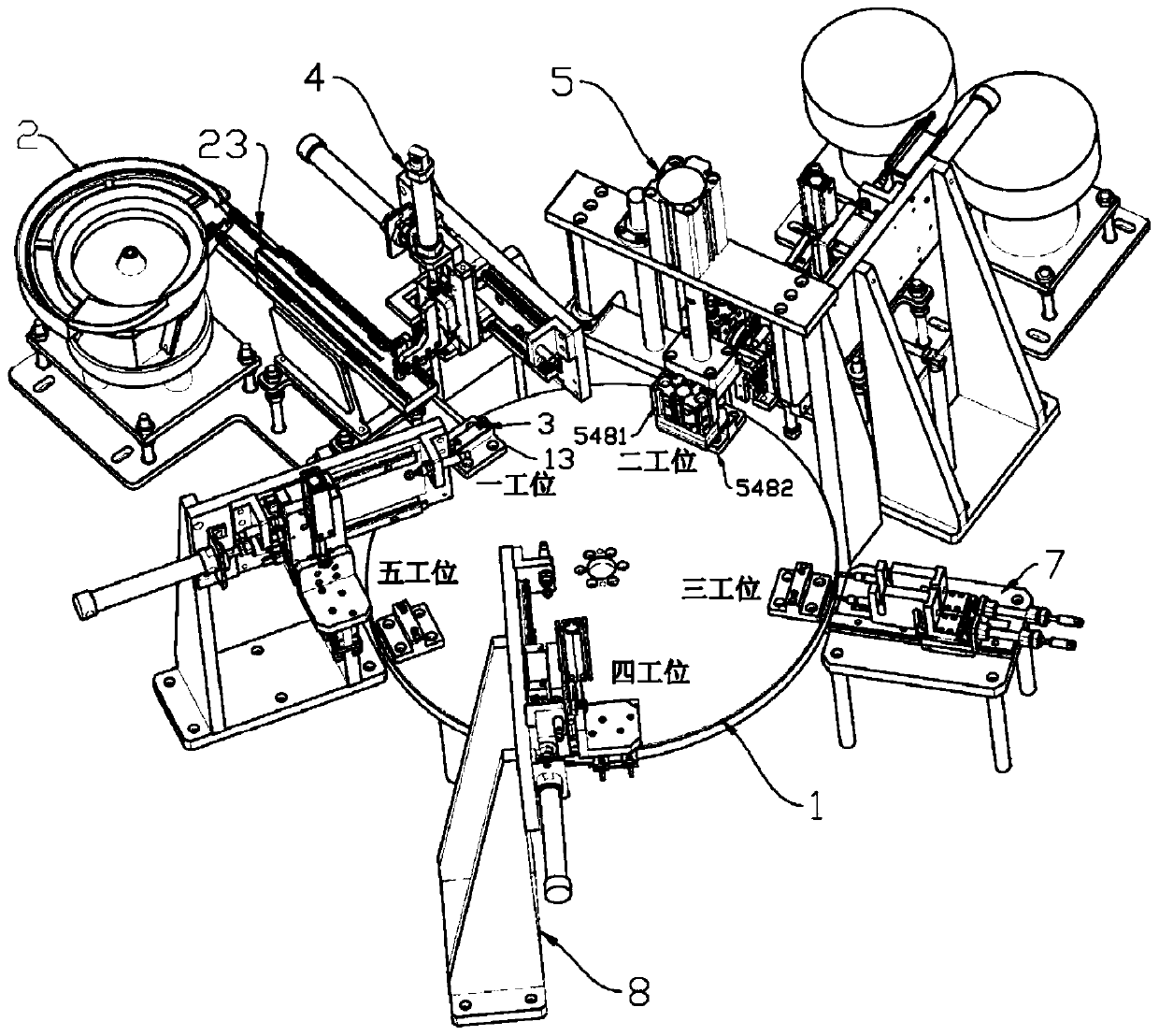

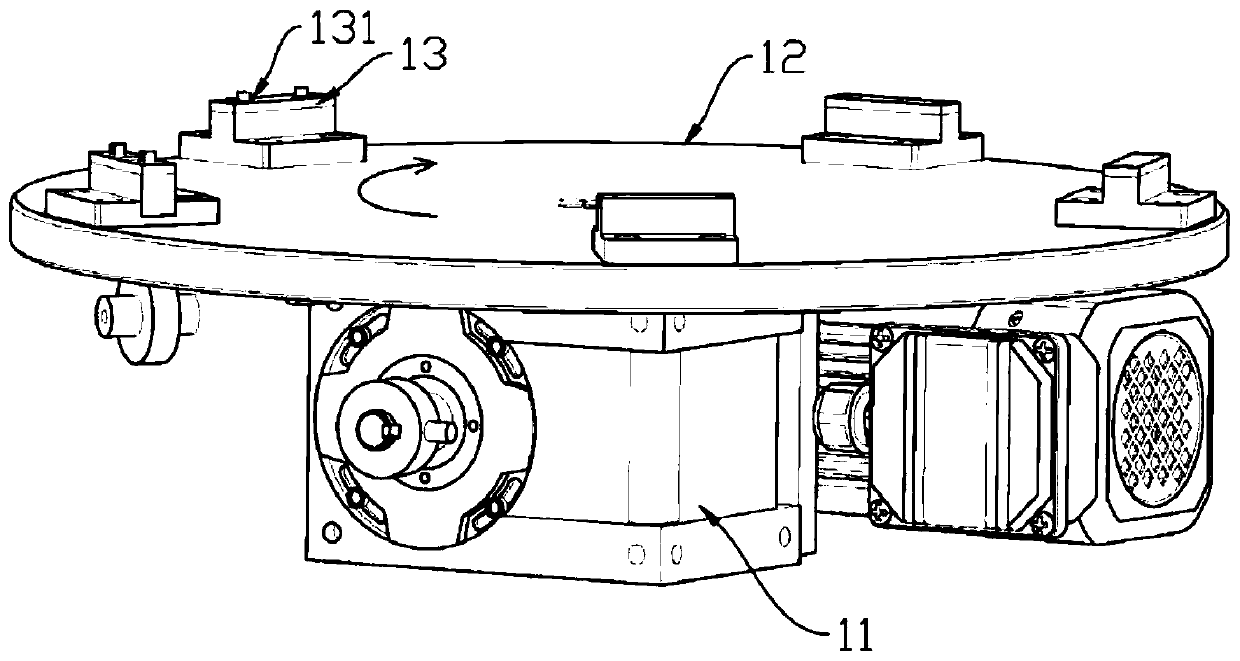

[0036] like figure 2 As shown, the CNC automatic assembly machine for built-in contact reeds of rectangular heavy-duty electrical connectors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com